Method and device for measuring dynamic contact heat exchange coefficient of high-temperature solid interface

A technology of heat transfer coefficient and dynamic contact, which is applied in the measurement of solid dynamic contact heat transfer coefficient, the measurement method and measurement device of high temperature solid interface dynamic contact heat transfer coefficient, can solve the problems of lack of data reporting, etc., and achieve rapid and efficient heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

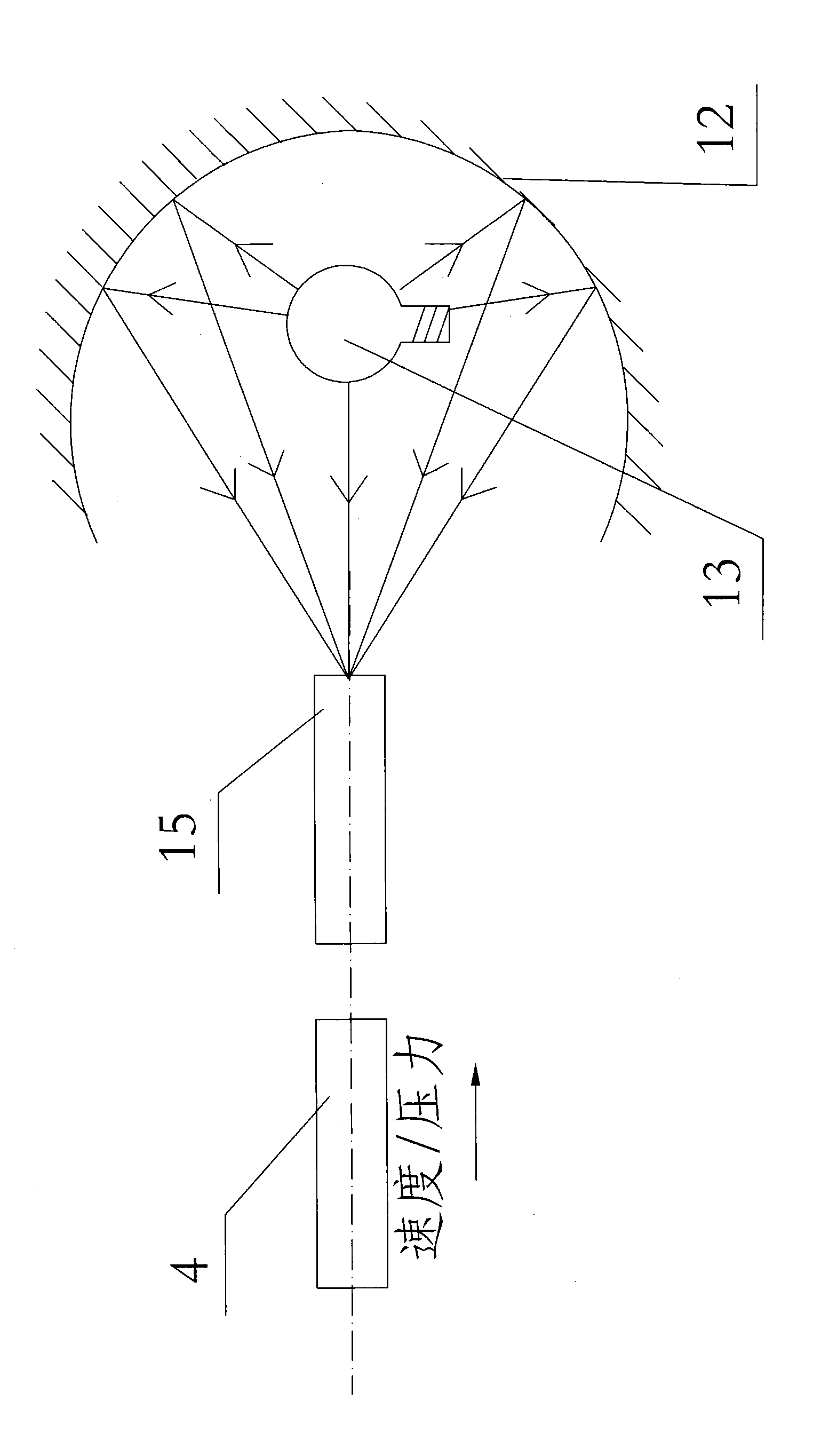

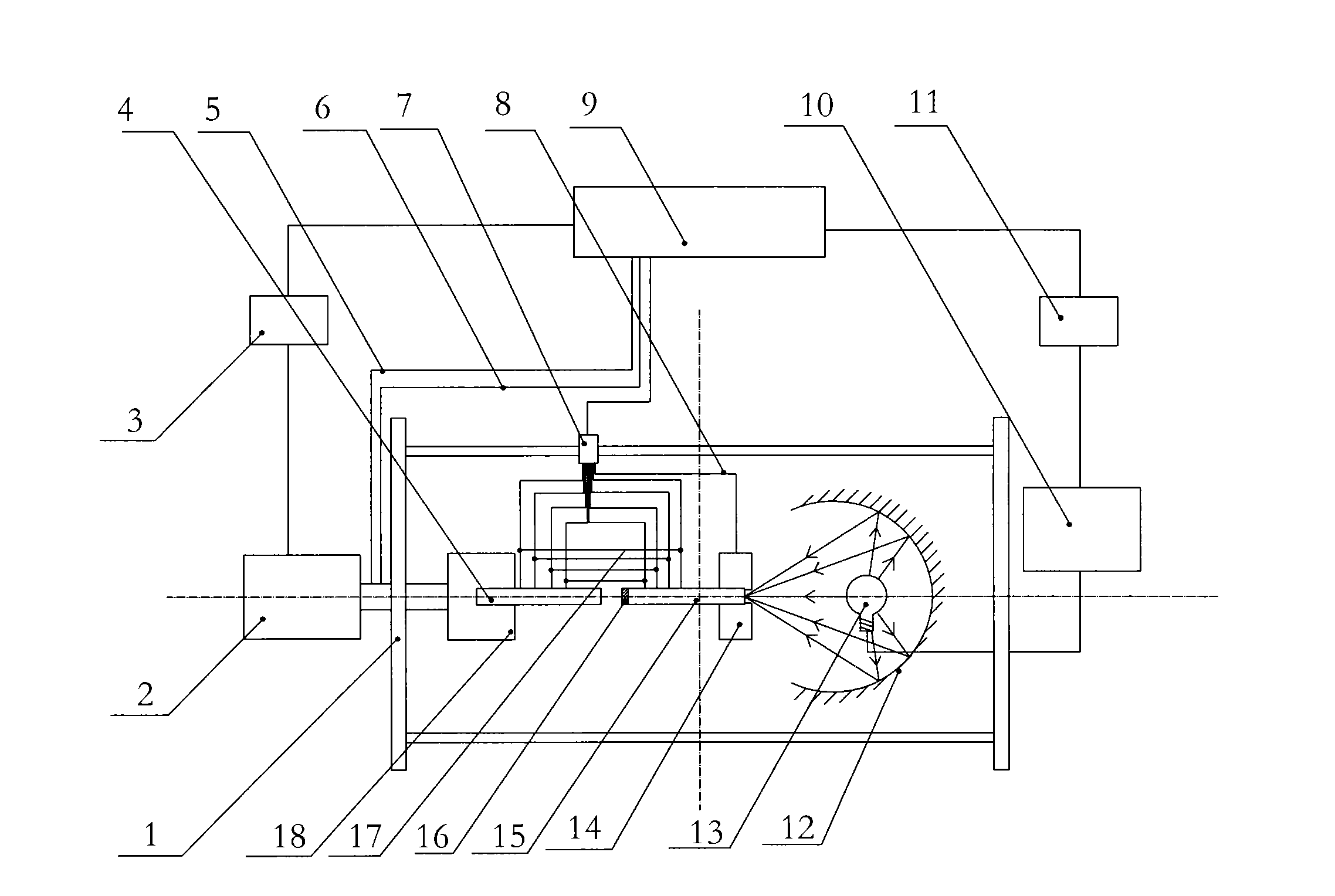

[0034] Combine below figure 1 with image 3 This embodiment will be specifically described.

[0035] The measuring device of the present invention consists of a vacuum chamber 1, a hydraulic cylinder 2, a hydraulic control relay 3, a cold end sample 4, a speed sensor 5, a force sensor 6, a sealed manifold 7, a hot end electric couple 8, an industrial computer 9, and a heating power supply 10. Heating control relay 11, condenser reflector 12, xenon lamp 13, fixed chuck 14, hot end sample 15, lubricant 16, temperature measuring thermocouple (eight groups) 17 and moving chuck 18. Among them: the vacuum chamber 1 can achieve a certain degree of vacuum through an external vacuum device to reduce the influence of the sample oxidation at high temperature on the experimental results; the vacuum chamber 1 is covered with anti-radiation materials such as aluminum foil or heat reflective film The inner wall is used to reduce the thermal radiation influence of the sample; the hydraulic cylin...

Embodiment 2

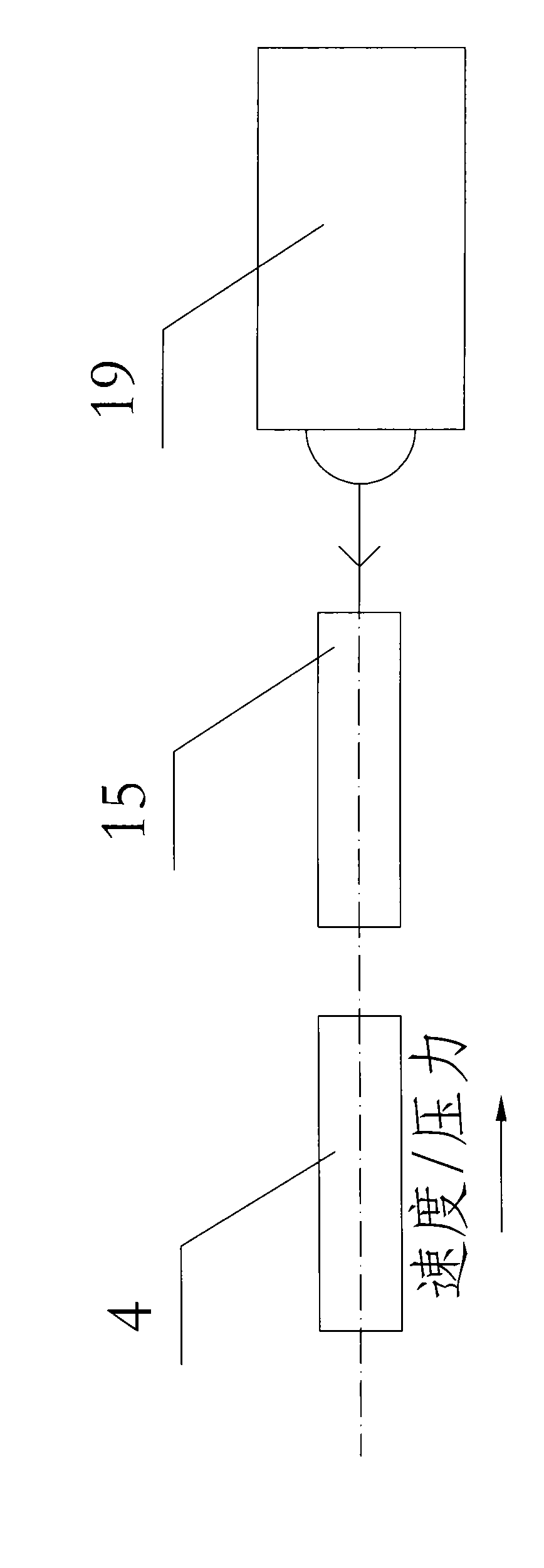

[0047] Combine below figure 2 with Figure 4 This embodiment will be specifically described.

[0048] The measuring device of the present invention consists of a vacuum chamber 1, a hydraulic cylinder 2, a hydraulic control relay 3, a cold end sample 4, a speed sensor 5, a force sensor 6, a sealed manifold 7, a hot end electric couple 8, an industrial computer 9, and a heating power supply 10. Heating control relay 11, laser heater 19, fixed chuck 14, hot end sample 15, lubricant 16, temperature measuring thermocouple (eight groups) 17 and moving chuck 18. Among them: vacuum chamber 1 can achieve a certain degree of vacuum through an external vacuum device to reduce the influence of sample oxidation at high temperature on the experimental results; vacuum chamber 1 has anti-radiation materials such as aluminum foil or heat reflective film covering the inner wall of the box , In order to reduce the thermal radiation influence of the sample; the hydraulic cylinder 2 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com