Waste gas central treating system

A centralized treatment and exhaust gas technology, applied in the direction of cells, electrolytic processes, electrolytic components, etc., can solve problems such as difficult to adjust air volume, unfavorable energy saving, over-design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

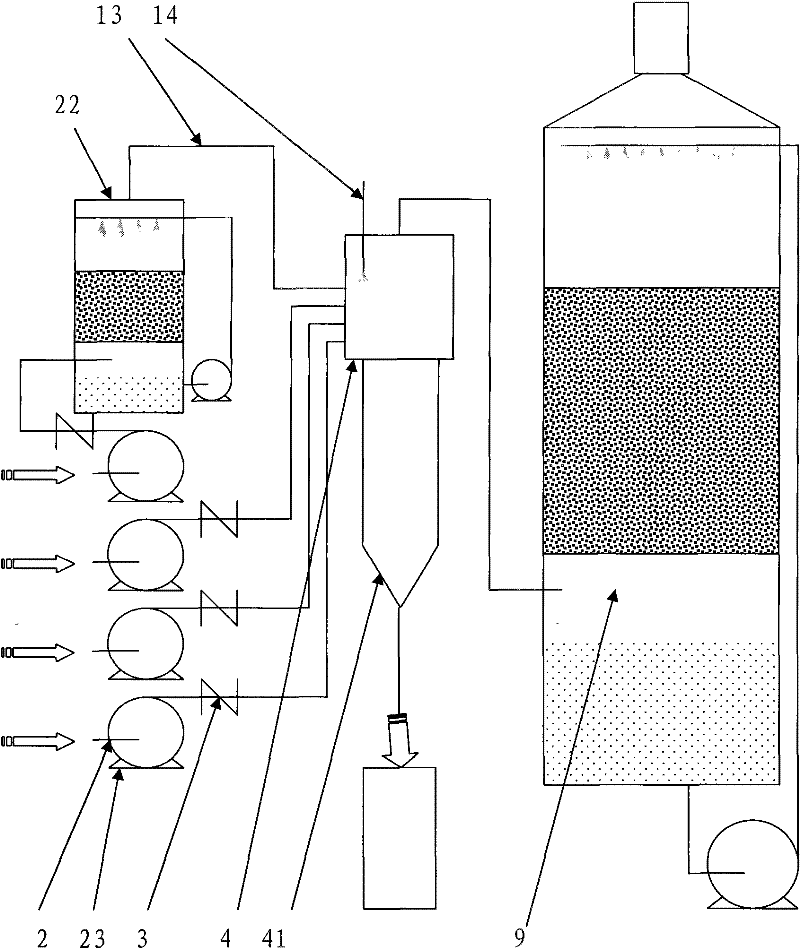

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

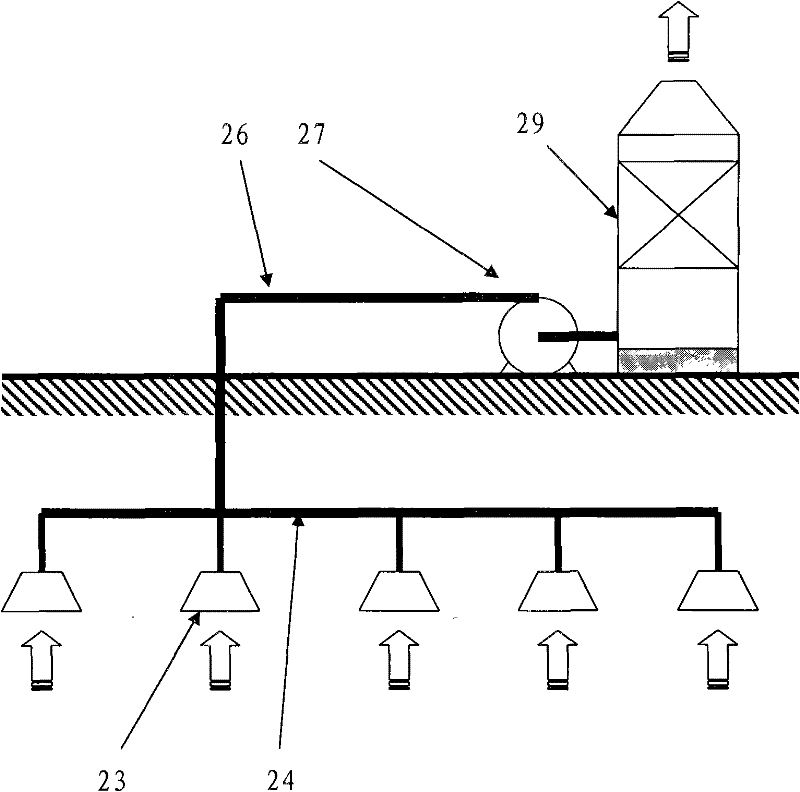

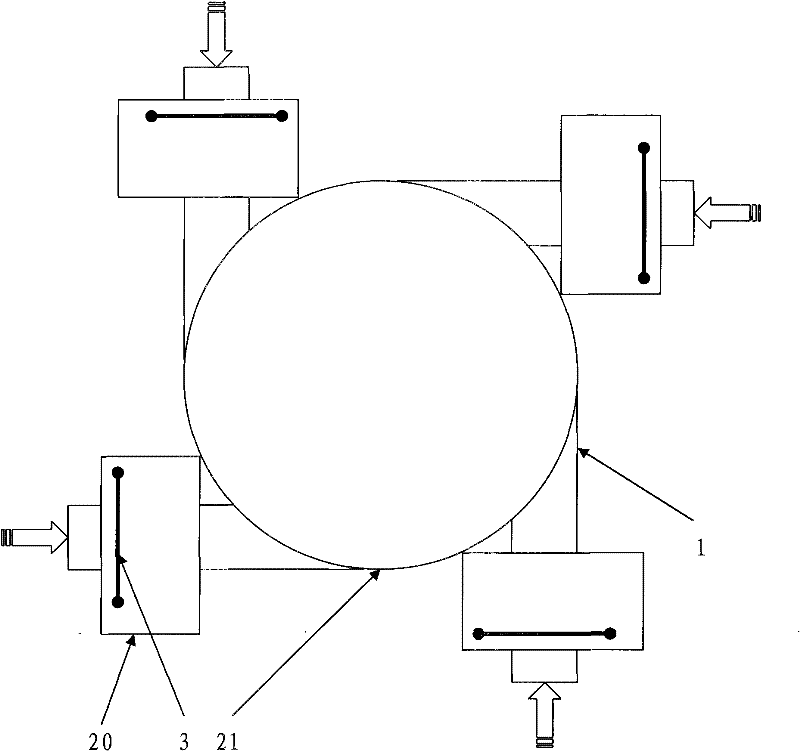

[0014] Such as figure 2 As shown, the system of the present invention is provided with a plurality of air intake branches, as shown in the figure 13, each air intake branch air inlet is equipped with a suction fan, such as label 2, to correspond to different sources of different properties The gas is extracted separately, and each induced draft fan 2 is equipped with an exhaust hood 23 . In addition, a pretreatment device 22 is provided in the air intake branch at the rear end of individual induced draft fans to pre-treat special exhaust gas, thereby improving the final exhaust gas treatment effect. E.g figure 2 In the shown embodiment, for nitric acid waste gas, a urea spray scrubber is added at the rear end of the corresponding induced draft fan to pretreat it.

[0015] The waste gas of each branch needs to be assembled and sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com