Seed drying device

A drying device and seed technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems that seeds cannot be heated and dried, uneven drying, etc., to save manpower, improve flexibility, and evenly feed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

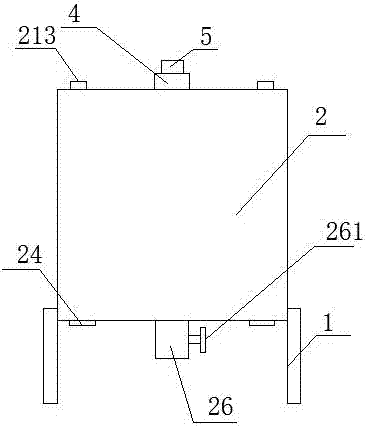

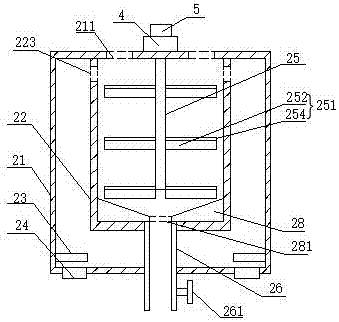

[0033] As shown in Figure 1, it is a schematic structural view of a seed drying device in Embodiment 1, including a frame 1 and a drying barrel 2 arranged on the frame 1, and the top of the drying barrel 2 is provided with at least two feeders. mouth 211, the bottom of the drying barrel 2 is provided with a discharge pipe 26, the discharge pipe 26 is provided with a valve 261, the drying barrel 2 includes an outer barrel body 21 and an inner barrel body 22, and the top of the inner barrel body 22 is connected to the top of the outer barrel body 21 , the inner barrel body 22 and the outer barrel body 21 have the same axis line, and the discharge pipe 26 runs through the inner barrel body 22 and the outer barrel body 21 .

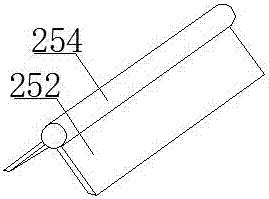

[0034] Such as figure 2 Shown is a cross-sectional view of a drying barrel of a seed drying device in Embodiment 1. A heating pipe 221 is horizontally provided at the bottom of the side wall of the outer barrel body 21. The heating pipe 221 can be connected t...

Embodiment 2

[0039] Such as Figure 5 It is a cross-sectional view of a drying barrel of a seed drying device in Embodiment 2, including a frame 1 and a drying barrel 2 arranged on the frame 1, and the top of the drying barrel 2 is provided with at least two feeding ports 211 , the bottom of the drying barrel 2 is provided with a discharge pipe 26, the discharge pipe 26 is provided with a valve 261, the drying barrel 2 includes an outer barrel body 21 and an inner barrel body 22, the top of the inner barrel body 22 is connected with the top of the outer barrel body 21, and the inner barrel Body 22 is the same as the axis line of outer barrel body 21, discharge pipe 26 runs through inner barrel body 22 and outer barrel body 21, a heating pipe 221 is arranged horizontally at the bottom of the side wall of outer barrel body 21, and a blower 24 is arranged at the bottom of outer barrel body 21, The air outlet of blower 24 faces the inside of outer barrel body 21, and the top of inner barrel bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com