Energy saving wine brewing device

An energy-saving, distiller's grains technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of low purity of distilled liquor, lower production costs, waste of heat, etc., and achieve the effects of improving distillation efficiency, realizing recycling, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

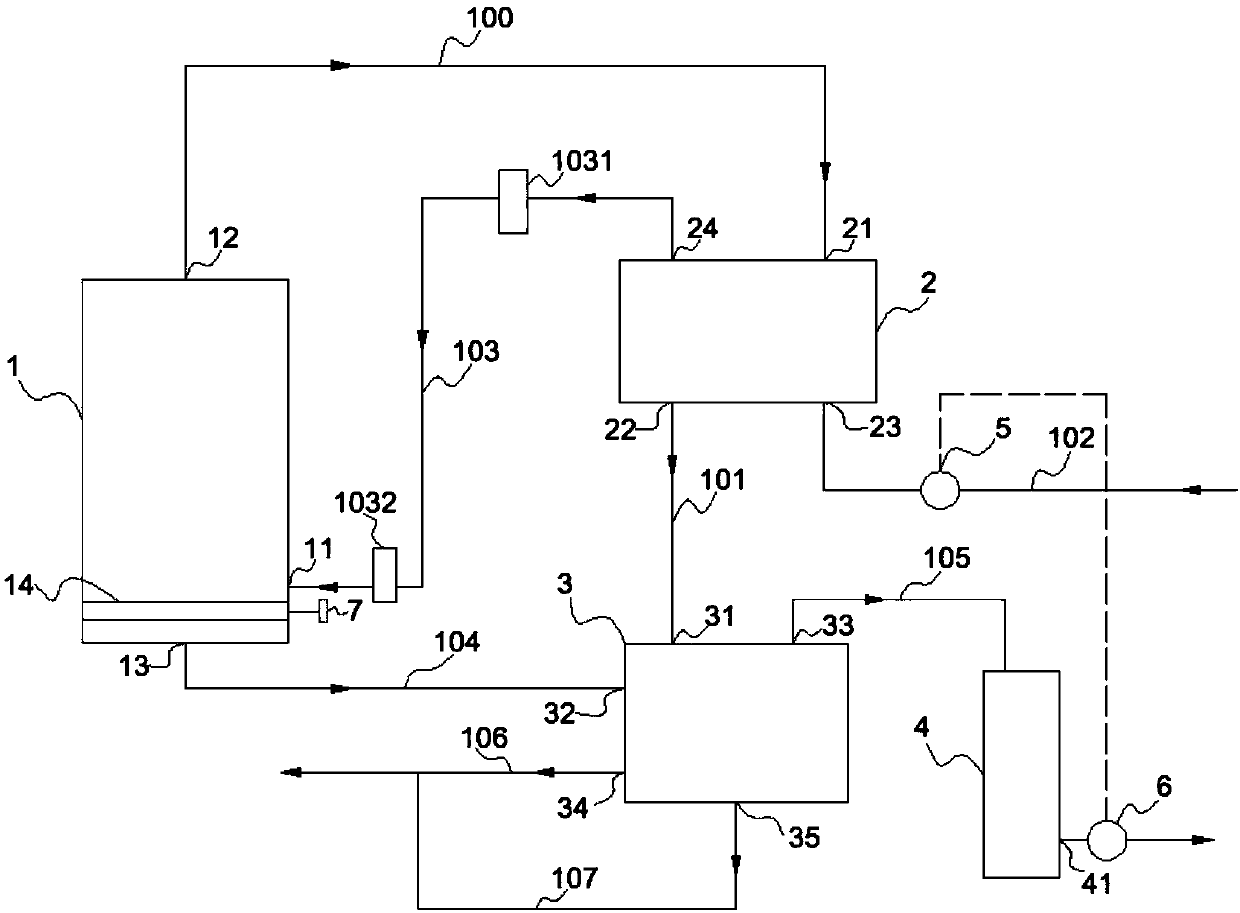

[0024] This embodiment provides an energy-saving brewing device, which not only has a high energy utilization rate, but also produces a high-purity liquid finished wine. For details, please refer to figure 1 The structural schematic diagram of the energy-saving brewing device shown.

[0025] It can be seen from the figure that the energy-saving brewing device includes a distillation tank 1 , a condenser 2 , a secondary evaporator 3 and a cooler 4 . The distillation tank 1 is used to heat the mature distiller's grains to be treated, the condenser 2 is used to condense the wine vapor discharged from the distillation tank 1, and simultaneously heat the mature distiller's grains entering the distillation tank 1, and the secondary evaporator 3 is used to utilize the distillation tank 1 The distillation waste liquid carries out secondary evaporation to the condensed liquid condensed by the condenser 2 to generate secondary wine vapor. Preferably, the secondary evaporator 3 is a fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com