A temperature-controllable pressure-controlled oil-gas-water-solid multiphase pipeline simulation experiment device

A technology for simulating experimental devices and transportation pipelines, which is applied in the field of simulating experimental devices for oil, gas, water and solid multiphase transportation pipelines with controllable temperature and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

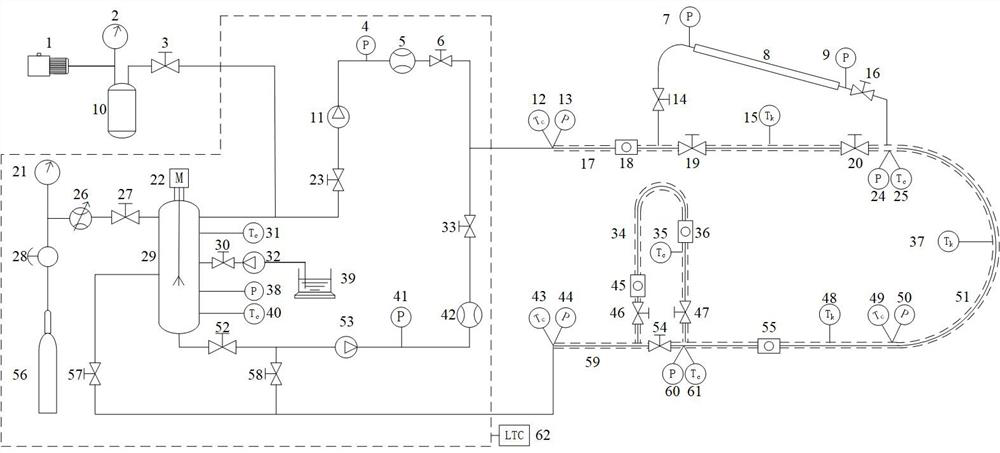

[0021] The first step: close the eighth valve 27 and the ninth valve 30, open the reaction kettle 29 and all valves on the connecting pipeline of the test pipeline, and open the first valve 3;

[0022] Second step: turn on the vacuum pump 1 to evacuate the reaction kettle 29 and the test pipeline, and measure the vacuum pressure with the vacuum gauge 3;

[0023] The third step: when the reading of the vacuum gauge 3 is stable for a period of time, close the first valve 3, and then shut down the vacuum pump 1;

[0024] Step 4: open all valves on the test pipeline, and inject tap water into the test loop through the ninth valve 30;

[0025] Step 5: After the water injection is completed, stop the liquid filling pump 32 and close the ninth valve 30 of the water injection port;

[0026] Step 6: Open the eighth valve 27, inject the experimental gas in the high-pressure gas cylinder 56 into the reaction kettle 29, and the amount of feed is controlled by the gas mass flow controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com