Waste gas treatment system and treatment method for waste disposal

A technology for waste gas treatment and garbage treatment equipment, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of secondary air pollution and insufficient stable and effective treatment effects, and achieve stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

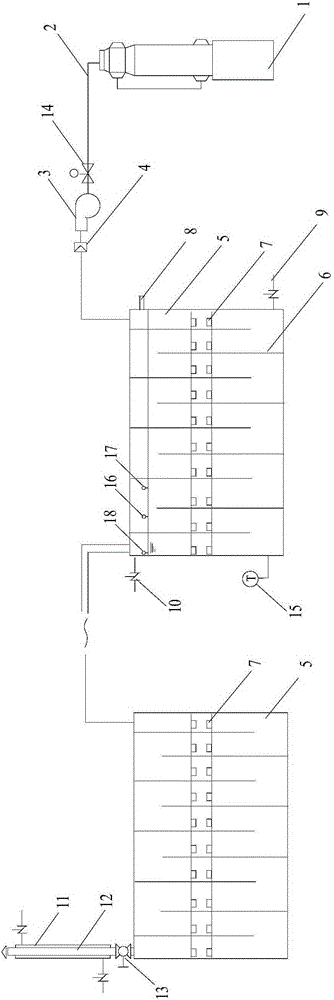

[0034] See figure 1 . Set the salt concentration to 3% PH to 3-4 voltage to 24V and current density to 1000A / m 2 The exhaust gas treatment system produced by various garbage treatment processes, the exhaust gas treatment system includes 20 pressure-bearing electrolytic brine tanks 5 ( figure 1 Only the first and the last one are shown in ), the pressure-bearing electrolytic brine tank 5 is a rectangular container, and N partitions are vertically placed in the pressure-bearing electrolytic brine tank 5, N=81 partitions ( figure 1 are omitted in ), divide the inside of the pressurized electrolytic brine tank into N-1 cavities of equal volume; N is an odd number of partitions that are connected to the top of the pressurized electrolytic brine tank and do not touch the bottom of the pressurized electrolytic brine tank, and N is The even-numbered partitions are connected to the bottom of the pressure-bearing electrolytic brine tank and do not touch the top of the pressure-bearing...

Embodiment 2

[0039] Adopt the waste gas treatment system with the same structure as in Example 1, place pure water with a concentration of 0wt% in the pressurized electrolytic brine tank, the positive and negative plates are evenly distributed in each tank, and the total electrode area of each tank is 88m 2 . The distance between the positive plate and the negative plate is 0.2cm, and the current density is 2200A / m 2 current, voltage 24V. In this embodiment, the garbage disposal device is an incinerator. The 800°C waste gas produced by waste incineration is passed into the waste gas treatment system under the pressure of 4 Pa (ie, the pressure of the induced draft fan), and electrolysis occurs in the non-salt water tank. After continuous electrolysis reaction through 22 water tanks, the waste gas is discharged.

[0040] The pH value of the saline is adjusted to 8.6-9.5 with sodium hydroxide.

[0041] Every 5-24 hours of operation, change the polarity of the positive and negative pla...

Embodiment 3

[0044] Using the exhaust gas treatment system of Example 1, place brine with a concentration of 6wt% in the pressurized electrolytic brine tank, the distance between the positive plate and the negative plate is 1 cm, and the current density is 1400A / m 2 current, the positive and negative plates are evenly distributed in each slot, and the total electrode area of each slot is 10m 2 . Positive and negative plate voltage 12V. In this embodiment, the garbage disposal device is a biochemical garbage disposal device. The exhaust gas produced by biochemical treatment is passed into the exhaust gas treatment system under the pressure of 2 Pa (ie, the pressure of the induced draft fan), electrolyzed in salt water, and then discharged.

[0045] The pH value of the saline is adjusted to 8.6-9.5 with sodium hydroxide.

[0046] Every 24 hours of operation, change the polarity of the positive and negative plates by changing the direction of the positive and negative power supply. Circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com