Method for separating low-carbon olefins

A low-carbon olefin and separation method technology, applied in the purification/separation of hydrocarbons, hydrocarbon production from carbon oxides, absorption purification/separation, etc., can solve inappropriate problems, achieve good applicability, reduce equipment investment and energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

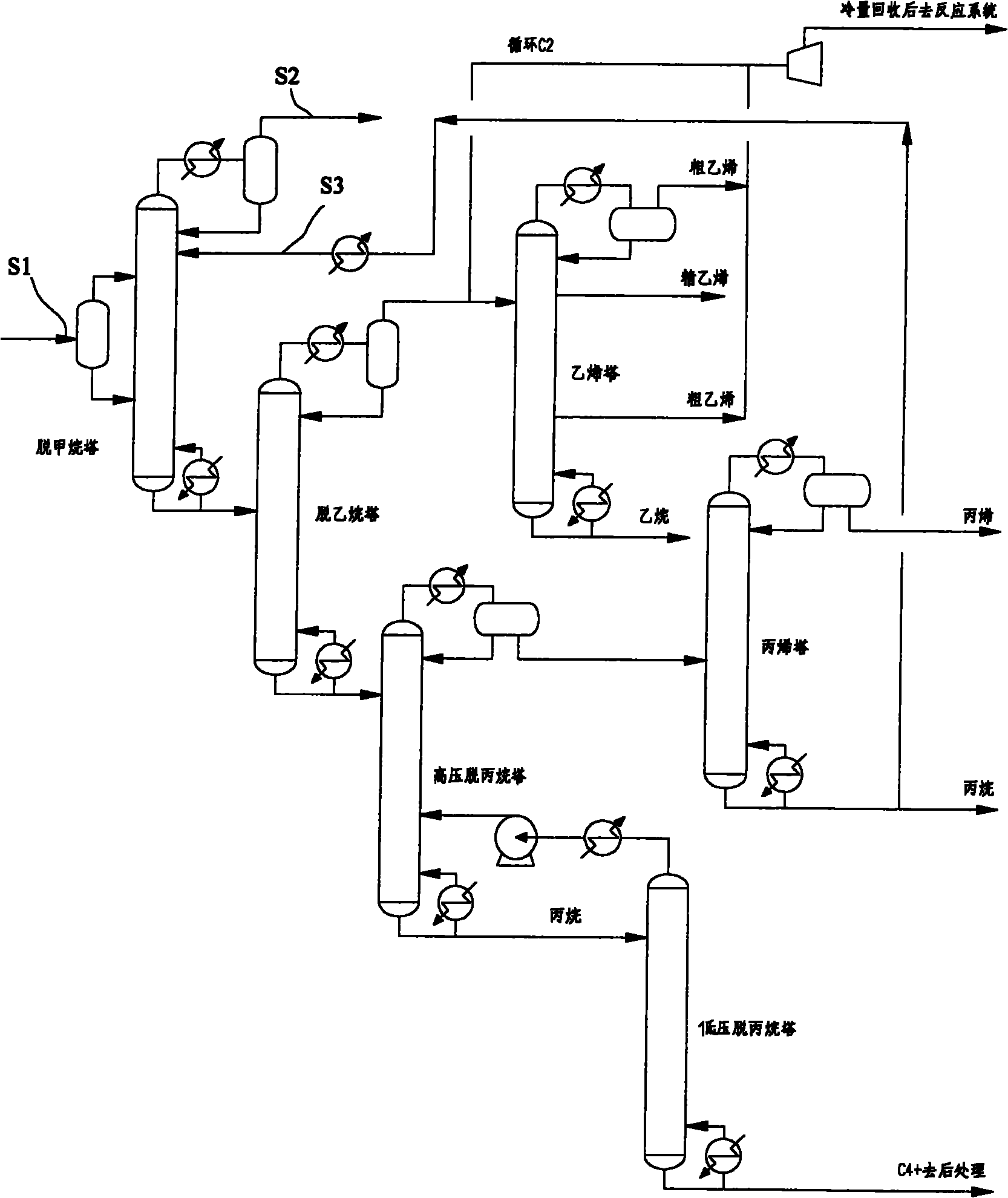

[0032] Such as figure 1 , the low-carbon hydrocarbons from the reaction are cooled after quenching, compression and impurity removal. Under the conditions of 3.2MPa and -30°C, they first enter the feed separation tank of the demethanizer for gas-liquid separation. The demethanizer uses propane as the absorbent , where the temperature of the propane absorbent is -20°C. The top of the demethanizer is CH 4 、H 2 , CO and N 2 Etc. light components and partially lost propane absorbent, the C2+ components at the bottom of the demethanizer, directly enter the deethanizer. All the C2 at the top of the deethanizer goes to the ethylene tower, and does not circulate back to the reaction system, and the C3+ at the bottom of the deethanizer goes into the depropanizer. Refined ethylene is extracted from the side line of the ethylene tower, crude ethylene is removed from the compression system at the top of the tower, crude ethylene is not extracted from the lower side line, and the botto...

Embodiment 2

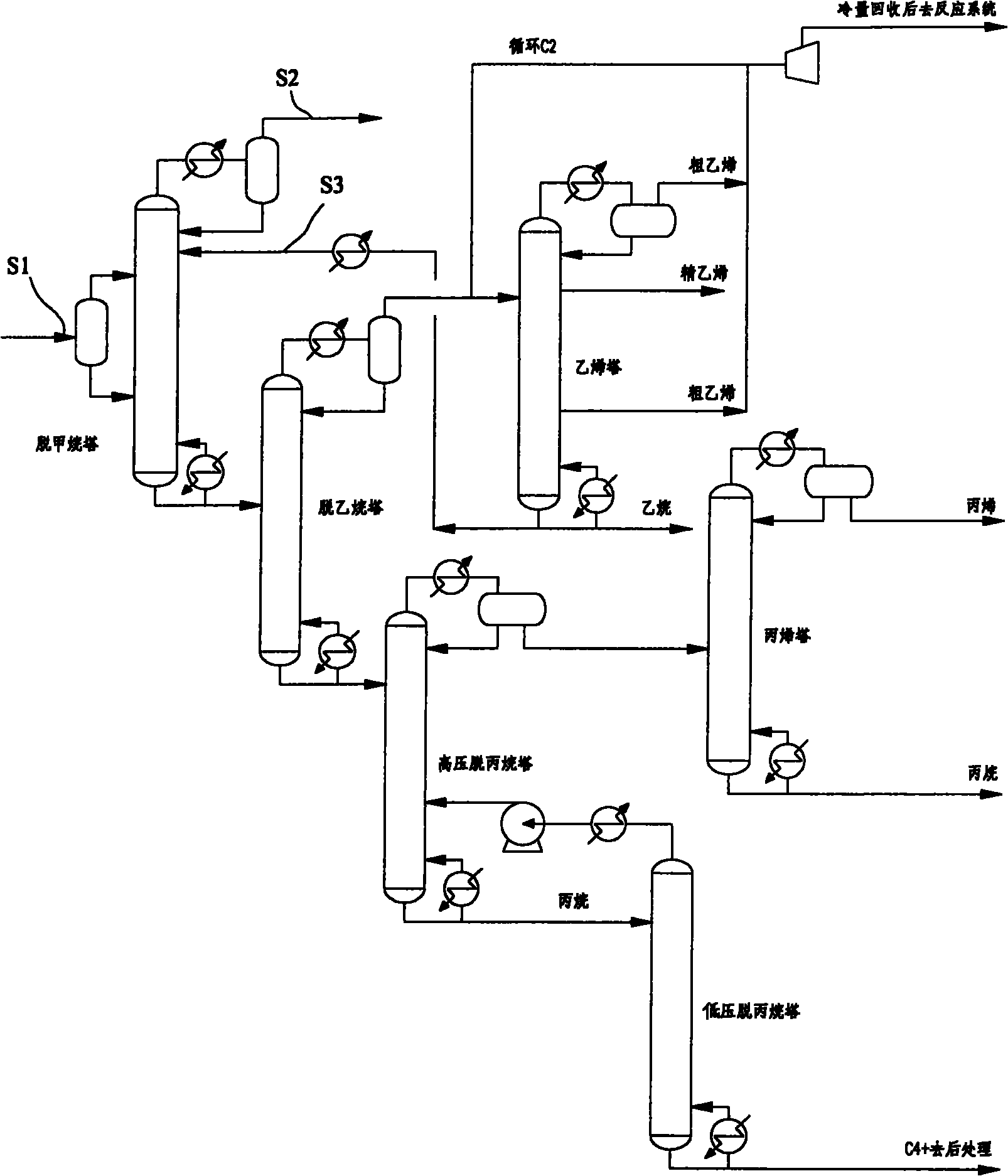

[0038] Such as figure 2 , the low-carbon hydrocarbons from the reaction are cooled after quenching, compression and impurity removal. Under the conditions of 3.2MPa and -30°C, they first enter the demethanizer feed separation tank for gas-liquid separation. The demethanizer uses ethane as absorption agent, where the temperature of the ethane absorbent is -20°C. The top of the demethanizer is CH 4 、H 2 , CO and N 2 Etc. light components and partially lost ethane absorbent, the bottom of the tower is C2+ components, which directly enter the deethanizer. Part of the C2 at the top of the deethanizer goes to the ethylene tower, and part of it is recycled to the reaction system, and the C3+ at the bottom of the deethanizer enters the depropanizer. Refined ethylene is extracted from the side line of the ethylene tower, crude ethylene is extracted from the top and side line of the tower, and part of the C2 extracted from the top of the deethanizer is recovered by the expander and...

Embodiment 3

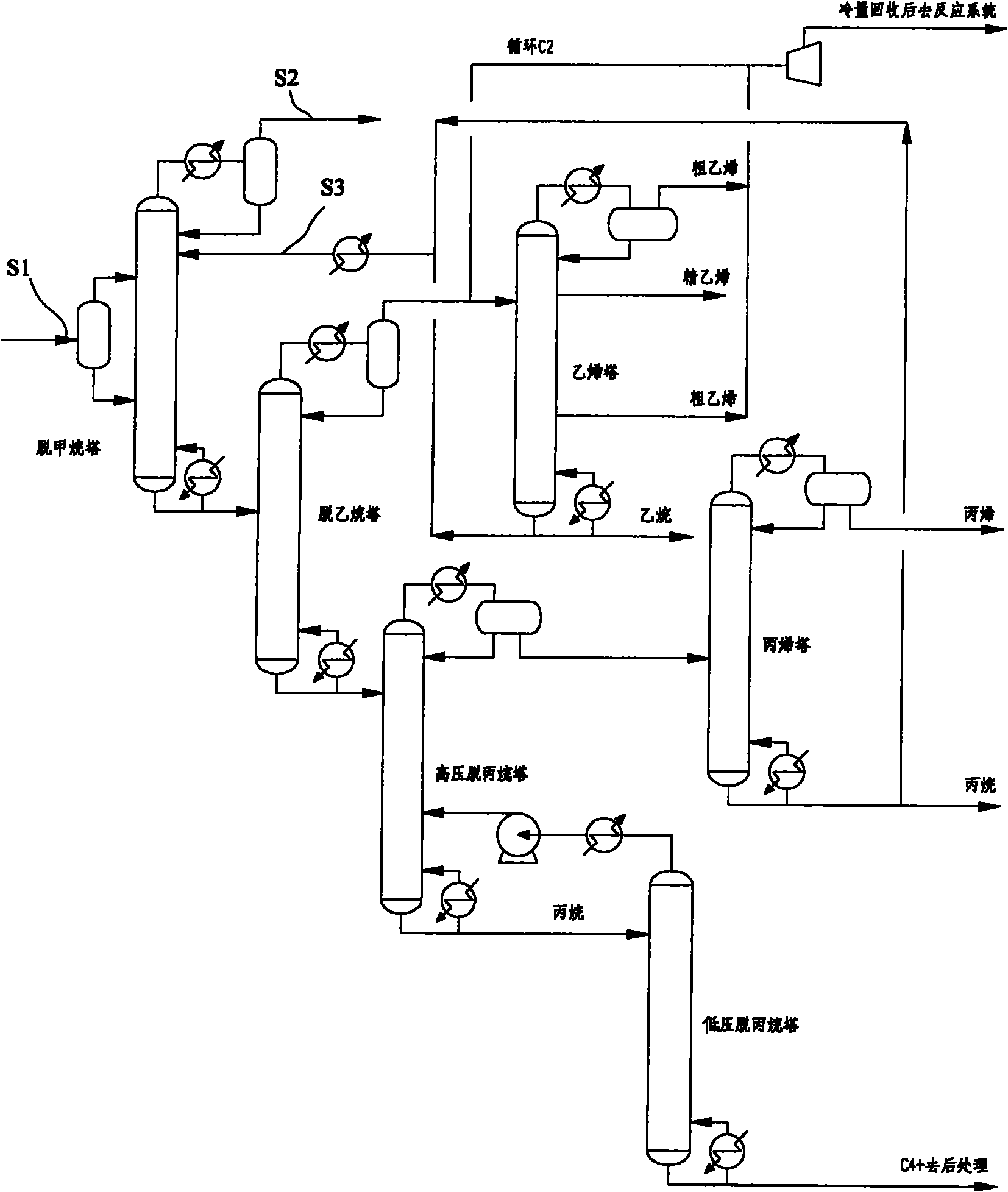

[0044] Such as image 3 , the low-carbon hydrocarbons from the reaction are cooled after quenching, compression and impurity removal. Under the conditions of 3.2MPa and -30°C, they first enter the demethanizer feed separation tank for gas-liquid separation. The demethanizer uses ethane and propane The mixture is used as the absorbent, and the temperature of the absorbent is -20°C. The top of the demethanizer is CH 4 、H 2 , CO and N 2 Light components such as light components and partially lost ethane and propane absorbents, C2+ components at the bottom of the tower, directly enter the deethanizer. Part of the C2 at the top of the deethanizer goes to the ethylene tower, and part of it is recycled to the reaction system, and the C3+ at the bottom of the deethanizer enters the depropanizer. Refined ethylene is extracted from the side line of the ethylene tower, crude ethylene is extracted from the top and side line of the tower, and part of the C2 extracted from the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com