Paint refused-gas treating system and treatment for paint house

A technology for waste gas treatment and paint room, which is applied to coatings, devices for coating liquids on surfaces, etc. It can solve the problems of equipment processing capacity and investment waste, low work reliability, waste of system energy consumption, etc., so as to improve the utilization rate. , The effect of high working reliability and reducing the space occupied by the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

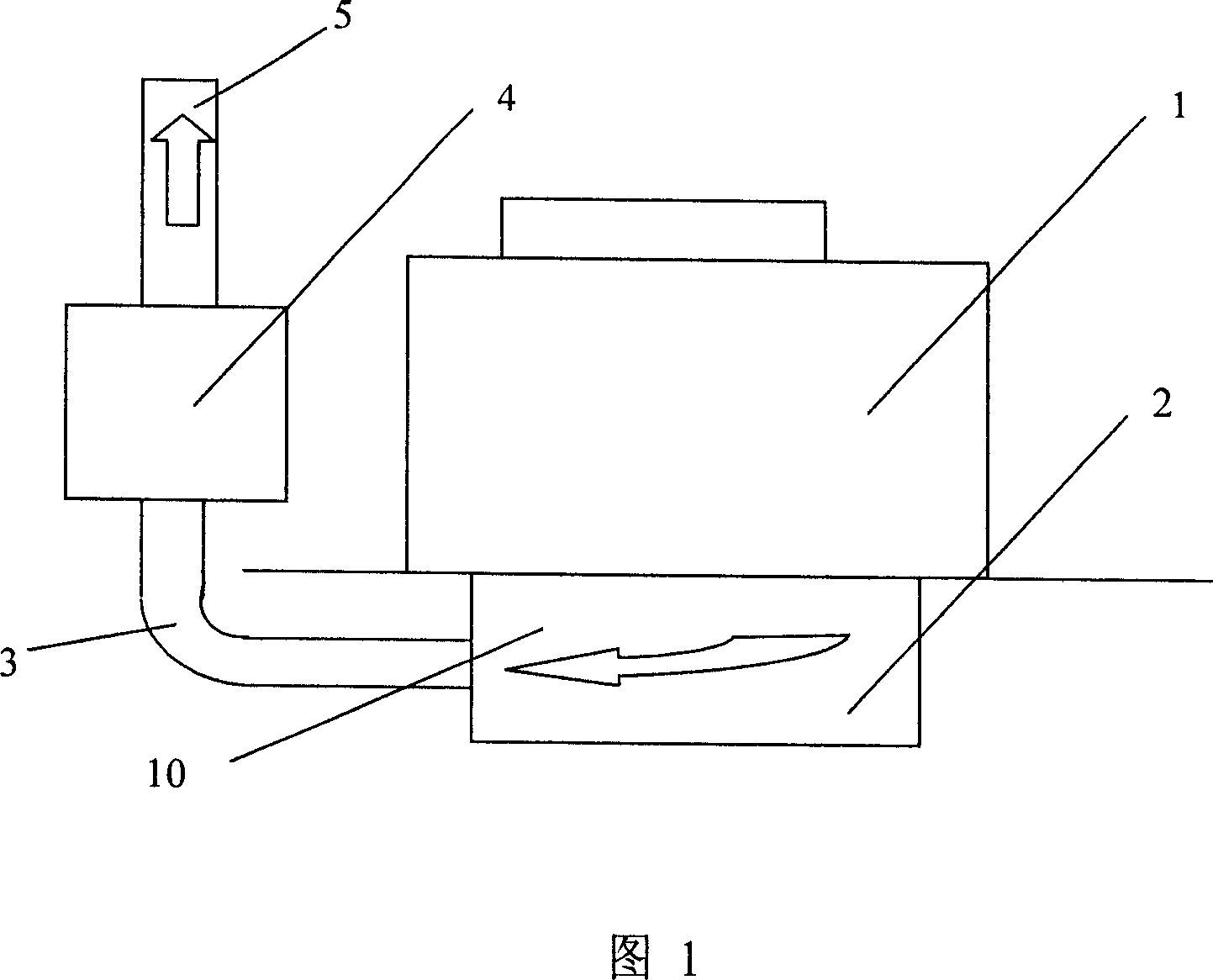

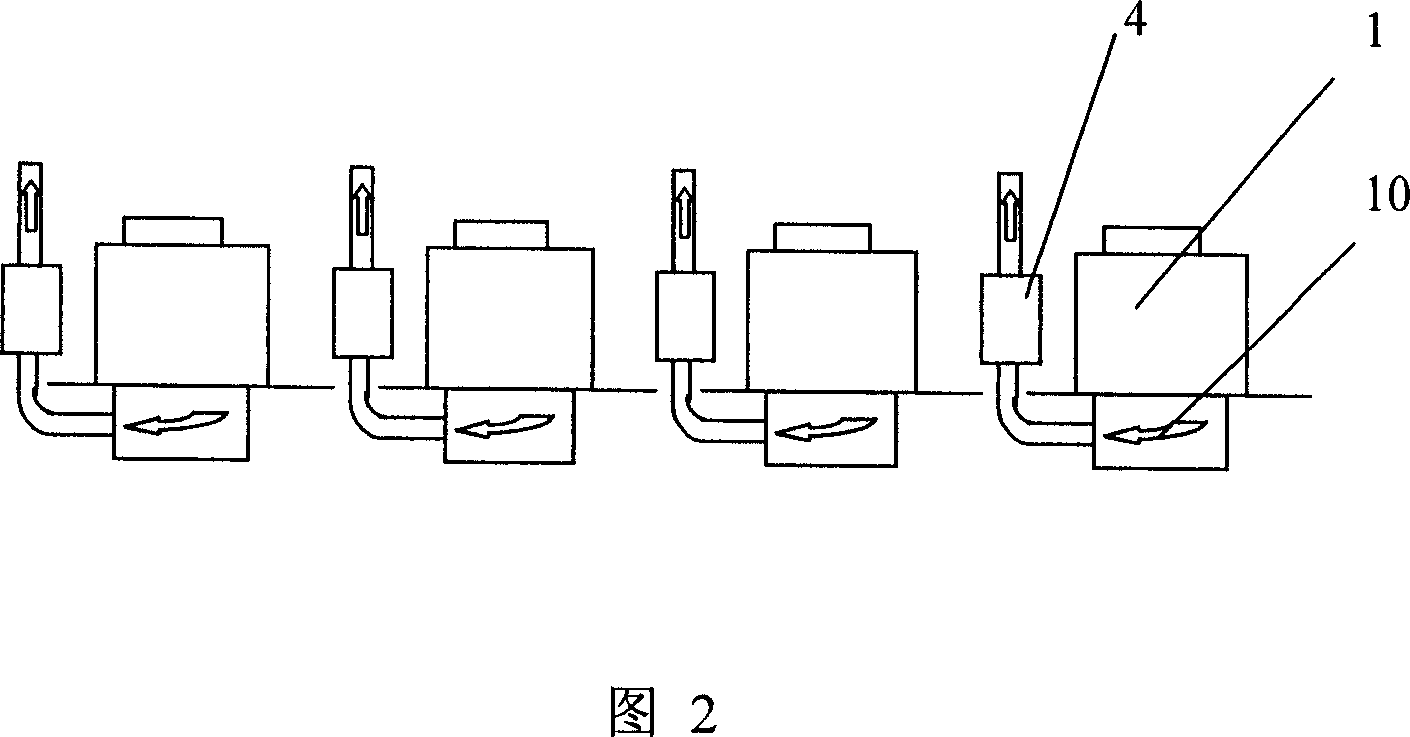

Embodiment approach 1

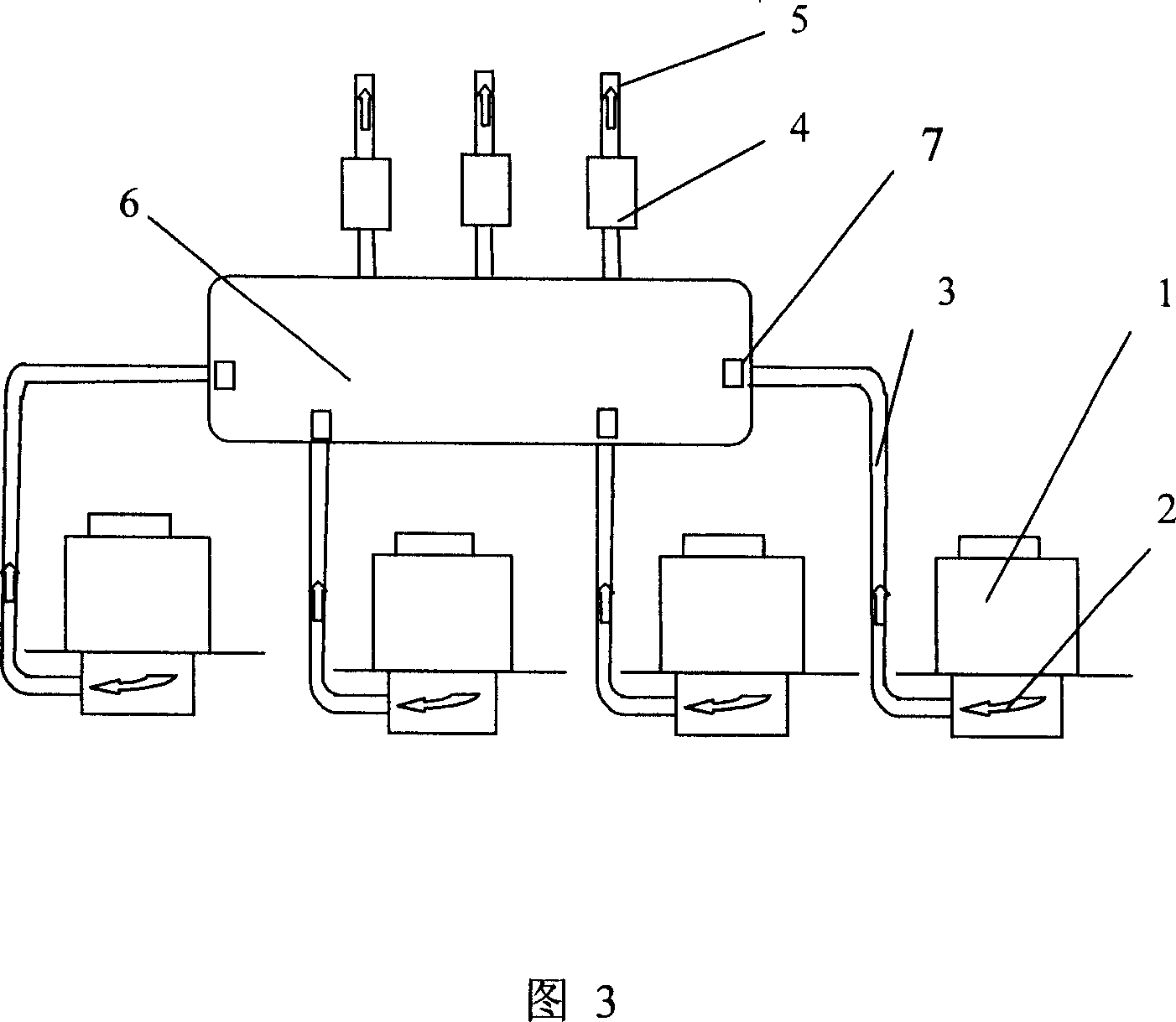

[0037] According to the exhaust gas discharge of the buffer container 6, the number of openings of the secondary purification treatment device 4 is manually controlled, so that the total working exhaust volume of the secondary purification treatment device 4 matches the exhaust gas discharge of the buffer container 6.

Embodiment approach 2

[0039]In order to measure the waste gas displacement of the buffer container 6, automatically control the opening quantity of the secondary purification treatment device 4, measure each waste gas inlet of the buffer container 6 (also can be at the outlet of each primary treatment facility 2, or each one On the outlet of the primary treatment facility 2 and the connection pipeline 3 of the buffer container 6) flow sensors 7 are set, and each flow sensor 7 is connected with a system controller (not shown) signal, and the system controller controls the secondary purification treatment device 4 start and stop.

[0040] When the system controller detects that the total flow of exhaust gas flowing into the buffer container 6 does not match the total working exhaust volume of the working secondary purification treatment device 4 through the flow sensor 7, the working exhaust of the working secondary purification treatment device 4 is adjusted. Gas volume or the quantity of secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com