Disposable Downhole Tool

a tool and tool body technology, applied in the direction of fluid removal, borehole/well accessories, construction, etc., can solve the problems of increasing production, increasing equipment and time, and greater control of fracturing the entire length of the lateral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

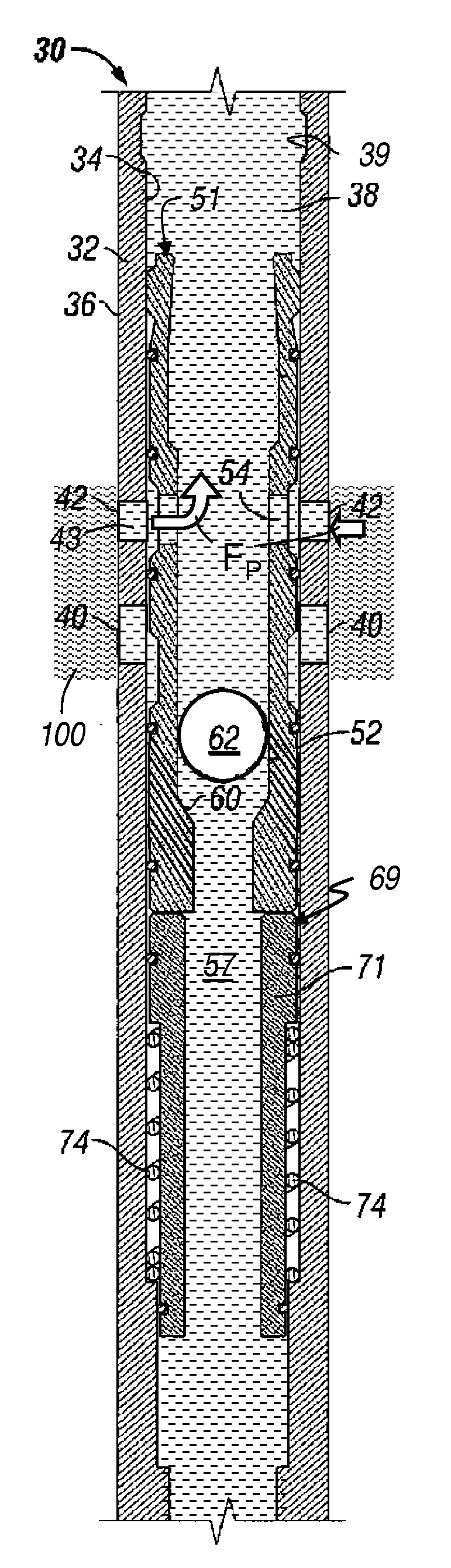

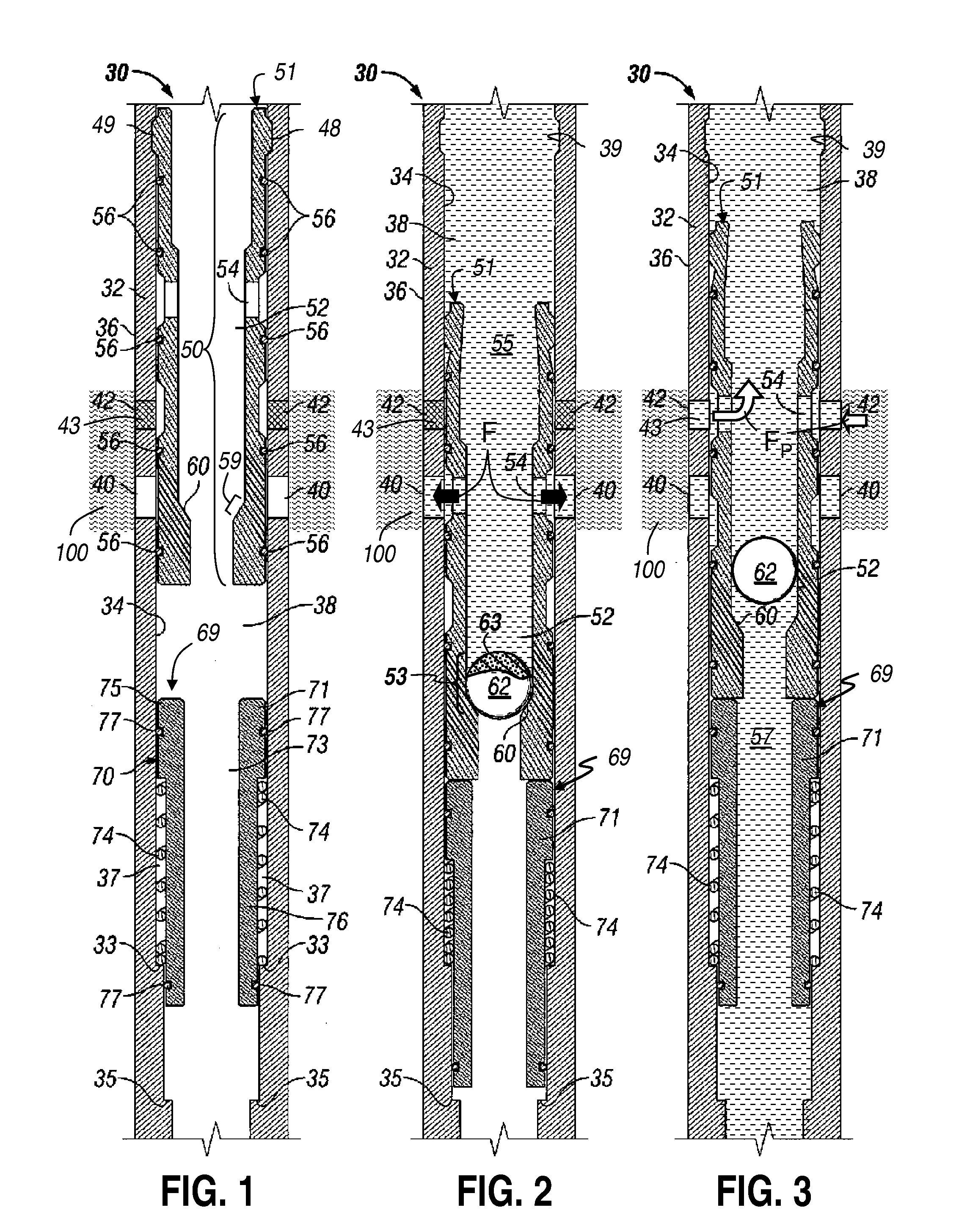

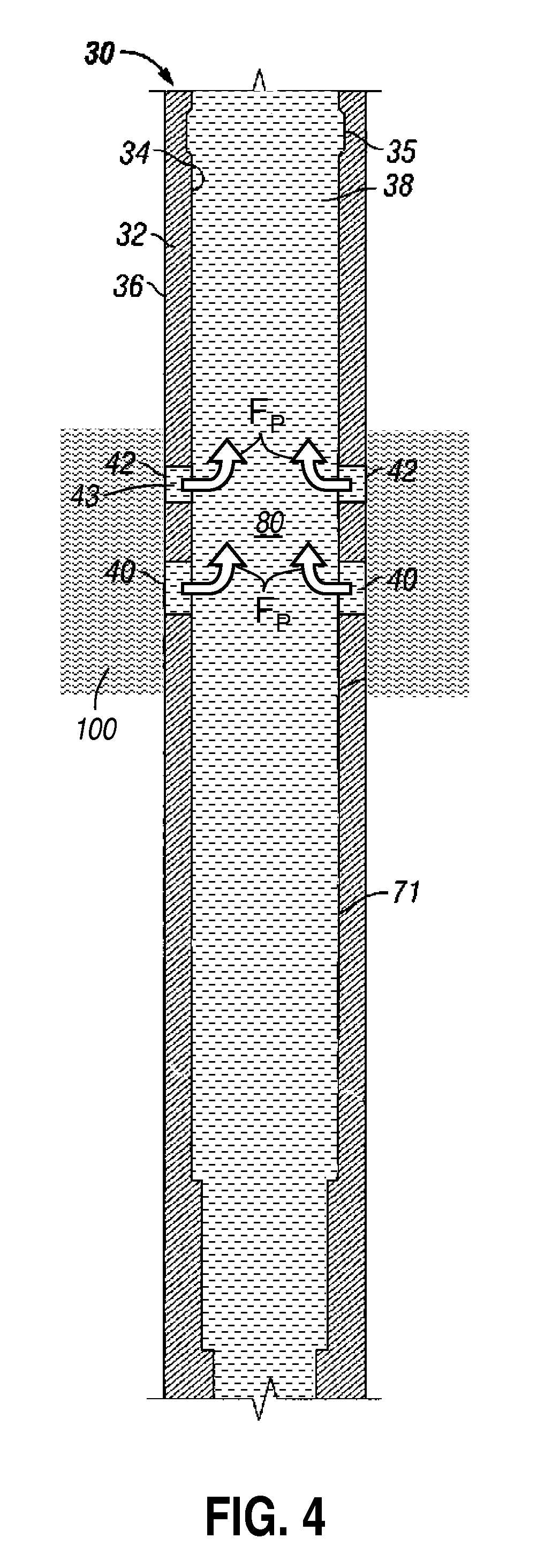

[0015]Referring to FIGS. 1-4, an exemplary embodiment of a downhole frac tool 30 is disclosed. The frac tool 30 includes an outer housing 32 that includes an inner wall surface 34 defining a bore 38. Frac tool 30 also includes a valve structure 50 disposed within the bore 38. The valve structure 50 is used to provide a disposable valve 53 that is configured to selectively control the flow (F) of a frac fluid 55 within frac tool 30 as shown in FIG. 2, particularly to selectively direct flow F of frac fluid 55 from the frac tool 30 into a surrounding earth formation in conjunction with frac operations. Valve structure 50 includes a disposable plug seat 59 for seating a disposable plug 62 in sealing engagement with therewith. Disposable plug seat 59 may include all manner of suitable disposable plug seats 59 for seating various forms disposable plugs 62, such as disposable balls 63, to form various disposable plug valves 53. In one exemplary embodiment, disposable plug seat 59 may incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com