Solvent distillation recovery device

A distillation recovery, solvent technology, applied in the direction of evaporation, fractionation, chemical instruments and methods, etc., can solve the problems of temperature inconsistency, distillation equipment bursting, waste of energy, etc., achieve uniform heat distribution, prevent corrosion, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following is a further detailed description through specific embodiments:

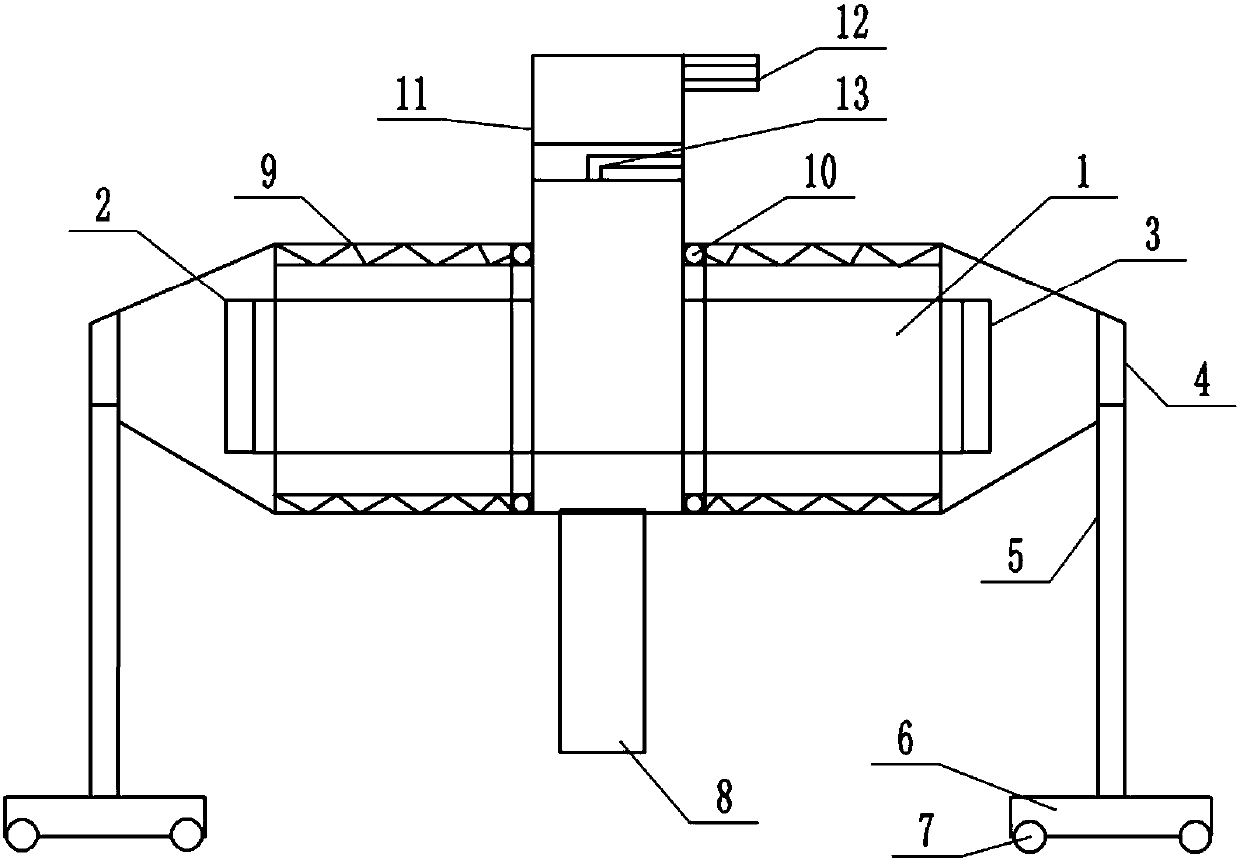

[0013] The reference signs in the drawings include: distillation pipe 1, inlet door 2, outlet door 3, motor 4, support rod 5, base 6, pulley 7, column 8, heating wire 9, ball 10, riser 11, curved Pipe 12, outlet pipe 13.

[0014] The example is basically as attached figure 1 shown:

[0015] In the solvent distillation recovery device, the standpipe 11 and the distillation pipe 1 intersect, the bottom of the standpipe 11 is provided with a supporting column 8, the left side of the distillation pipe 1 is provided with an inlet door 2, and the right side of the distillation pipe 1 is provided with an outlet door 3. Two concentric chutes located outside the distillation tube 1 are symmetrically arranged on the side wall of the standpipe 11. The inside of the chutes is slidably connected with balls 10, and the balls 10 are connected with a spiral heating wire 9, an inlet door 2 and an outlet do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com