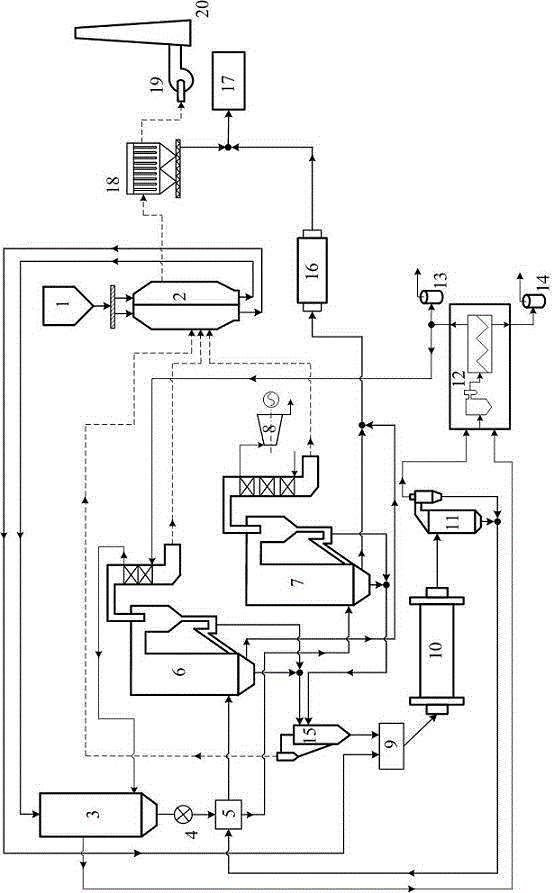

Oil shale gas-solid heat carrier dry distillation and semicoke combustion electricity generation integral process

A heat-fixing carrier and oil shale gas technology, which is applied in the direction of indirect heating dry distillation, direct heating dry distillation, petroleum industry, etc., can solve the problem of long dry distillation time, no consideration of using circulating fluidized bed boiler flue gas to dry wet oil shale, The problem of high crushing energy consumption, etc., to achieve the effect of compact and reasonable process technology structure, improve operation coordination, and improve thermal economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below using the accompanying drawings and examples.

[0023] refer to figure 1, the oil shale gas solid heat carrier dry distillation and semi-coke combustion power generation integration process of the present invention, the oil shale crushed to ≤75mm is stored in the raw material bin 1 and screened, and the small particle shale with a particle size of <15mm and 15-75mm large-grained shale into the left chamber and right chamber of medium-temperature gas indirect or direct heat exchange drying heater 2 respectively, the heating temperature is 50-150°C, and the dried 15-75mm large-grained shale As carbonization raw material, send it to the high-temperature gas indirect carbonization reactor 3 and conduct carbonization with the high-temperature circulating gas heated to 600-750°C in the semi-coke combustion circulating fluidized bed heating gas furnace 6, and the temperature in the reactor is controlled at 450-550°C; Small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com