A system and method for harmless treatment of oily sludge

A technology of harmless treatment and sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

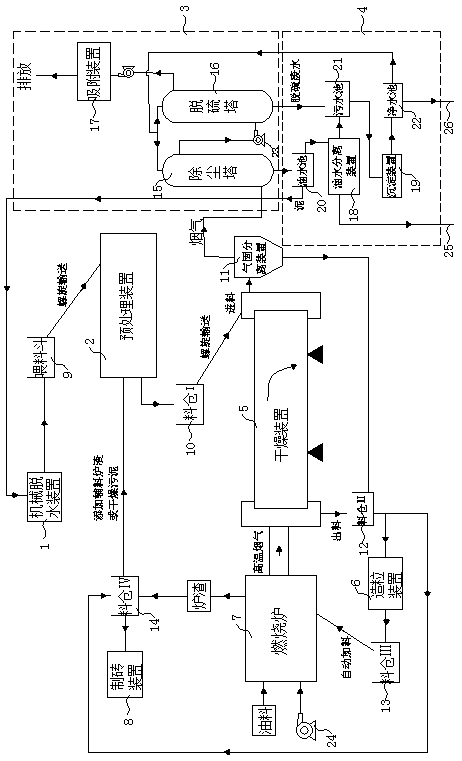

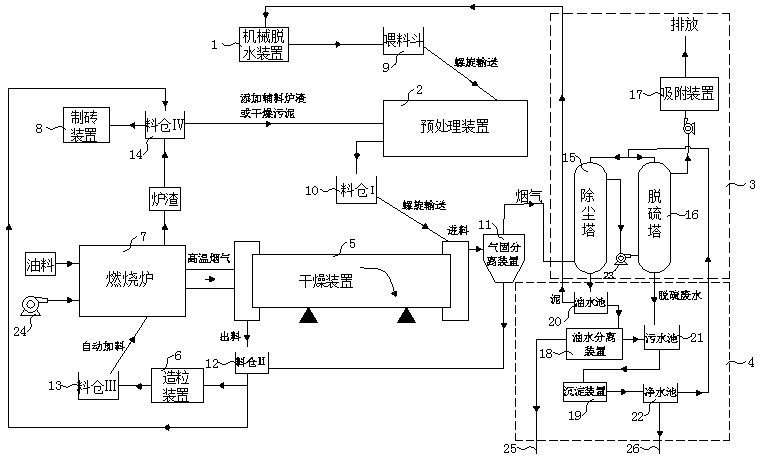

[0022] Such as figure 1 As shown, a kind of oily sludge harmless treatment system of the present invention is composed of mechanical dehydration device 1, pretreatment device 2, gas treatment unit 3, water treatment unit 4, drying device 5, granulation device 6, combustion furnace 7 and a brick-making device 8, characterized in that the output end pipeline of the mechanical dehydration device 1 is connected to the feeding hopper 9, the feeding hopper 9 is connected to the pretreatment device 2 through the spiral conveying pipeline, and the feeding hopper 9 is provided with a horizontal stirring shaft, Prevent oily sludge from adhering to the wall in a large area, and cannot enter the inlet of the screw conveyor; the output end of the pretreatment device 2 is connected to the silo I10, and the silo I10 is connected to the feed port of the drying device 5 through the screw conveying pipeline, and the drying device 5 The air outlet of the gas-solid separation device 11 is connect...

Embodiment 2

[0024] A method for harmless treatment of oily sludge using the above-mentioned device, the specific process flow is as follows:

[0025] a. Pretreatment: Send the oily sludge to the mechanical dehydration device 1 for dehydration, so that the water content of the raw material reaches 80%, and then transport it to the feeding hopper 9, and then transport it to the pretreatment device 2 by a screw conveyor, and at the same time to the pretreatment device Add auxiliary materials (such as sawdust or grass powder for the first start-up, followed by waste residue or dry sludge powder) into the processing device 2, and stir evenly to obtain pretreated raw materials, in which the ratio of dehydrated oily sludge to auxiliary materials is 1:0.1, in this step, the raw materials are dispersed and mixed with loose, porous, small particle size, and low specific heat auxiliary materials to increase the specific area of sludge particles, reduce the viscosity of the material, enhance the flu...

Embodiment 3

[0033] A method for harmless treatment of oily sludge using the above-mentioned device, the specific process flow is as follows:

[0034] a. Pretreatment: Send the oily sludge to the mechanical dehydration device 1 for dehydration, so that the water content of the raw material reaches 70%, and then transport it to the feeding hopper 9, and then transport it to the pretreatment device 2 by a screw conveyor, and at the same time to the pretreatment device Add auxiliary materials (such as sawdust or grass powder for the first start-up, followed by waste residue or dry sludge powder) into the processing device 2, and stir evenly to obtain pretreated raw materials, in which the ratio of dehydrated oily sludge to auxiliary materials is 1:3. In this step, the raw materials are dispersed and mixed with loose, porous, small particle size, and low specific heat auxiliary materials to increase the specific area of sludge particles, reduce the viscosity of the material, enhance the fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com