Gasproof damper valve

A plug-in valve, plug-in technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of the valve losing the function of closing, the plug-in is not closed properly, the sealing performance is deteriorated, etc., to increase the lubrication performance, The effect of extended service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

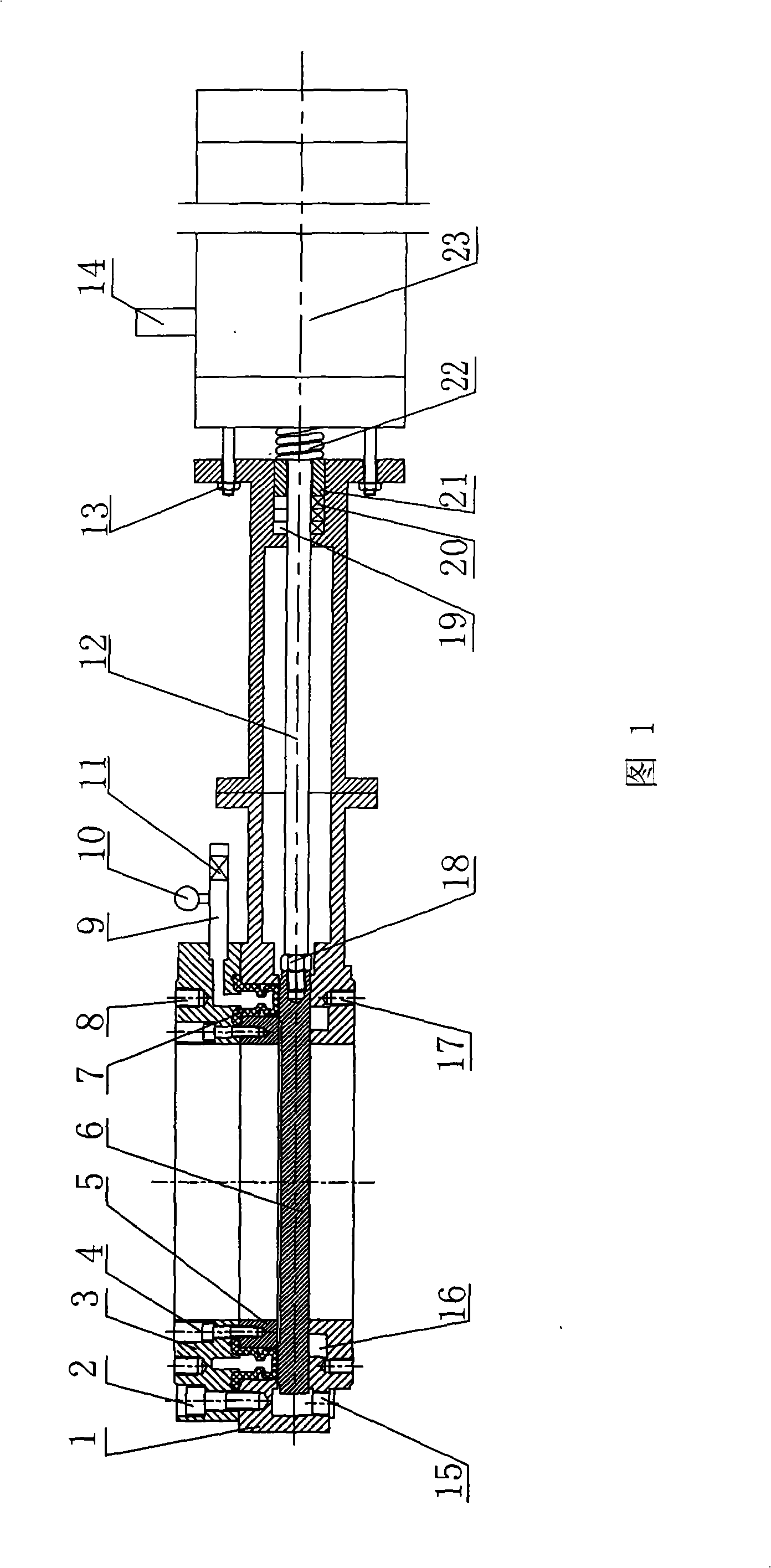

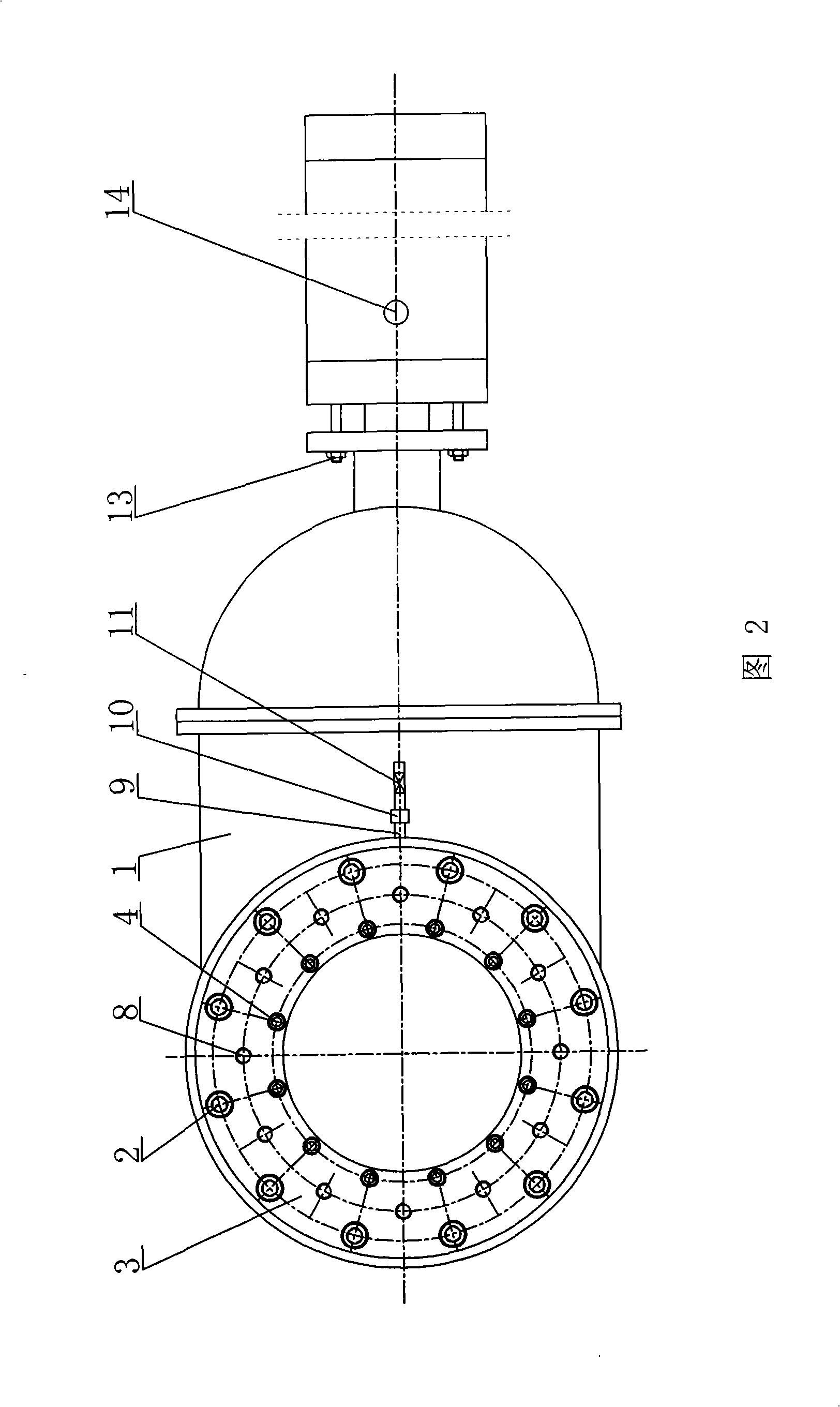

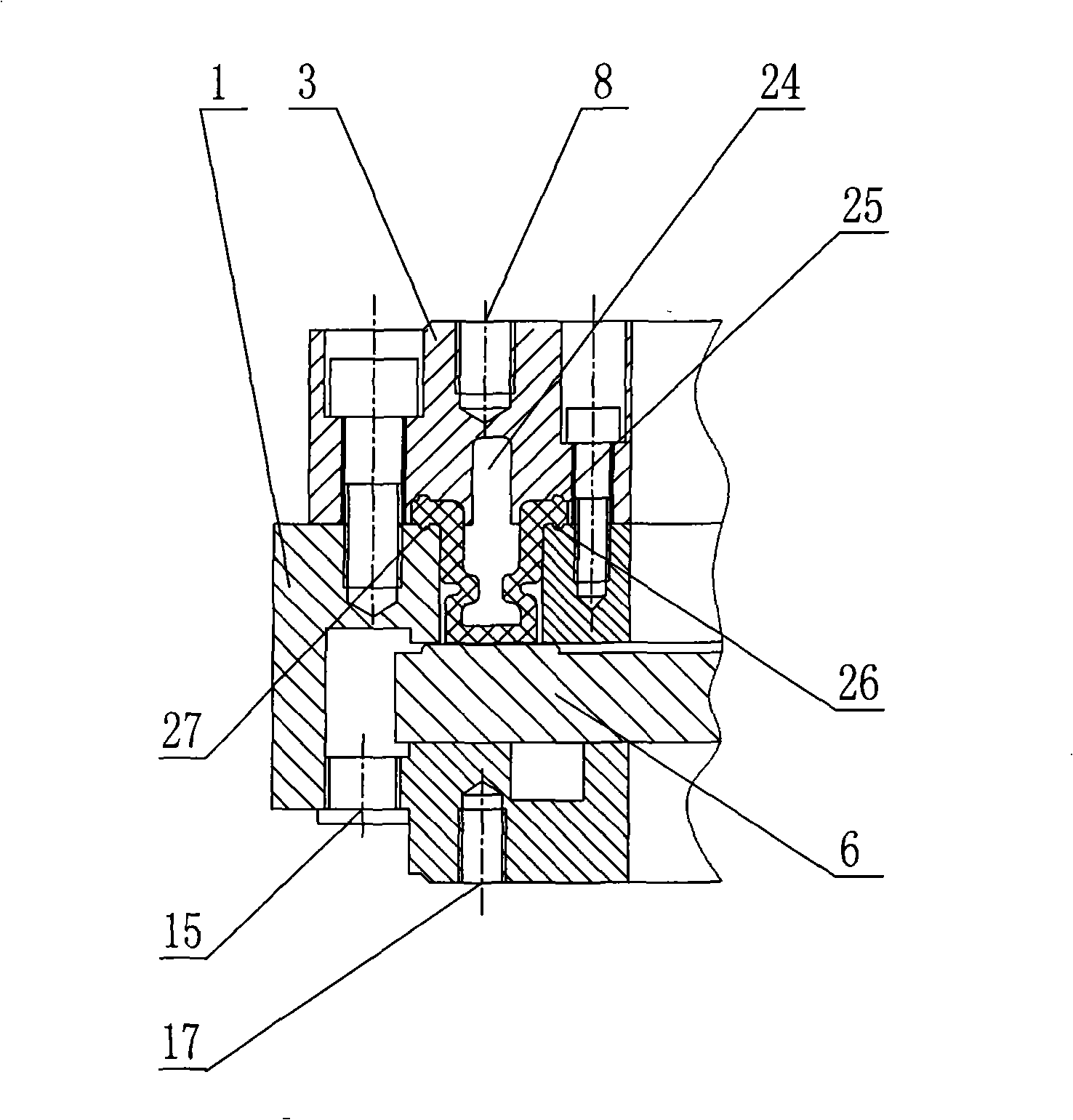

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the examples given in the accompanying drawings.

[0025] As shown in Figures 1, 2, and 3, an airtight gate valve according to the present invention includes a valve seat 1, an upper valve cover 3, an upper valve cover pressing bolt 2, a gate plate 6, and a gate plate lock nut 18 , flashboard push rod 12, flashboard push rod driving device 23, characterized in that a special-shaped rubber sealing ring 7 with a cavity is provided between the upper valve cover 3 and the flashing plate 6, and the special-shaped rubber sealing ring The outer side of 7 is in contact with the valve seat 1, the inner side of the special-shaped rubber sealing ring 7 is in contact with the sealing ring pressure ring 5, and the sealing ring pressure ring 5 is in contact with the upper valve cover 3 through the pressure ring bolt 4 Connect, the cavity of this special-shaped rubber sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com