Waste gas treating system

A technology for waste gas treatment and smog, which is used in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, which can solve the problems of incomplete understanding of the composition and properties of tobacco odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

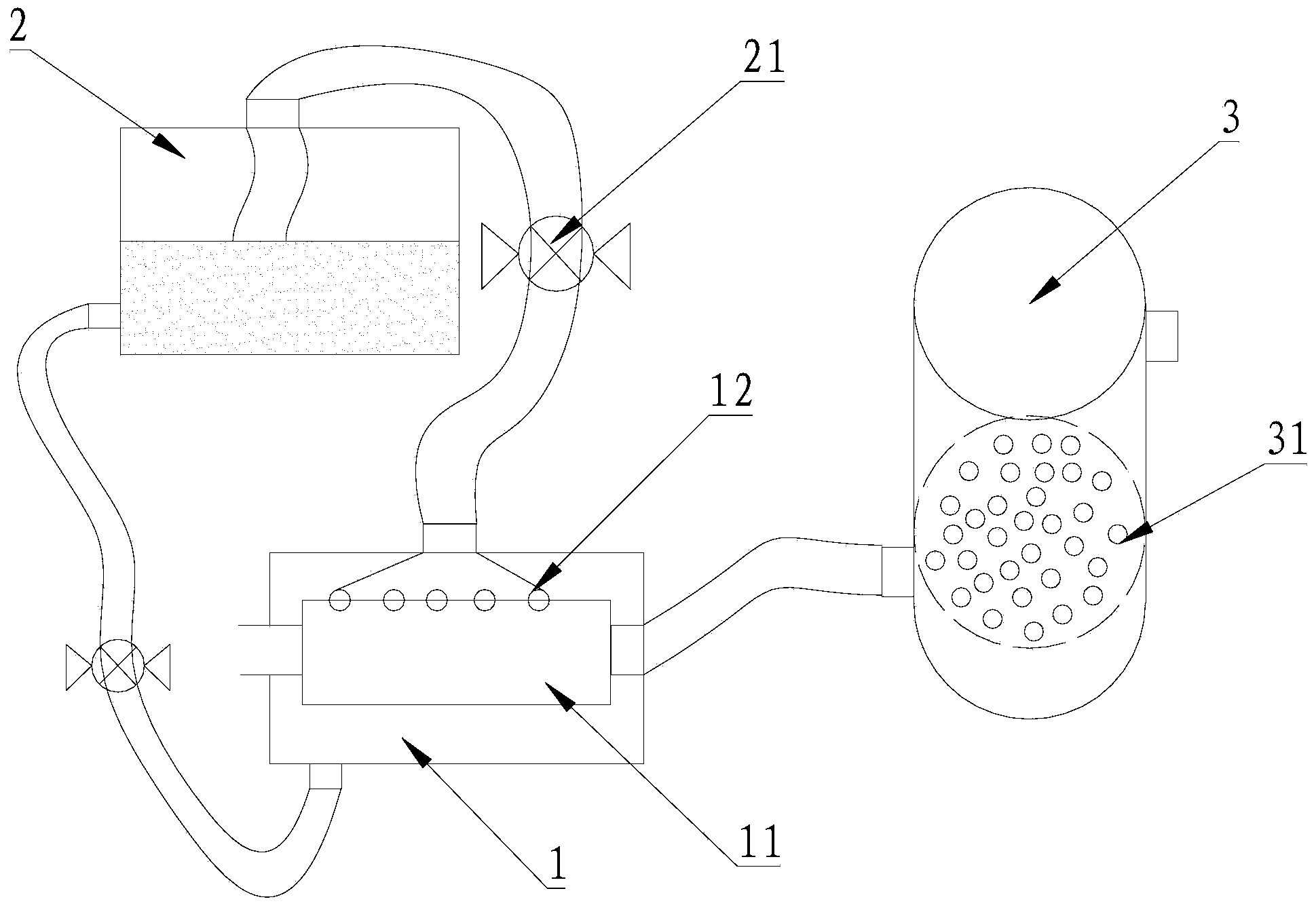

[0020] see figure 1 , as shown in the figure, a waste gas treatment system of the present invention is used for waste gas treatment in the tobacco leaf threshing and redrying process, including a spray room 1, a sedimentation reservoir 2 and a dehydration tower 3; the spray room 1 There is a smoke channel 11 inside, and the front and rear ends of the smoke channel 11 are respectively a smoke inlet and a smoke outlet. Along the smoke channel 11, there are more than one row of nozzles 12, and the bottom of the smoke channel 11 is provided with a drain. The smoke outlet is connected with the moisture exhaust port of the tobacco sheet redrying machine and the tobacco stem redrying machine through a pipe, and the smoke outlet is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com