Non-contact process kit

A kit and coupling technology, applied in the field of non-contact processing kits, can solve problems such as temperature changes of the shielding ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

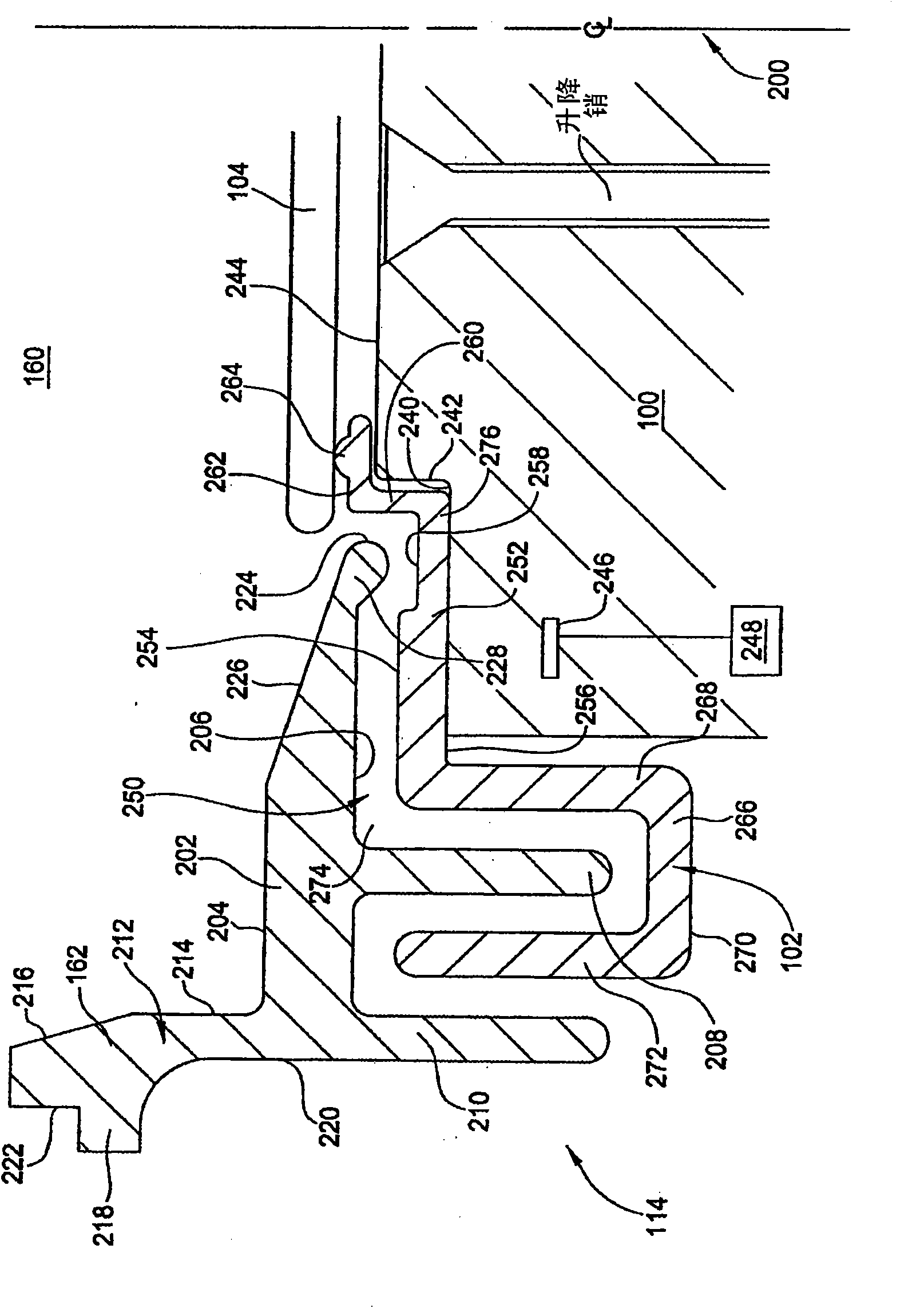

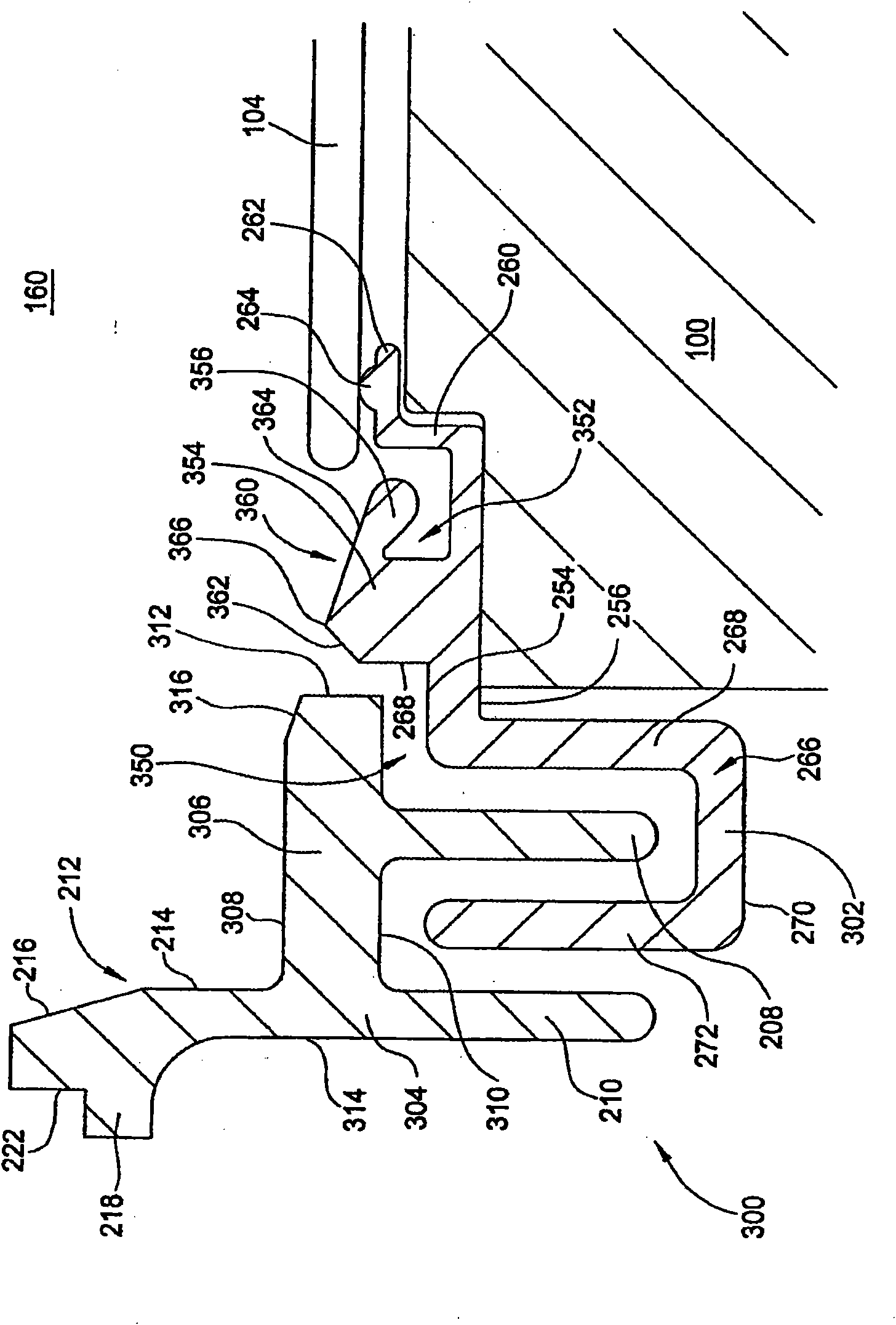

[0019] The present invention generally provides a processing kit for a physical vapor deposition (PVD) processing chamber. Advantageously, the processing kit is less prone to specific contamination, thereby promoting processing uniformity and reproducibility and a longer processing kit life cycle.

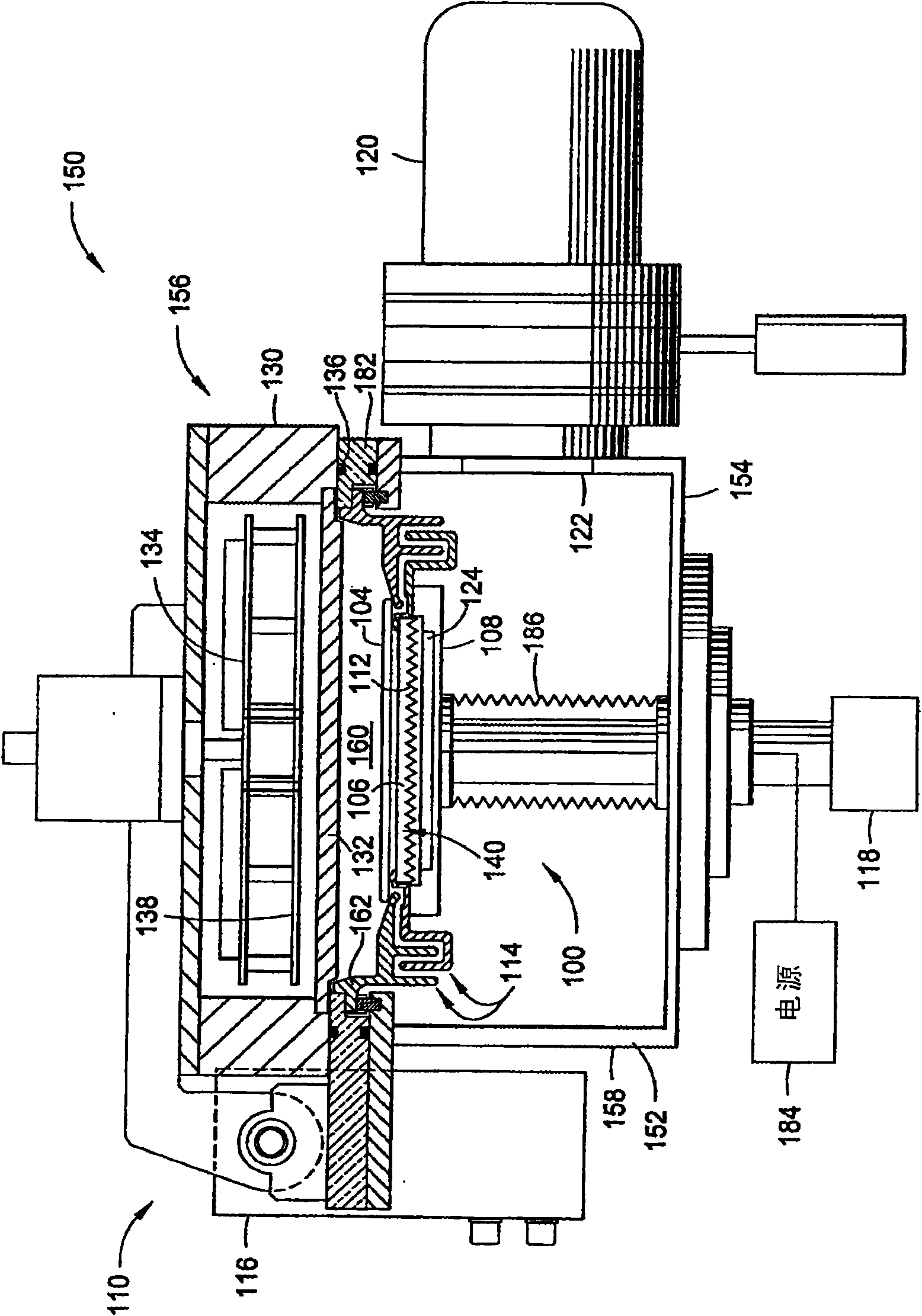

[0020] figure 1 An exemplary semiconductor processing chamber 150 having an embodiment of the processing kit 114 is depicted. The processing suite 114 includes an intersecting deposition ring 102 and a grounded shield 162 . An example of a processing chamber that may benefit from one of the present inventions is the IMPVECTRA available from Applied Materials, Inc., Santa Clara, California. TM PVD treatment chamber. However, it should be understood that other process chambers from other manufacturers may also benefit from the present invention.

[0021] Exemplary processing chamber 150 includes a processing chamber body 152 having a bottom 154 , a lid assembly 156 and a number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com