Waste gas treatment equipment and waste gas treatment system

An exhaust gas treatment device and exhaust gas treatment technology are applied in the direction of swirling devices, devices whose axial direction can be reversed, chemical instruments and methods, etc., which can solve the problems of high cost of waste gas treatment and small amount of waste gas treatment, and achieve The effect of reducing waste gas treatment cost, making full use of energy, and greatly increasing the amount of waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

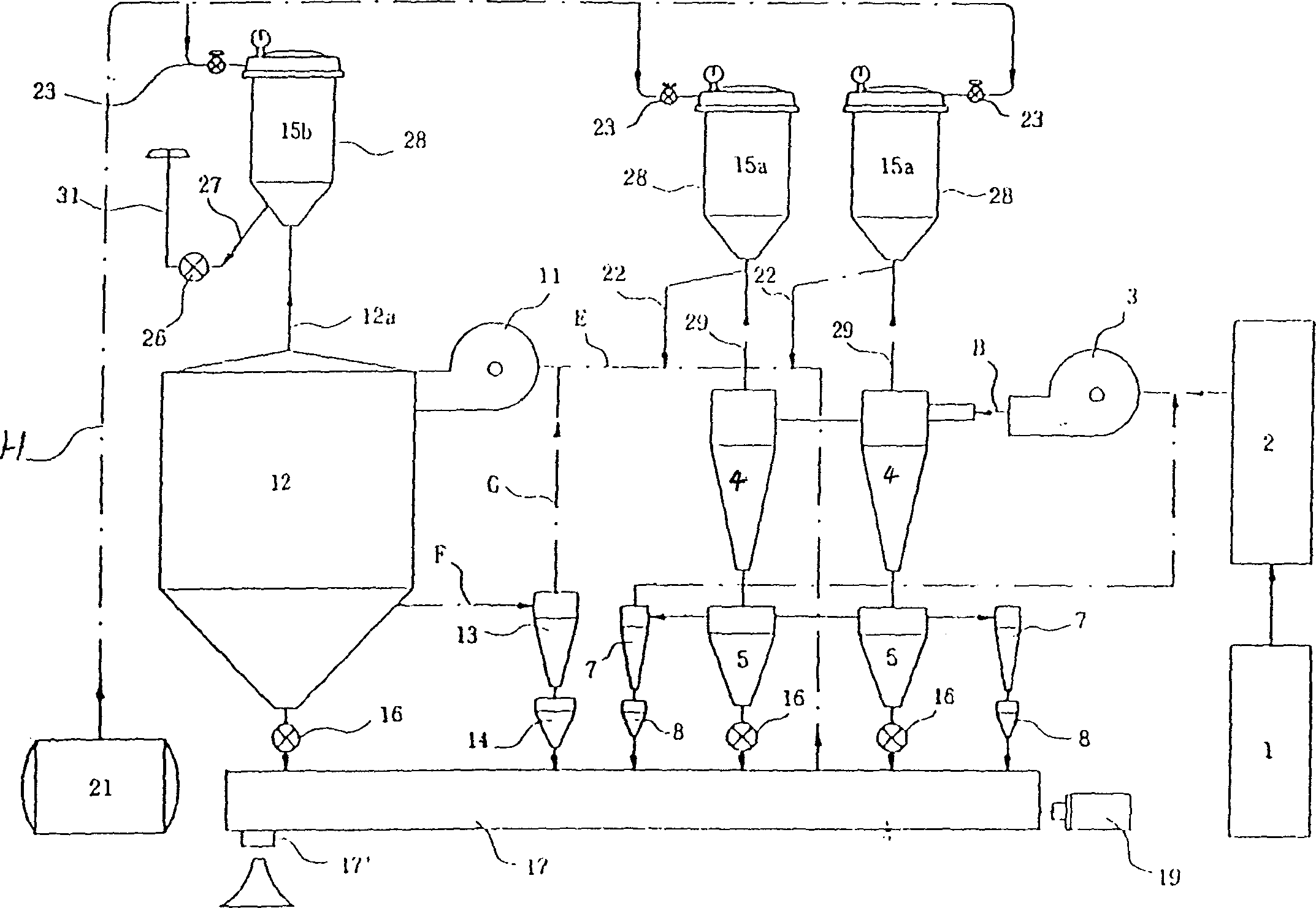

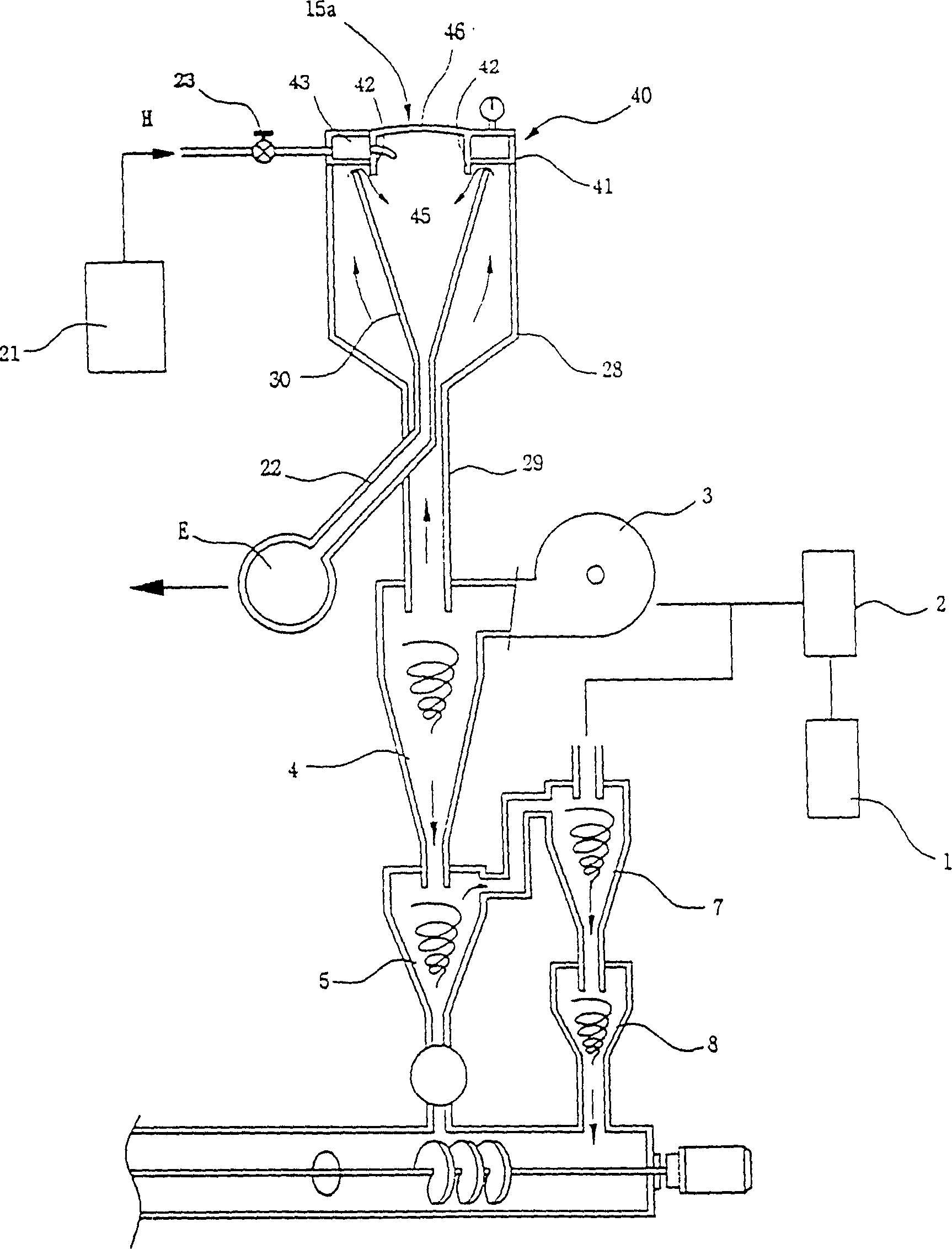

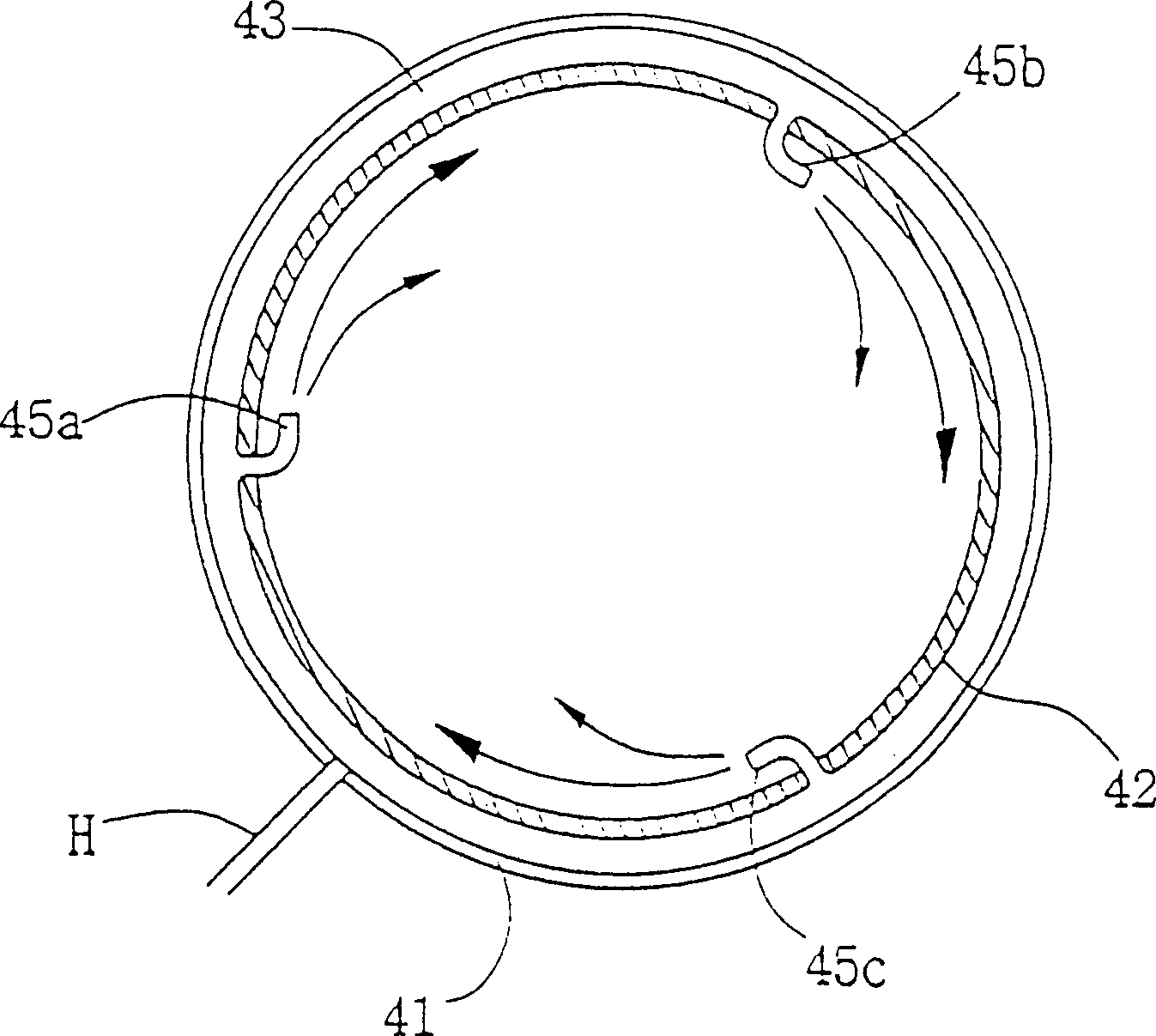

[0020] Such as figure 1 As shown, the exhaust gas treatment system of the present invention is provided with the following components: a cooling machine 2 that is connected to the incinerator 1 and cools the exhaust gas discharged from the incinerator 1; the exhaust gas cooled by the above-mentioned cooling machine 2 is supplied to the main The air blowers 3, 11 of the cyclone 4 and the multi-pipe cyclone 12; the main cyclone 4 (this example is provided with 2 main cyclones 4) that solid particles are removed from the exhaust gas supplied by the above-mentioned air blower 3; The main cyclone 4 on the side does not remove the first auxiliary cyclone 5 (this example is provided with 2 first auxiliary cyclones 5), the second auxiliary cyclone 7 (this example is provided with 2 first auxiliary cyclones) and the fine solid particles that are not removed are removed. 2 auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com