Waste-gas treating system

A waste gas treatment and pretreatment technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of short service life, poor treatment effect, waste of water source, etc., achieve uniform mixing, better treatment effect, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

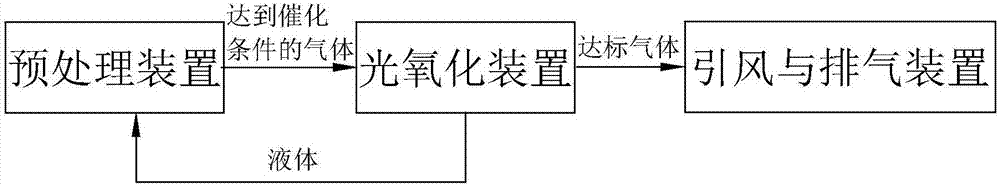

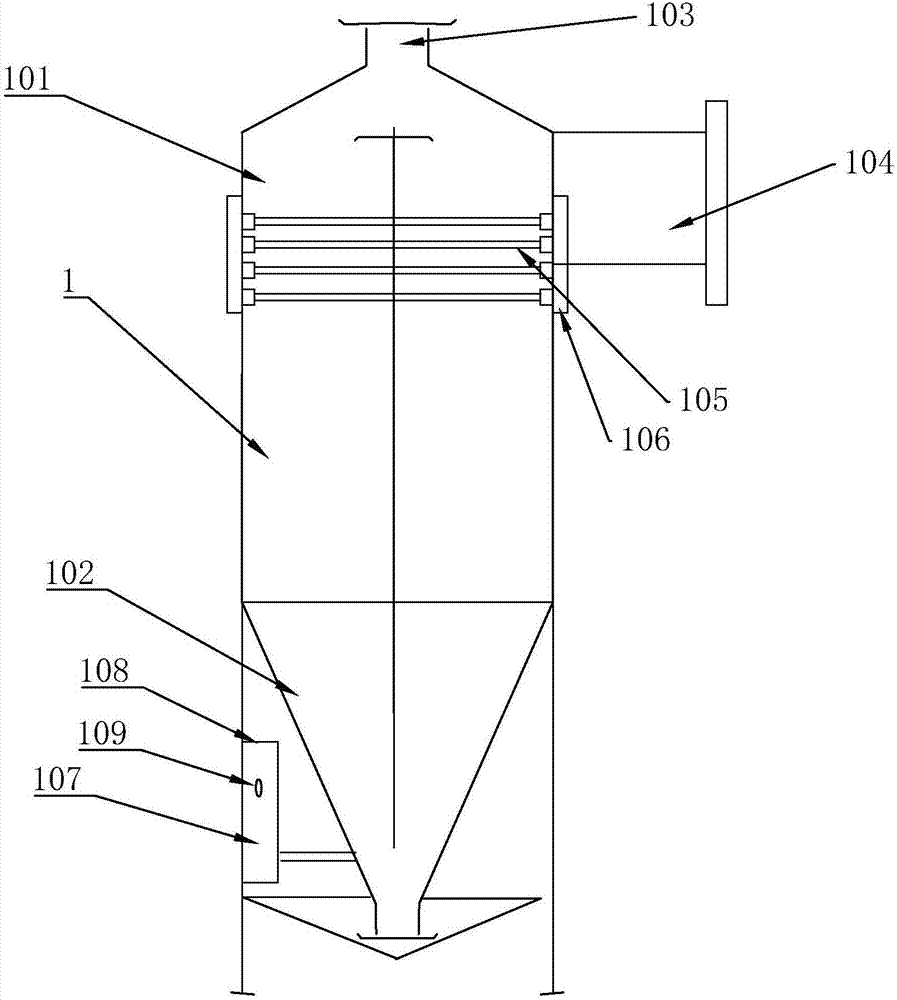

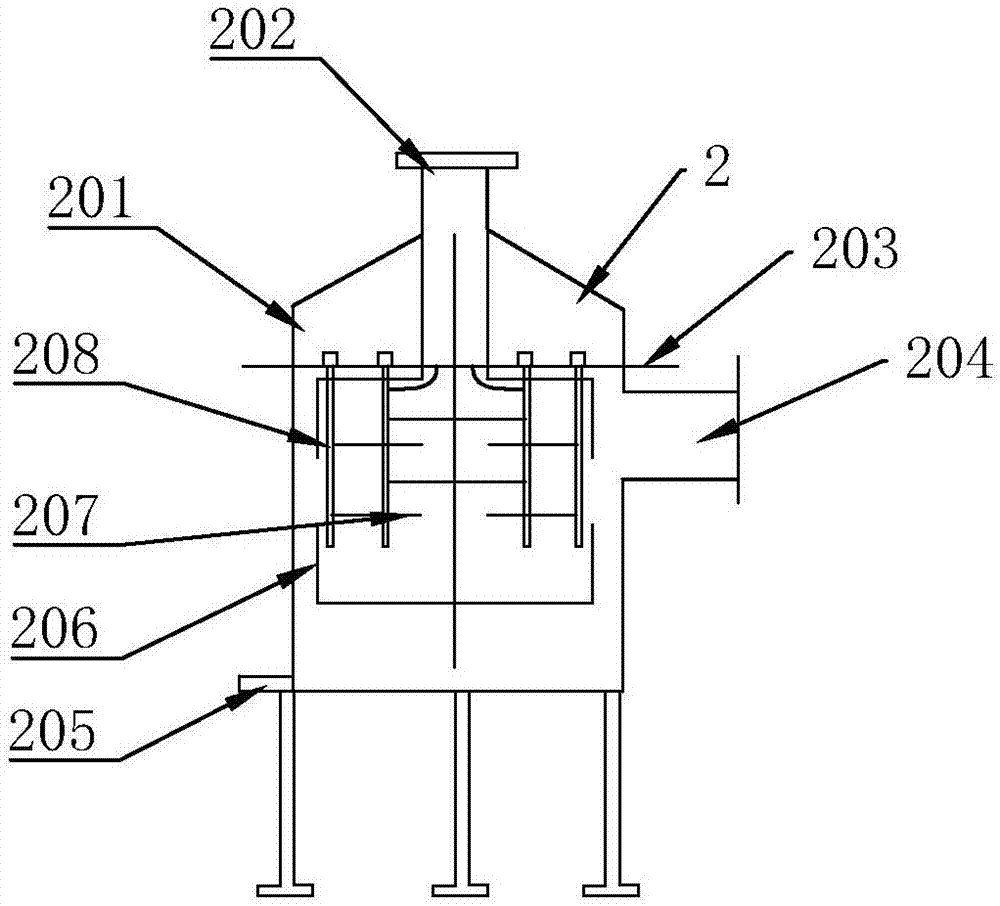

[0032] Such as figure 1 As shown, an exhaust gas treatment system of the present invention includes a pretreatment device 1 , a photooxidation device 2 and an air induction and discharge device 3 connected in sequence.

[0033] The air induction and discharge device 3 extracts air from the pretreatment device 1 and the photooxidation device 2, so that the inside of the pretreatment device 1 and the photooxidation device 2 are always in a negative pressure state, and the pretreatment device 1 is under negative pressure conditions to treat the exhaust gas Carry out catalysis, so that the exhaust gas reaches the catalytic condition and enters the photooxidation device 2. The photooxidation device 2 further processes the exhaust gas that meets the catalytic condition, decomposes and destroys the harmful substances in the exhaust gas, until the discharge condition is met, and finally, through the induced wind The exhaust device 3 discharges the gas that meets the emission standards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com