Process flow for separating low-carbon hydrocarbons and separating gas during production of olefins (M-OS/MTO) from methanol

A technology for methanol to olefins and gas separation, which is applied in the direction of absorption purification/separation, distillation purification/separation, ethylene production, etc. It can solve the problems of large towers and other equipment, long circulation routes, and large amount of absorbents, etc., to achieve reduction Investment and energy consumption, avoiding an increase in energy consumption, and enhancing the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

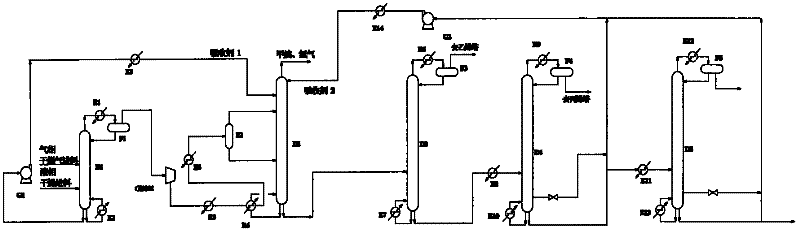

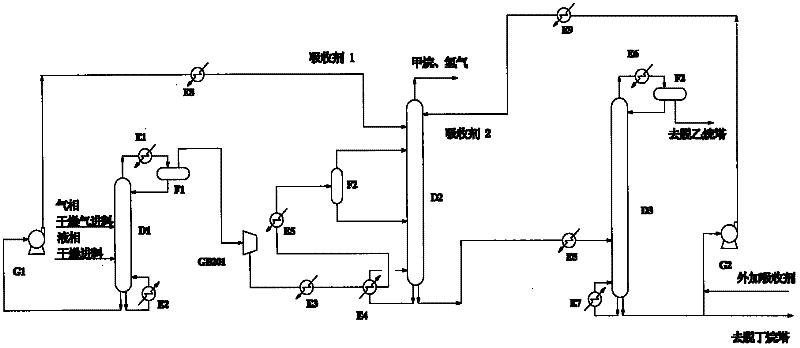

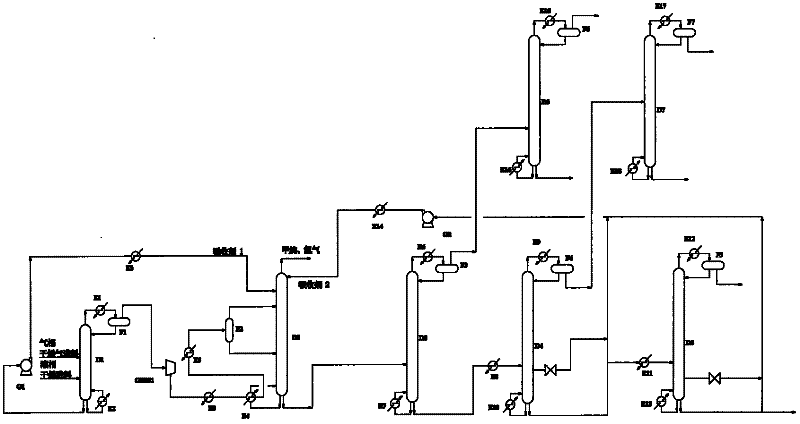

Image

Examples

Embodiment Construction

[0028] The following is an embodiment of the present invention, based on the composition of the methanol-to-olefins reaction gas with an annual output of 600,000 tons of olefins in a plant as the feed, wherein the ratio of ethylene to propylene is about 1:1, and the attached image 3 The process flow is separated. The protection scope of the present invention is not limited to the following specific embodiments.

[0029] In this embodiment, the reaction gas produced by methanol through catalytic reaction is gradually increased to 2.0 MPaG, and after cooling, it is divided into two phases of gas and liquid, which are respectively sent into the drying system for drying. The dried reaction gas enters the absorbent separation tower D1, the top of the absorbent separation tower is mainly methane, hydrogen, carbon two and some carbon three, and the main components of the tower bottom are carbon three, carbon four and the recombination of carbon four or more points, is an unclear pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com