Low-energy-consumption zero-emission evaporated gas treating system of liquefied natural gas (LNG) receiving station

A processing system and receiving station technology, which is applied in the field of low-energy evaporation gas zero-emission processing system of LNG receiving station, can solve problems such as low pressure of LNG storage tanks, difficult operation, and unstable system pressure, so as to avoid waste and ensure safe operation , safety and operability improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

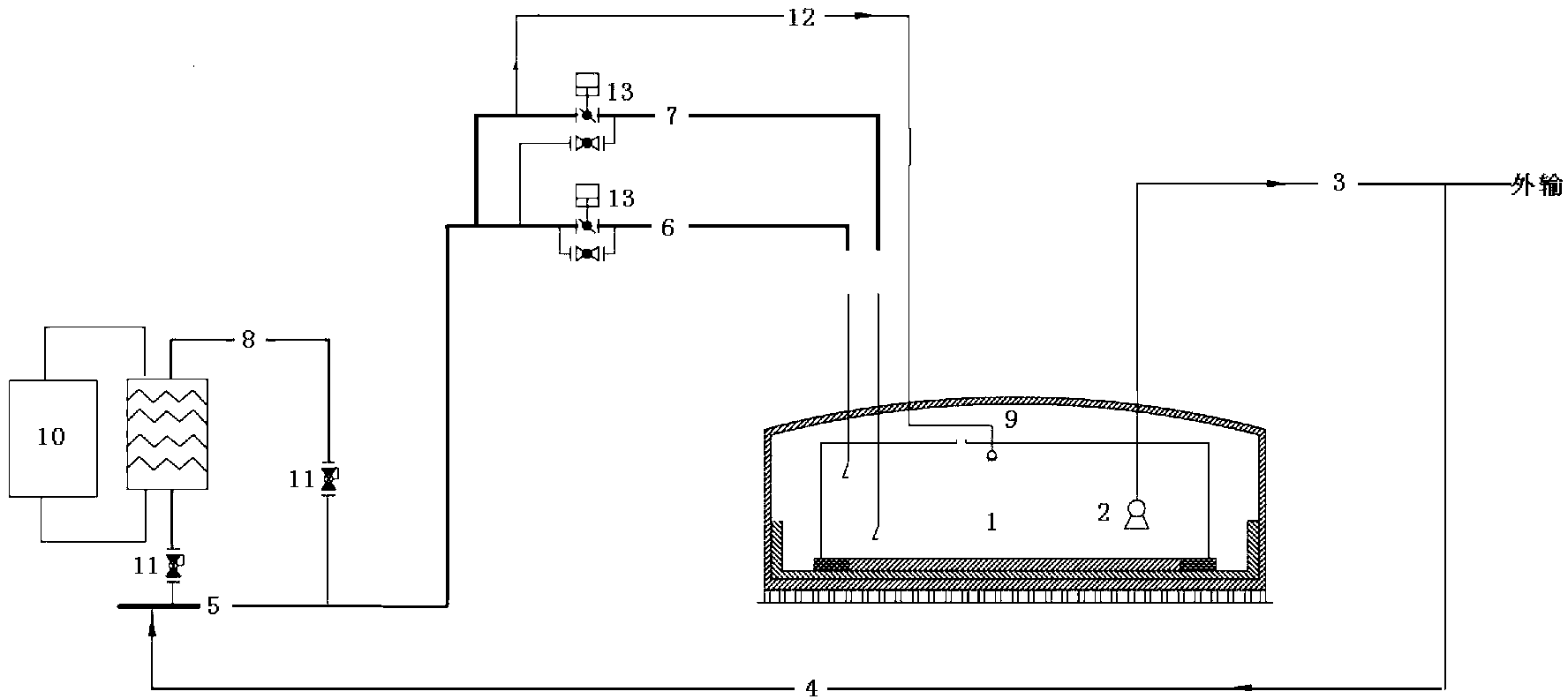

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

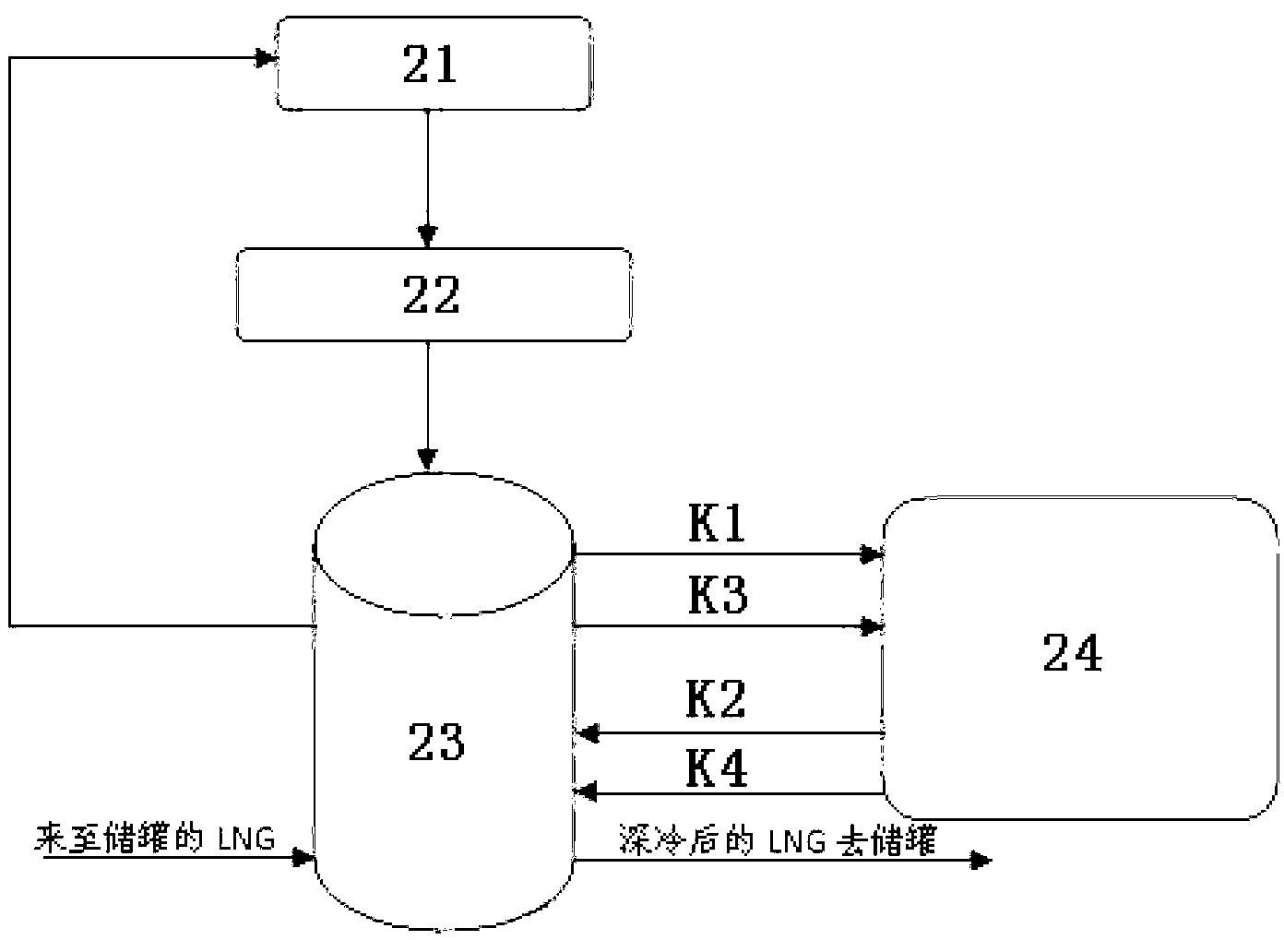

[0012] The present invention mainly utilizes the characteristics that both the normal operation condition of the LNG receiving station and the intermittent zero-transport working condition need to open the cold storage circulation system of the wharf unloading pipeline, and arranges LNG refrigeration on the cold storage circulation pipeline of the existing wharf unloading pipeline of the LNG receiving station. The branch circuit draws LNG from the cold preservation circulation pipeline, further cools it with the help of refrigeration equipment, and sends the cooled LNG back to the original pre-cooling spray system on the top of the LNG storage tank, and then sprays it into the LNG storage tank, thereby Absorb BOG in the tank to realize zero discharge treatment of BOG.

[0013] like figure 1 As shown, the present invention is based on the expansion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com