Combustion chamber structure of waste gas treating system

A technology of waste gas treatment and combustion chamber, which is applied in the direction of combustion chamber, combustion method, combustion type, etc., can solve the problems of corrosion and fracture of heating rod, corrosion of combustion chamber, corrosion and peeling of the surface layer of combustion chamber, etc., and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

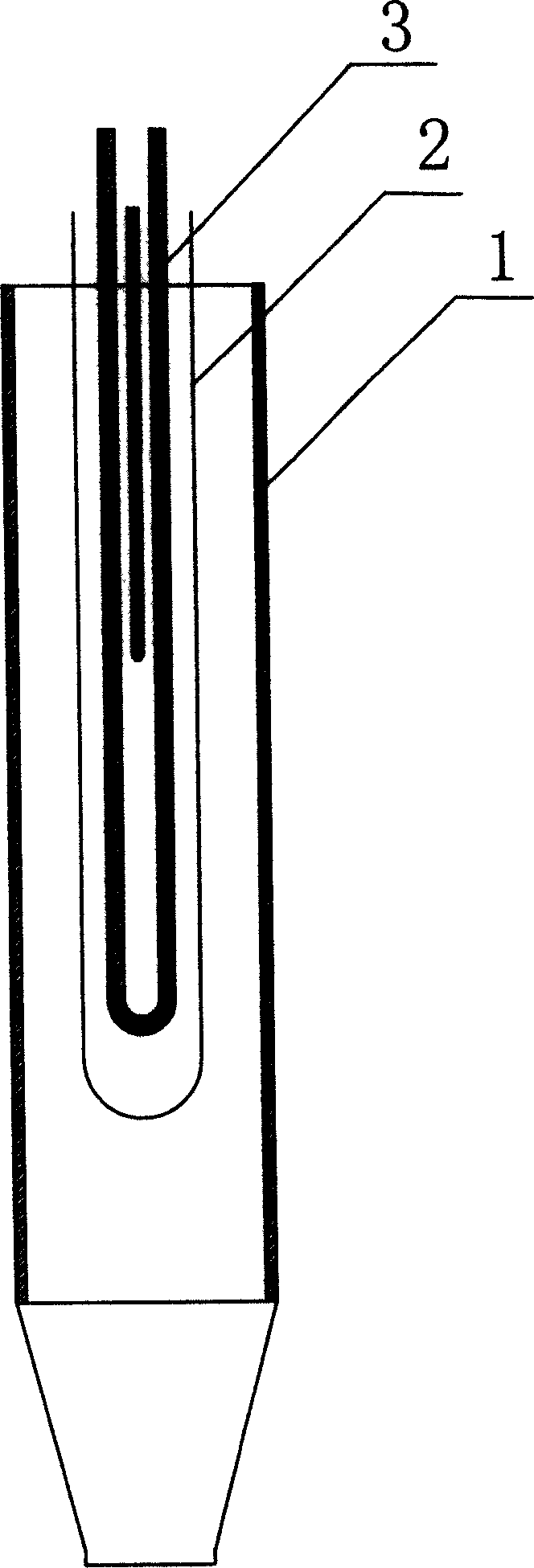

Image

Examples

Embodiment 1

[0018] A zirconia composite coating is added to the inner wall of the combustion chamber. The coating has strong corrosion resistance, high temperature resistance and erosion resistance.

[0019] kind

[0020] Zirconium silicate and zircon powder composite coating is used on the inner wall of the combustion chamber. This composite coating has a high melting point, high temperature resistance, and strong corrosion resistance. Some exhaust gases and harmful gases enter the combustion chamber. It can resist corrosion at the same time , to effectively treat these gases so that the discharged gases meet environmental protection standards.

Embodiment 2

[0022] Aluminum oxide or aluminum oxide composite coating 1 is added to the inner wall of the combustion chamber. The coating has strong corrosion resistance, high temperature resistance, stable high temperature chemical properties, wear resistance and erosion resistance.

[0023] chemical composition(%)

[0024] A composite coating of alumina and zirconia is used on the inner wall of the combustion chamber. Both alumina and zirconia are ceramics. Alumina has high temperature resistance, high strength, wear resistance, and corrosion resistance. Zirconia has high density and relatively high hardness. High, flexural strength and fracture toughness are the highest performance among all kinds of ceramics. The composite coating of the two has high melting point, high temperature resistance and strong corrosion resistance. Some waste gas and harmful gas enter the combustion chamber, it can be in While resisting corrosion, these gases are effectively treated to make the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com