Device and method for continuously rectifying 3-chloropropyl triethoxysilane

A chloropropyltriethoxysilane and ethanol rectification technology, which is applied in chemical instruments and methods, fractionation, compounds of elements of Group 4/14 of the periodic table, etc. Changes in temperature and pressure, low operability and other problems, to overcome the difficult control of temperature and pressure, improve equipment productivity, and have a broad market prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

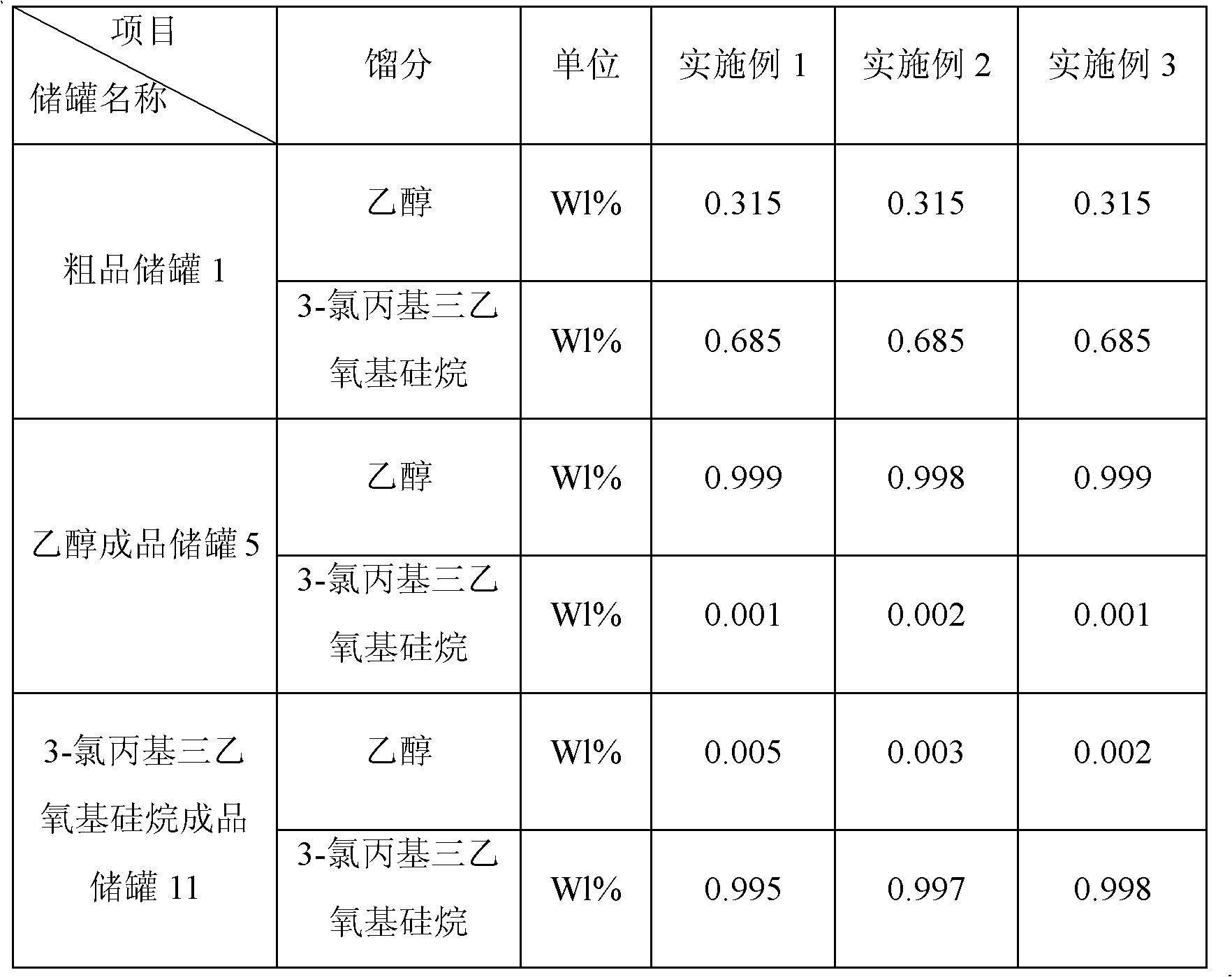

Embodiment 1

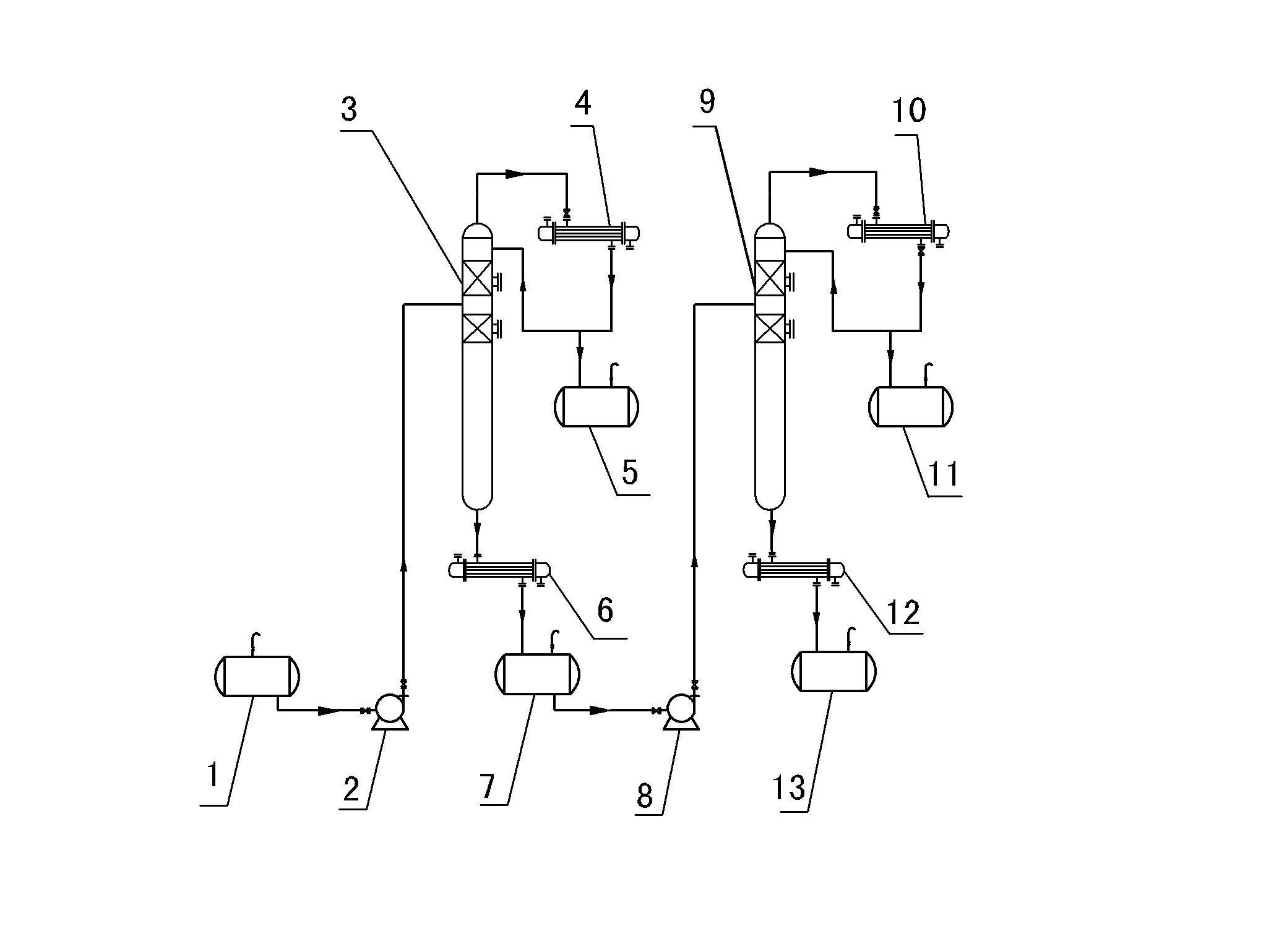

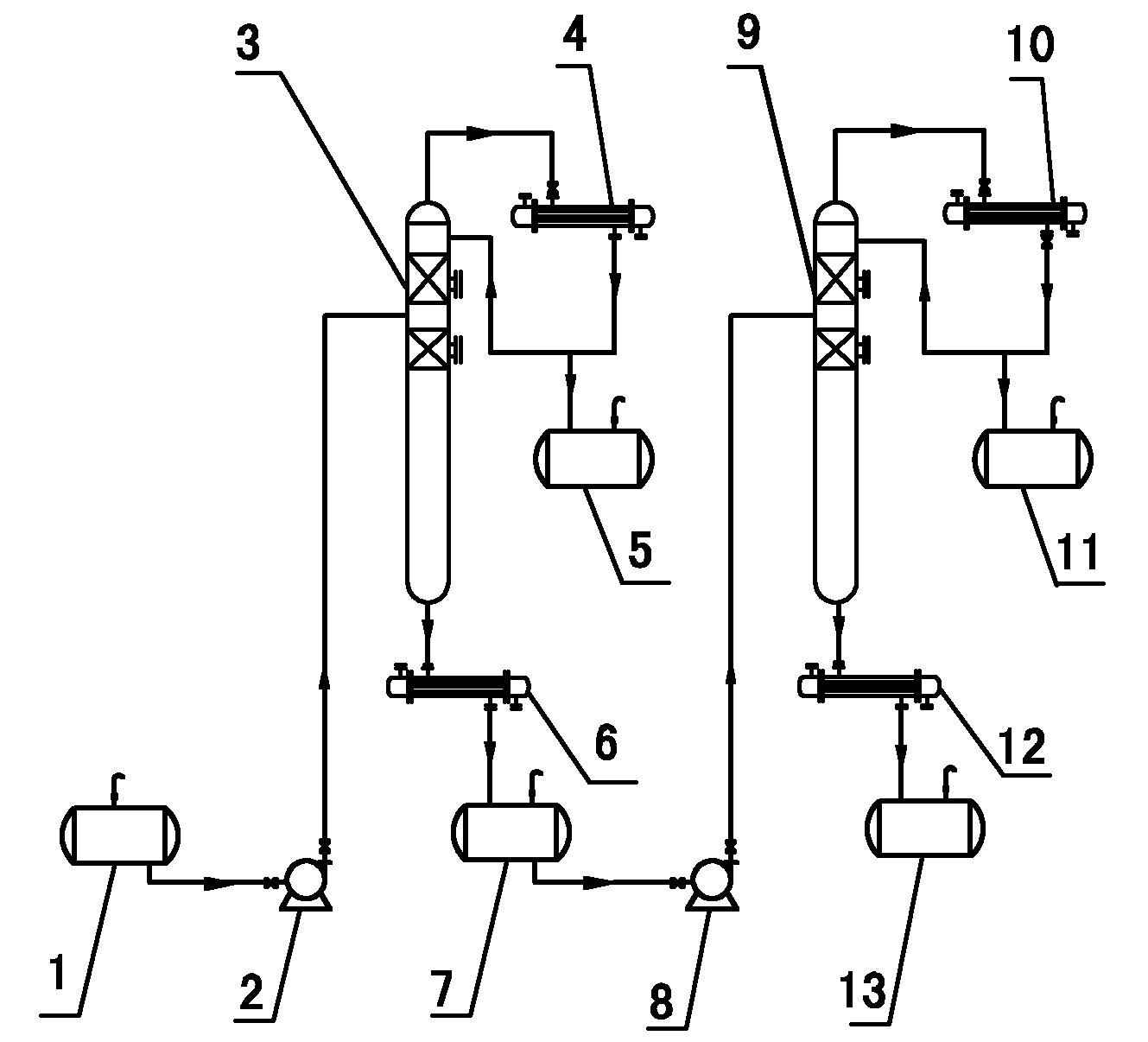

[0017] Attached below figure 1 The device and method for the continuous rectification of 3-chloropropyltriethoxysilane of the present invention are further described:

[0018] refer to figure 1

[0019] The 3-chloropropyltriethoxysilane continuous rectification device consists of two sets of ethanol rectification and separation devices with the same structure and 3-chloropropyltriethoxysilane rectification and separation devices through the delivery pipeline and transfer material The pumps are sequentially connected in series. The inlet of the first rectification tower 3 in the ethanol rectification separation device is connected with the transfer pump 2 and the crude product storage tank 1 through the transfer pipeline, and the top of the first rectification tower 3 is provided with a return pipeline, which is connected to the first condensing tank through the return pipeline. Device 4 is connected with ethanol finished product storage tank 5, and rectification first tower...

Embodiment 2

[0025] The device for the continuous rectification of 3-chloropropyltriethoxysilane in this embodiment is the same as that in Embodiment 1.

[0026] In the present embodiment, its method is as follows:

[0027] Wherein, step a) is identical with embodiment 1;

[0028] b) Control the reflux ratio at the top of the tower to be 5:1, the temperature at the top of the first rectification tower 3 is 78.0°C, the temperature at the bottom of the first rectification tower 3 is 100.0°C, and rectify under normal pressure, when the top of the first rectification tower 3 , after the temperature of the tower still was stable, the first rectifying tower 3 reached the total reflux state, and the continuous feeding in the first rectifying tower 3 was started to separate, and the continuous discharge from the top of the first rectifying tower 3 and the tower still, the first rectifying tower 3. After being condensed by the first condenser 4, the discharge from the top of the tower is stored in...

Embodiment 3

[0031] The device for the continuous rectification of 3-chloropropyltriethoxysilane in this embodiment is the same as that in Embodiment 1.

[0032] In the present embodiment, its method is as follows:

[0033] Wherein, step a) is identical with step a) in embodiment 1;

[0034] b) Control the reflux ratio at the top of the tower to 5:1, the temperature at the top of the first rectification tower 3 is 80.0°C, the temperature at the bottom of the first rectification tower 3 is 110.0°C, and rectify under normal pressure, when the top of the first rectification tower 3 , after the temperature of the tower still was stable, the first rectifying tower 3 reached the total reflux state, and the continuous feeding in the first rectifying tower 3 was started to separate, and the continuous discharge from the top of the first rectifying tower 3 and the tower still, the first rectifying tower 3. After being condensed by the first condenser 4, the discharge from the top of the tower is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com