Gas drying system and method

A gas drying and drying technology, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of easy retention, decreased drying efficiency of dryers, and waste of drying gas, etc., to achieve increased efficiency, convenient operation, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

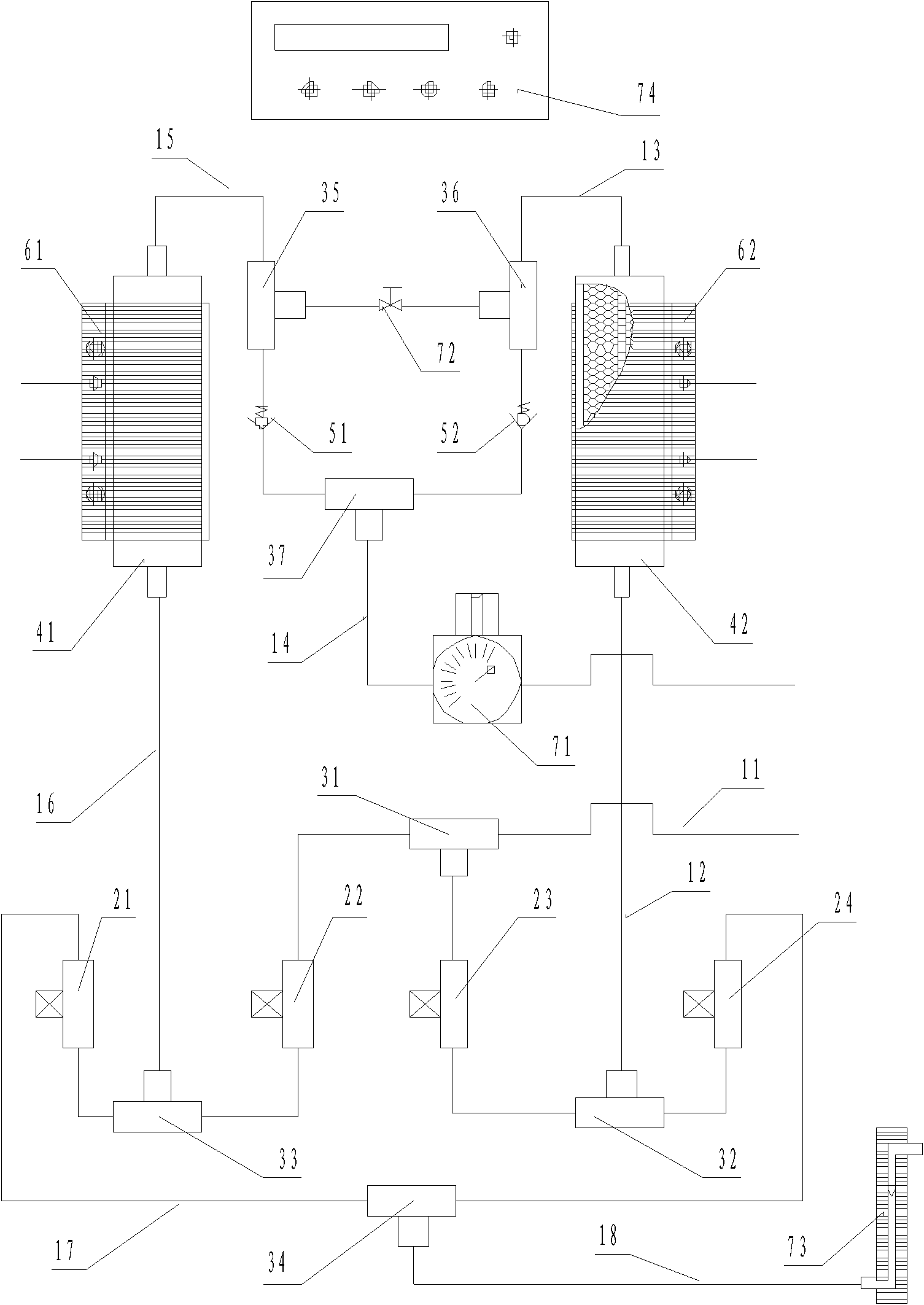

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] The present invention adopts the method of combining the two principles of pressure swing adsorption and temperature swing adsorption, that is, the desorption efficiency of the moisture of the adsorbent is increased by the dry gas after heating, and the drying and drying of the gas are carried out in circulation between two dryers. Activation and regeneration of the adsorbent.

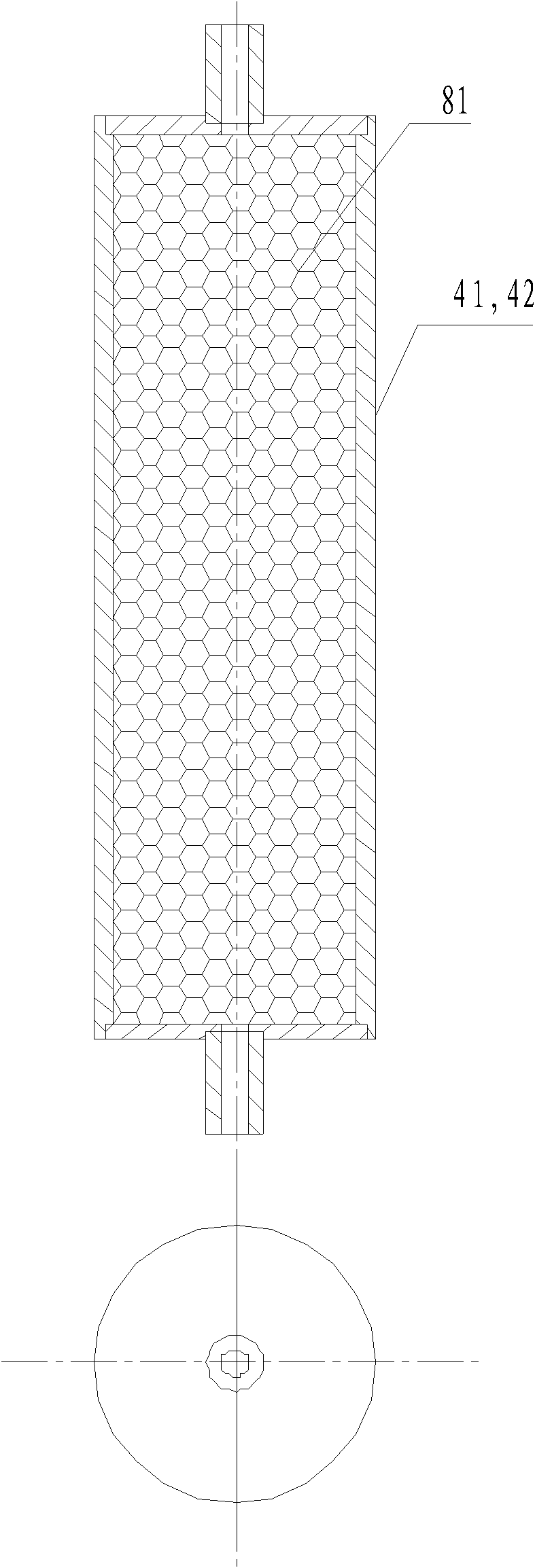

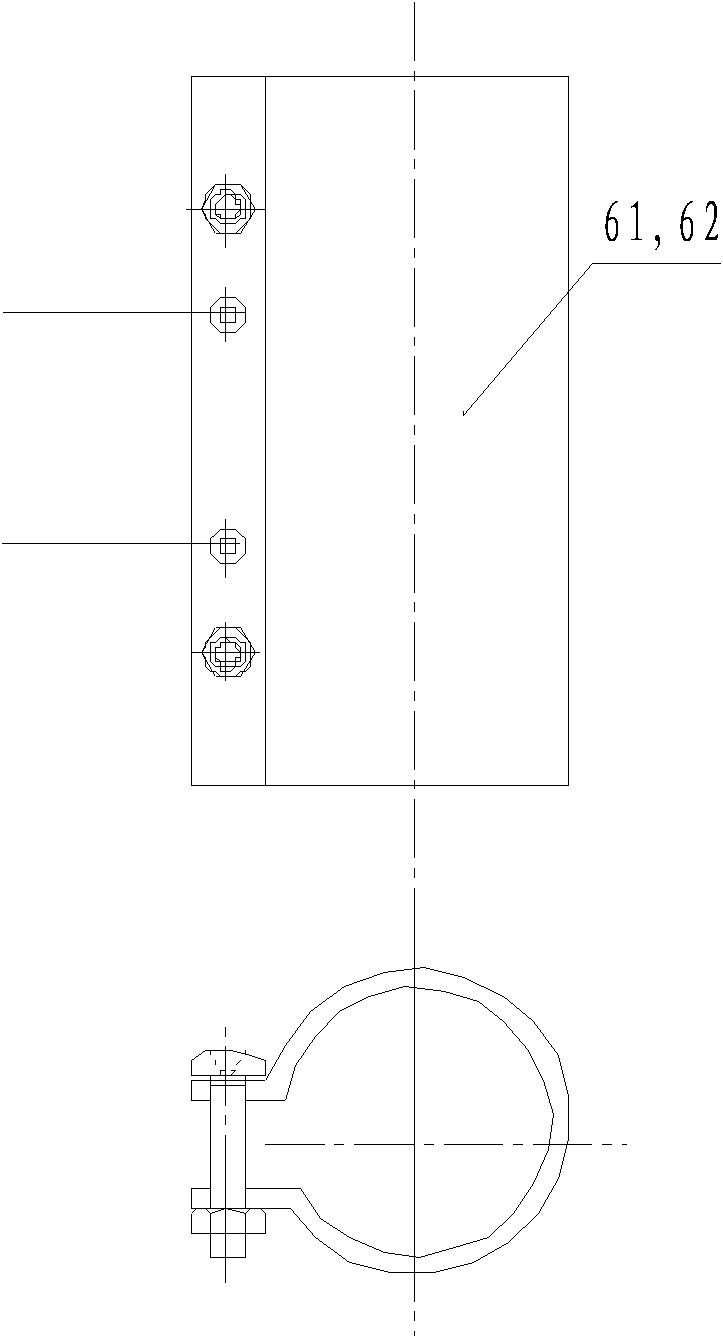

[0044] The gas drying system provided by the present invention includes two dryers (the first dryer and the second dryer), electromagnetic valves connected between the lower interface of the two dryers, the gas inlet and the moisture exhaust outlet respectively, The one-way check valve between the upper interface of the two dryers and the gas outlet is respectively connected with the solenoid valve to control the time controller for opening and closing of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com