A method of removing polymer from and acid gas treating system

An acid gas and polymer technology, applied in the processing of gas mixtures, separation methods, treatment of hydrocarbon oils, etc., can solve problems such as ineffective reduction of regenerator and heat exchanger fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

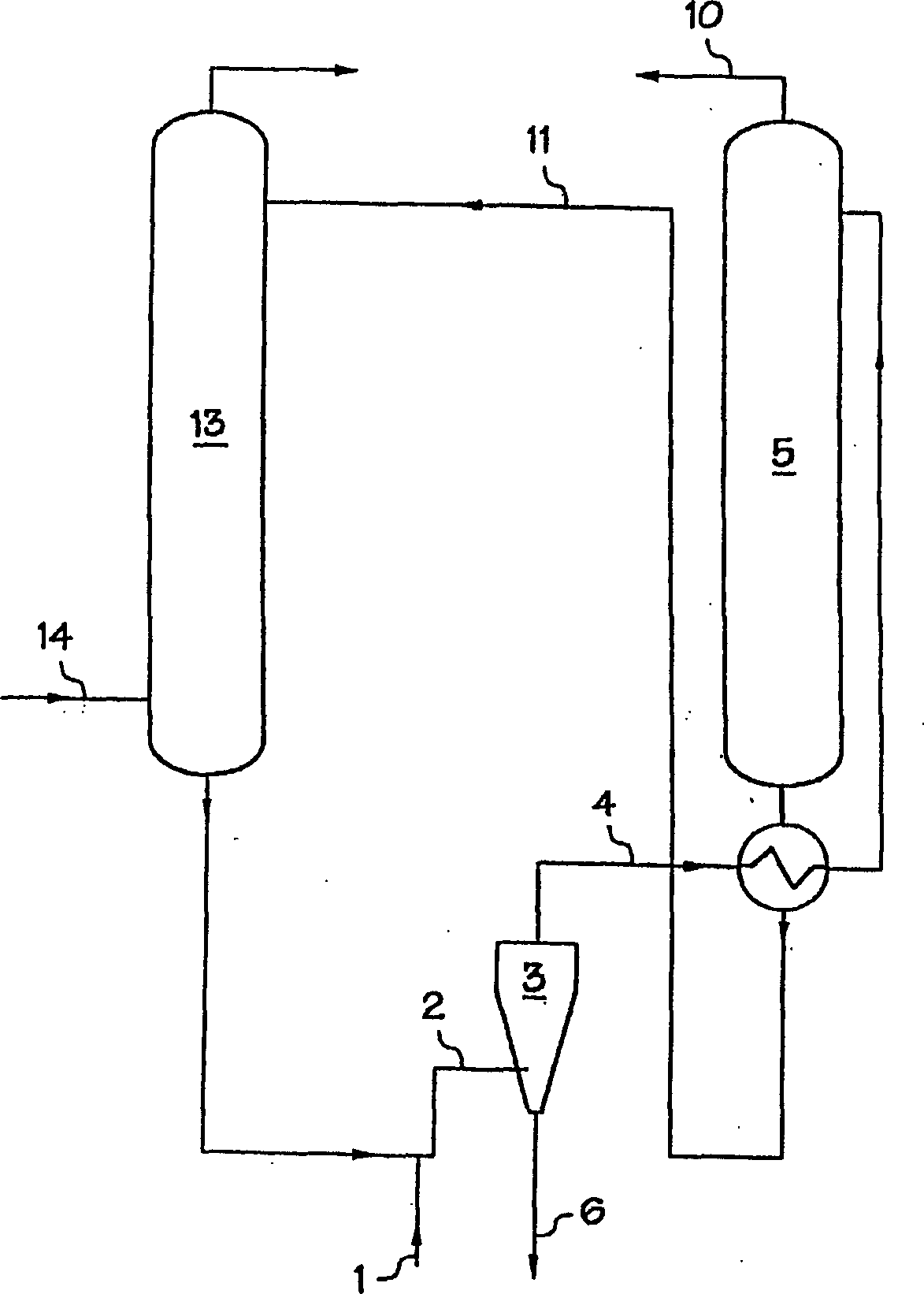

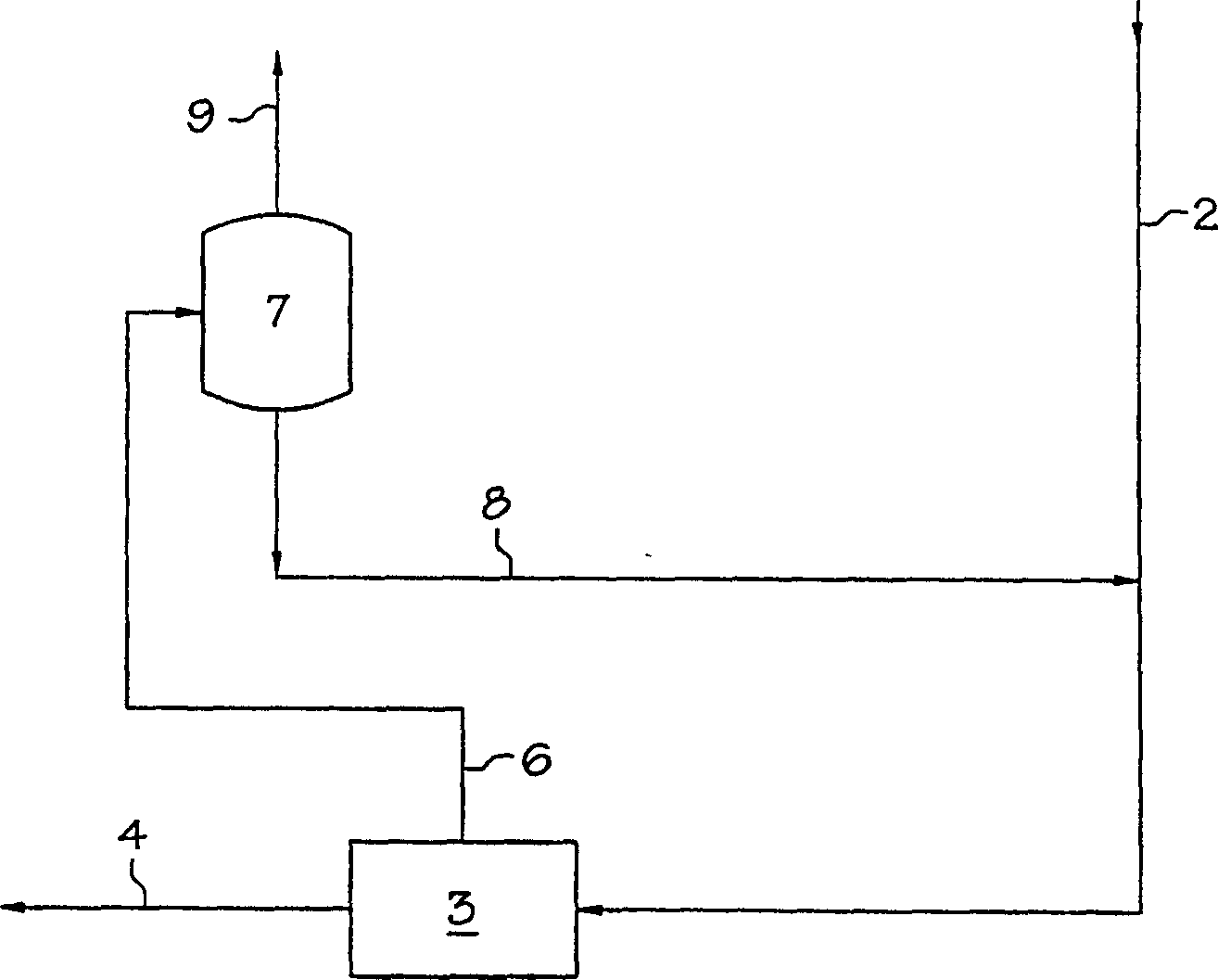

[0036] a. Laboratory tests have shown that a light aromatic solvent (eg, toluene) dissolves the polymer very effectively, but due to its high volatility, losses in the regenerator overhead can be high. b. 1500 liters of Solvesso 200 (a heavy aromatic solvent having at least 99.8 vol % aromatics content, 80 vol % bicyclic aromatics content, a specific gravity of 1.0 and a boiling point range of 232-277° C.) was added to 20% monoethanolamine in the aqueous solution system. The regenerator was operated at 110°C. Spent solvent is recovered by gravimetric separation.

[0037] The fouling tendency of several heat exchangers was monitored during operation and the results showed an improvement in reducing the fouling tendency of the system. In addition, the aforementioned aromatic solvents have sufficiently high boiling points so as not to contaminate the regenerator overhead. However, due to the small difference in specific gravity between the used solvent and the aqueous alkanola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com