A kind of pine resin vacuum distillation device

A distillation device and turpentine technology, which is applied in the field of rosin processing, can solve the problems of low heat utilization rate, slow evaporation of turpentine oil and water, and material accumulation, and achieve the effects of increasing heat exchange area, reducing boiling point, and improving distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

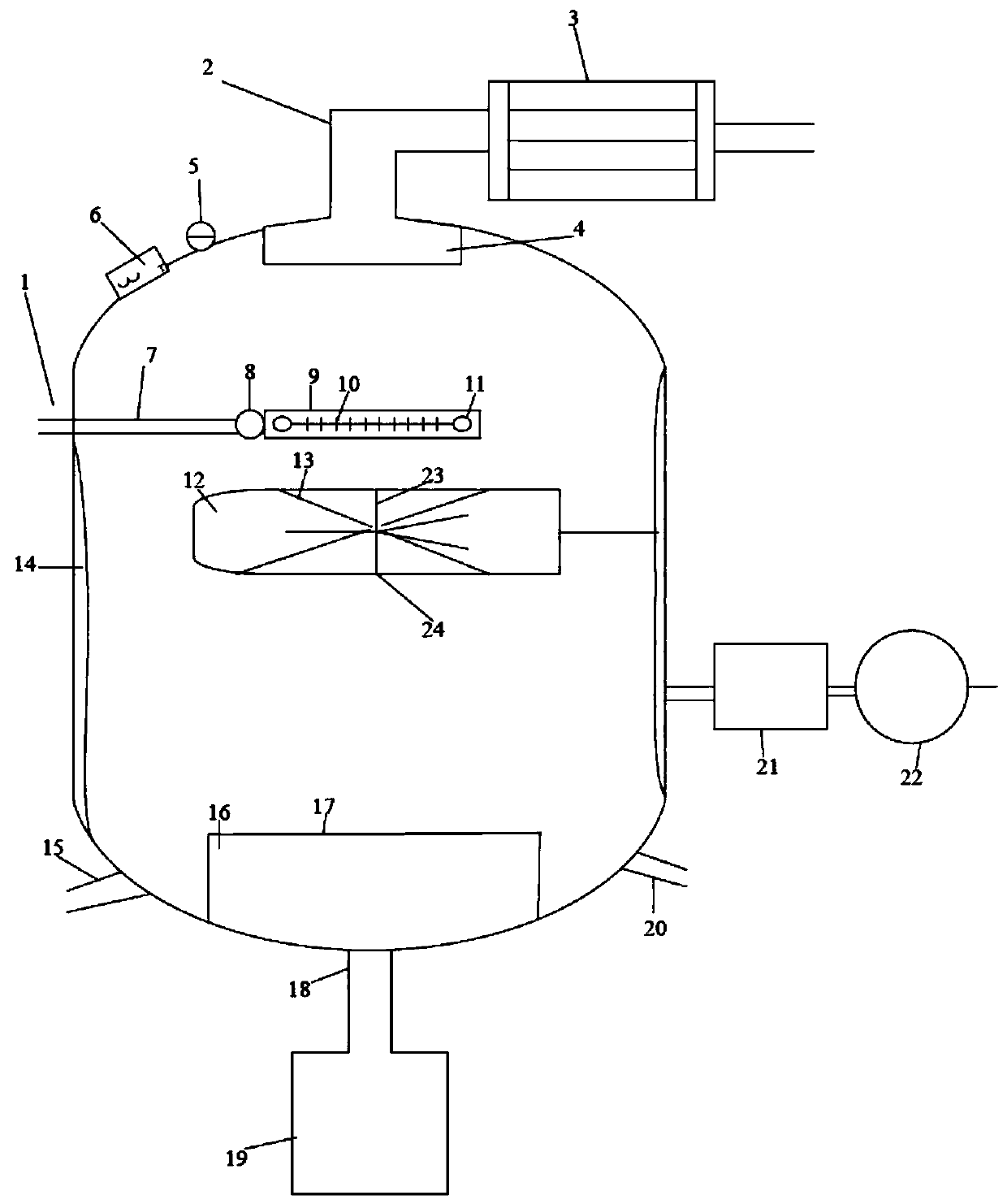

[0024] Below in conjunction with accompanying drawing, rosin processing equipment of the present invention is further described:

[0025] Such as figure 1 Shown, a kind of rosin decompression distillation device comprises still pot main body, condenser and vacuum pumping equipment; Described still pot main body top is provided with mixed steam outlet 2, and bottom is provided with rosin outlet 18, steam inlet 15 and inert gas inlet 20, the interior is provided with a fat liquid channel 1, a stirrer 24 and a rosin collection tank 16; the mixed steam outlet 2 is connected to the condenser 3; the mixed steam outlet 2 is also provided with a steam collector 4, which can quickly collect the steam in the pot steam; the vacuum equipment includes a buffer cylinder 21 and a vacuum pump 22, and the buffer cylinder 21 is connected to the main body of the distillation pot; the inner wall of the main body of the distillation pot is also provided with a No. 1 heating layer 14; the fat liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com