Organic waste gas treatment system

A treatment system and organic waste gas technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large consumption of activated carbon filter layer, incomplete waste gas treatment, negative pressure instability, etc. , to achieve the effects of small consumption, thorough exhaust gas treatment, uniform ventilation volume and wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

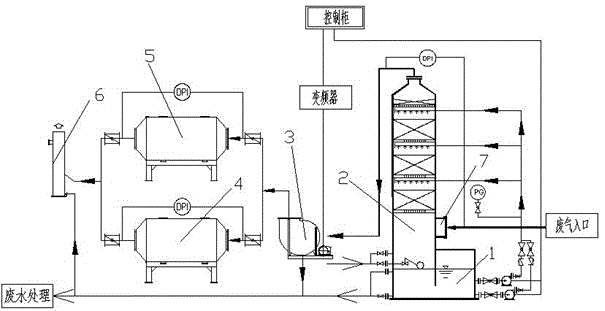

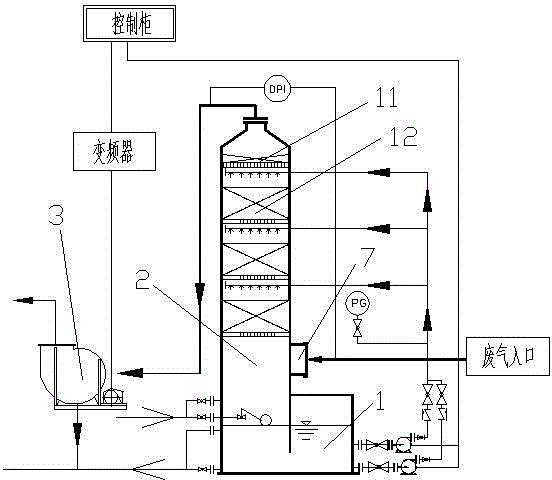

[0017] The present invention is described below in conjunction with accompanying drawing:

[0018] An organic waste gas treatment system, including a suction hood 7, an exhaust pipe system, an electric control system 1 and a waste gas treatment system, characterized in that: the waste gas treatment system includes a wet scrubber 2, an exhaust fan 3 and a dry activated carbon adsorption Tower, dry activated carbon adsorption tower includes dry activated carbon adsorption tower A4 and dry activated carbon adsorption tower B5, dry activated carbon adsorption tower A4 and dry activated carbon adsorption tower B5 are connected in parallel, dry activated carbon adsorption tower A4 is connected in parallel with differential pressure transmission There are butterfly valves for flow control before and after the dry activated carbon adsorption tower A4, and a pressure difference transmitter is connected in parallel with the dry activated carbon adsorption tower B5, and there are butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com