Refinery dry gas separation method and refinery dry gas separation apparatus

A technology of refinery dry gas and separation method, which is applied in the directions of absorption purification/separation, distillation purification/separation, climate sustainability, etc. Ideal effect, lower investment, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

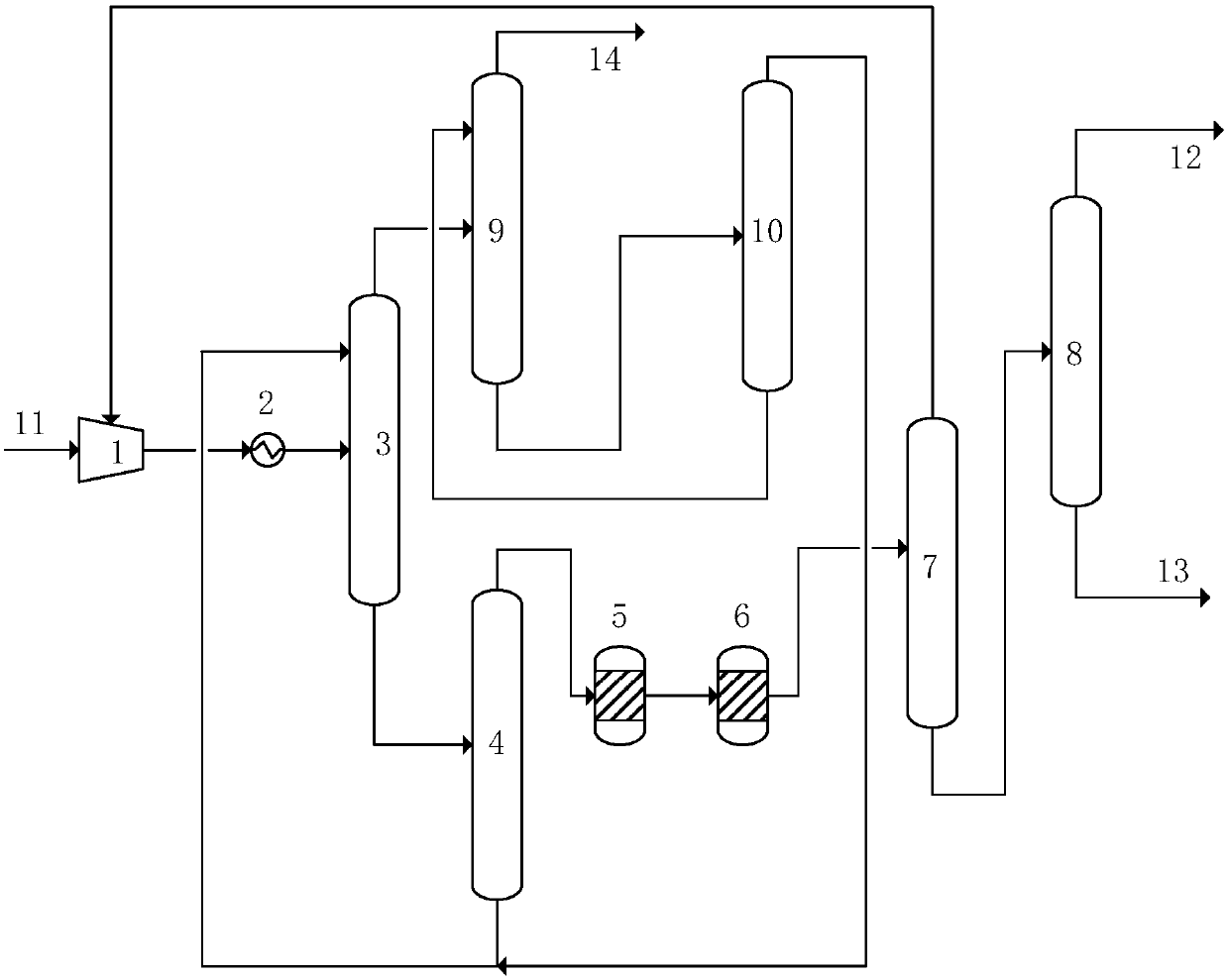

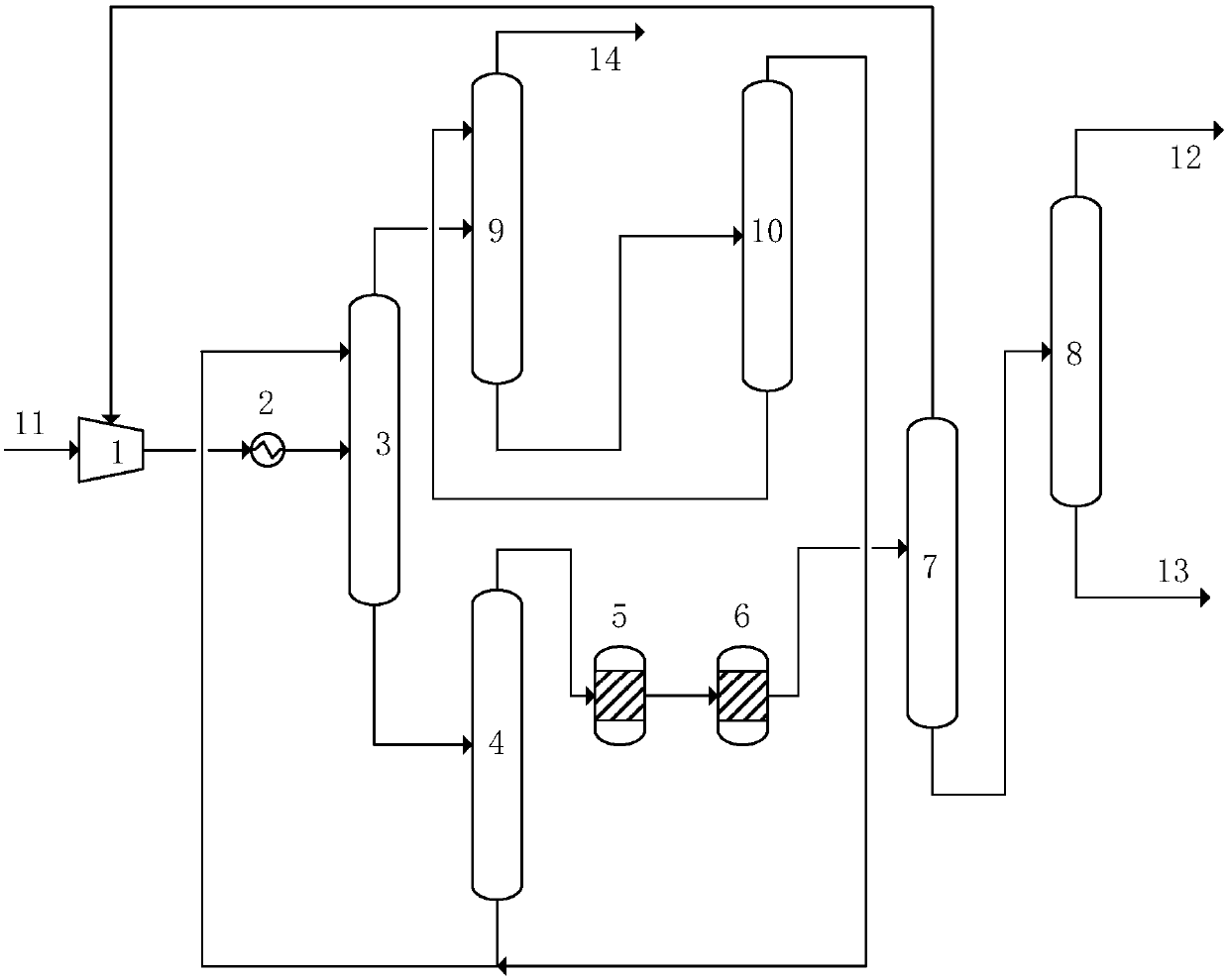

Embodiment 1

[0058] use as figure 1 Refinery dry gas separation unit shown. Including: a compressor 1, a cooler 2, an absorption tower 3, a desorption tower 4, a purification unit 5, a drying unit 6, a demethanizer 7 and an ethylene rectification tower 8; the top of the absorption tower 3 is connected to a reabsorption tower 9 and Gasoline stabilization tower 10, the bottom of the tower is connected to the desorption tower 4; the top of the desorption tower 4 is connected to the purification unit 5 and the drying unit 6 in turn, and then connected to the demethanizer 7; the top of the demethanizer 7 is connected to the first section of the compressor , the bottom of the tower is connected to the ethylene rectification tower 8; the top of the ethylene rectification tower 8 is connected to the production line of the polymer grade ethylene product, and the bottom of the tower is connected to the production line of the rich ethane product; the bottom of the gasoline stabilization tower 10 is c...

Embodiment 2

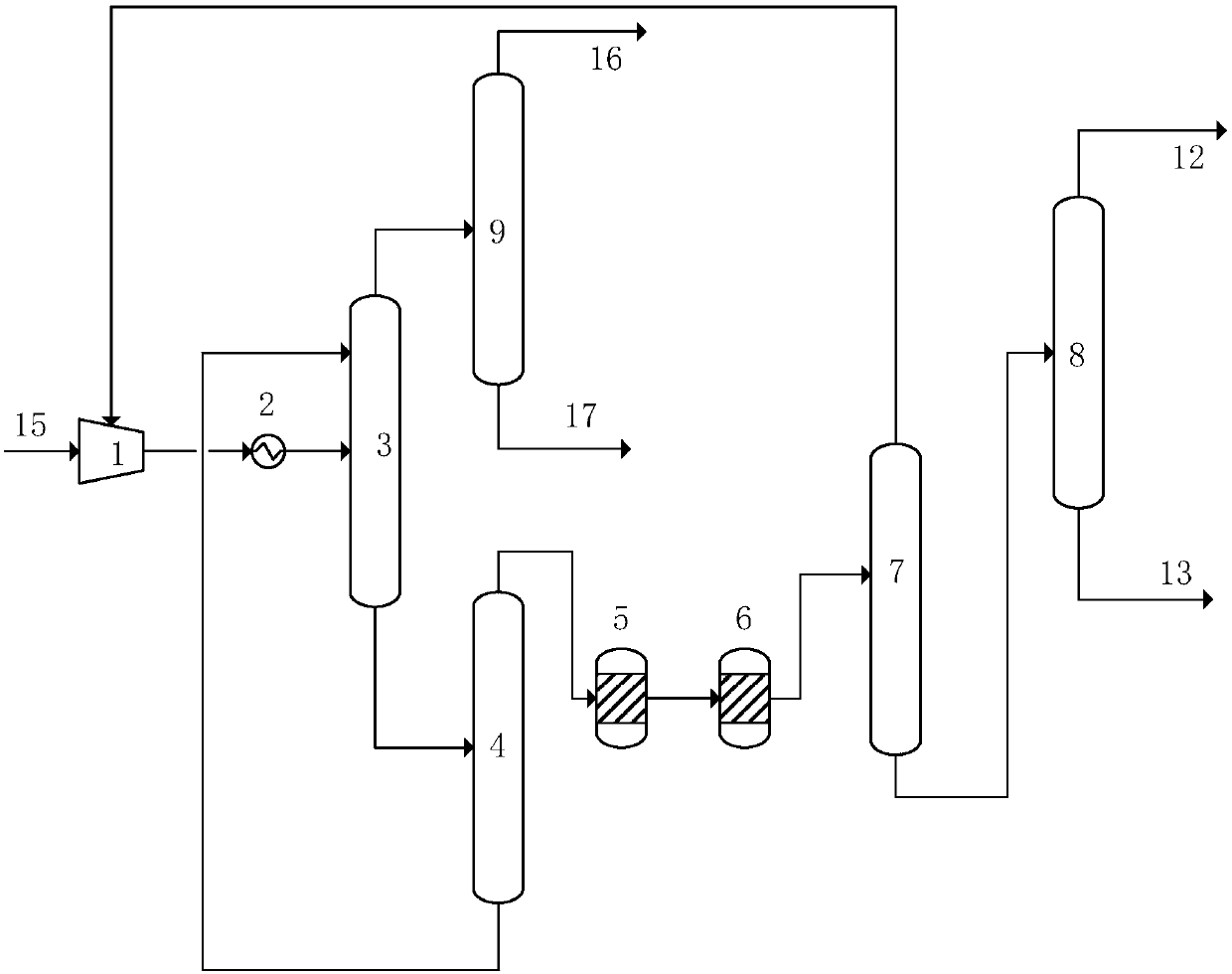

[0078] use as figure 2 In the shown separation device, crude gas 15 (dry gas, see Table 3 for composition) from a factory enters the separation device.

[0079] The separation device comprises: a compressor 1, a cooler 2, an absorption tower 3, a desorption tower 4, a purification unit 5, a drying unit 6, a demethanizer 7 and an ethylene rectification tower 8; Tower 9, the bottom of the tower is connected to the desorption tower 4; the top of the desorption tower 4 is connected to the purification unit 5 and the drying unit 6 in turn, and then connected to the middle part of the demethanizer 7, and the bottom of the tower is connected to the top of the absorption tower 3; the top of the demethanizer 7 The top is connected to the section 1 of the compressor, and the bottom of the tower is connected to the middle part of the ethylene rectification tower 8.

[0080] The separation method includes the following steps:

[0081] (1) Compression: the crude gas 15 from a certain fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com