Oil sand dry distilling system

An oil storage system and dry distillation technology, used in special forms of dry distillation, petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of high production cost, low equipment life, large fuel consumption, etc. The effect of fast, continuous dry distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

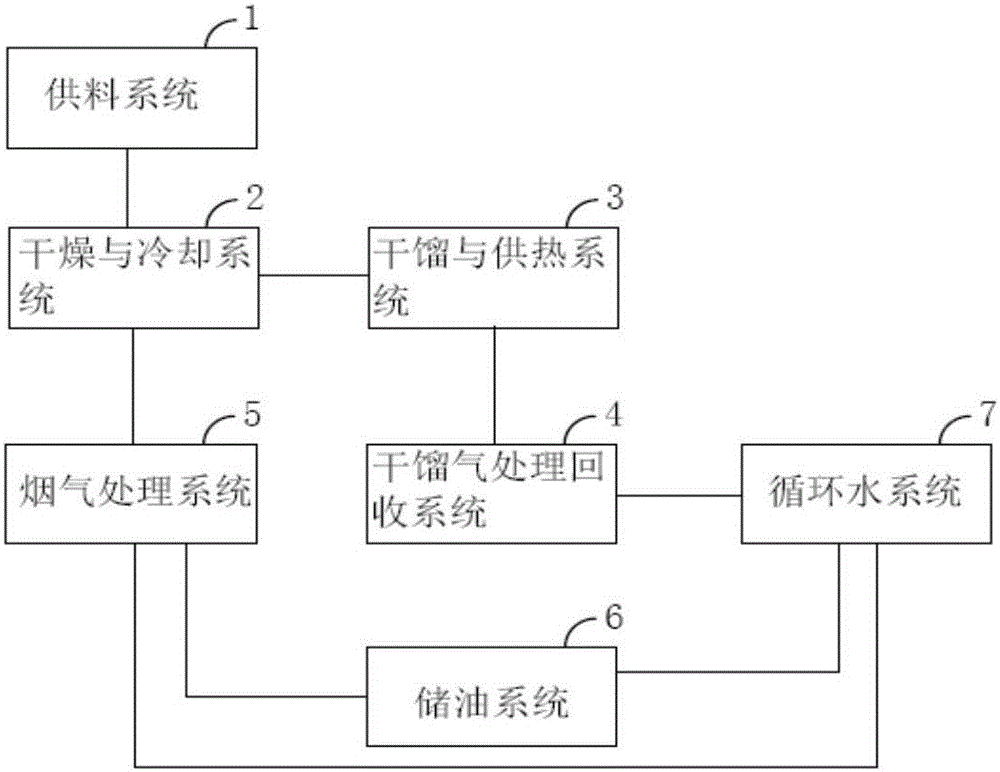

[0052] figure 1 A schematic structural diagram of the oil sands carbonization system provided by the present invention is shown, and for the convenience of description, only the parts related to the present invention are shown in the figure.

[0053] Oil sand retort system includes feeding system 1, drying and cooling system 2, retort and heating system 3, retort gas treatment and recovery system 4, flue gas treatment system 5, oil storage system 6 and circulating water system 7, of which:

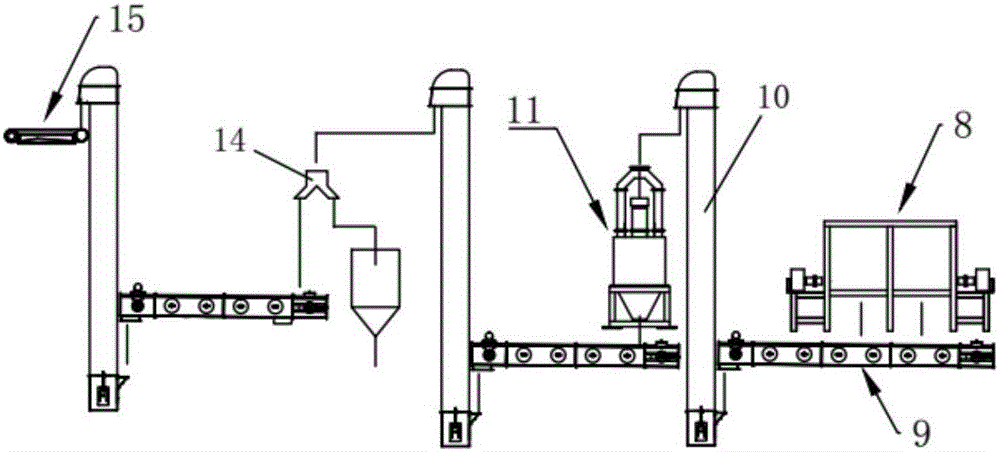

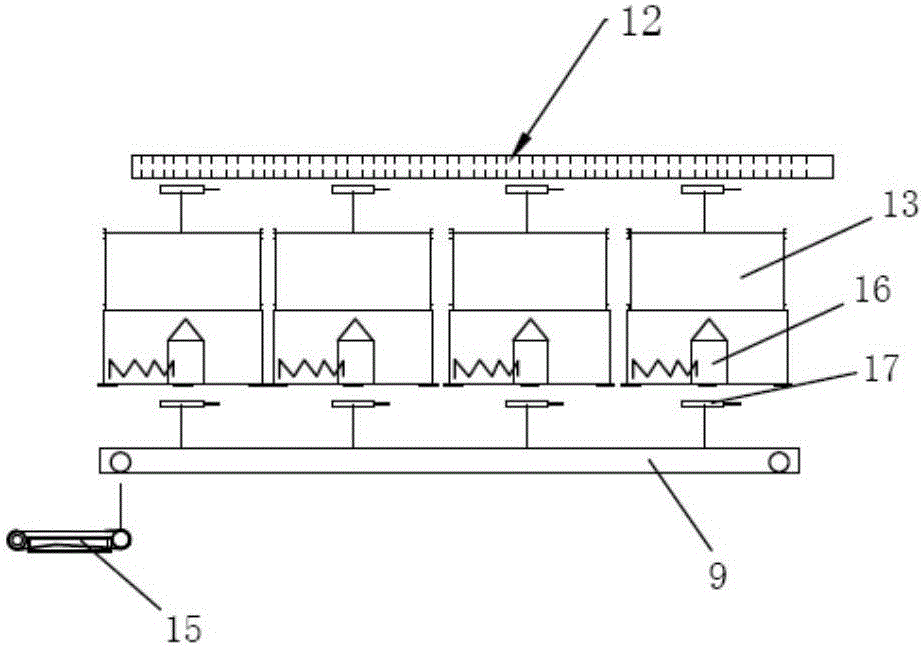

[0054] The feeding system 1 includes a raw material supply device and a raw material storage device. As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com