Method for processing mother solution of glyphosate

A glyphosate mother liquor and treatment method technology, applied in the field of acid mother liquor treatment, can solve the problems of incomplete recovery of mother liquor, waste of materials, increased production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

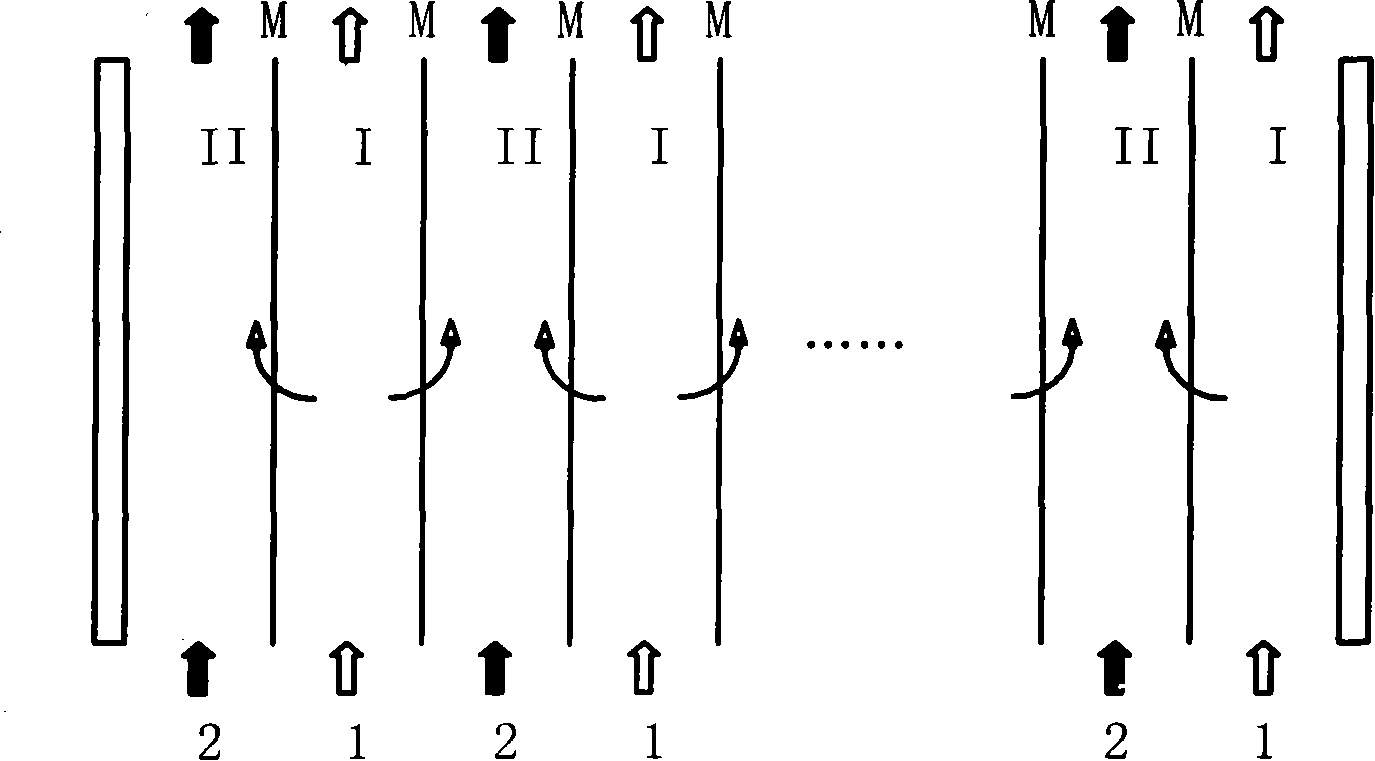

[0069] The glyphosate mother liquor obtained when glyphosate is produced by the dialkyl phosphite method contains about 23.5% hydrochloric acid, about 20% triethylamine, and about 3% glyphosate. Take such glyphosate mother liquor 1000ml into such as figure 1 The raw solution chamber I of the diffusion dialysis device, which is composed of recovery chamber II-diffusion dialysis membrane M-stock solution chamber I-diffusion dialysis membrane M in sequence and repeatedly, 3000ml of pure water enters the recovery chamber II, after 24 hours of diffusion dialysis, The recovery room obtains 1700ml concentration of hydrochloric acid of 0.98mol / L, and the recovery rate of hydrochloric acid is about 24%. The glyphosate mother liquor that stoste room obtains is 2300ml, and the pH value is about 0.96, is neutralized to about pH value about 11 with 30% sodium hydroxide solution, consumes 530ml of 30% sodium hydroxide solution altogether, leaves standstill layering, Recover about 310ml of ...

Embodiment 2

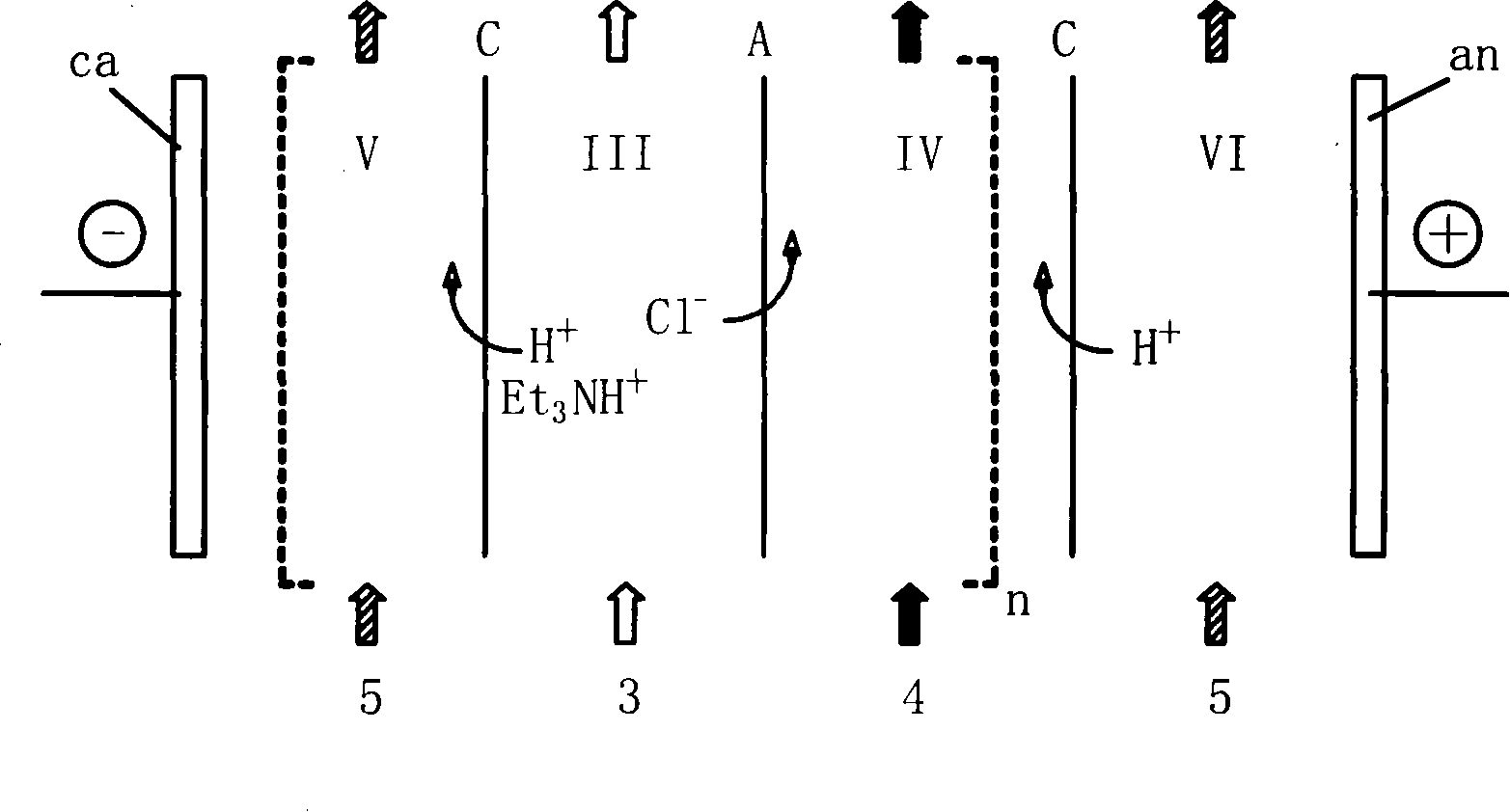

[0071] 1000ml glyphosate mother liquor enters such as image 3 The dilute electrodialysis device shown is composed of cathode chamber V-anion exchange membrane A-dilute chamber III-anion exchange membrane A-concentrated chamber IV-cation exchange membrane C-anode chamber VI and cathode ca and anode an on both sides. In chamber III, 1500ml of hydrochloric acid solution with a concentration of about 0.3mol / L enters concentrated chamber IV, the anolyte is 1mol / L sulfuric acid solution, and the catholyte is 1mol / L sodium hydroxide solution. 2 The electric current density electrodialysis is 78 hours, and the pH of the solution in the dilute chamber is about 9.5. It is 1.93mol / L hydrochloric acid that 2500ml concentration is recovered in the concentrated chamber, the recovery rate of hydrochloric acid is about 62.8%, and the average current efficiency is 35.7%. Obtain 1400ml of glyphosate mother liquor in the light room, neutralize it with 30% sodium hydroxide solution until the pH...

Embodiment 3

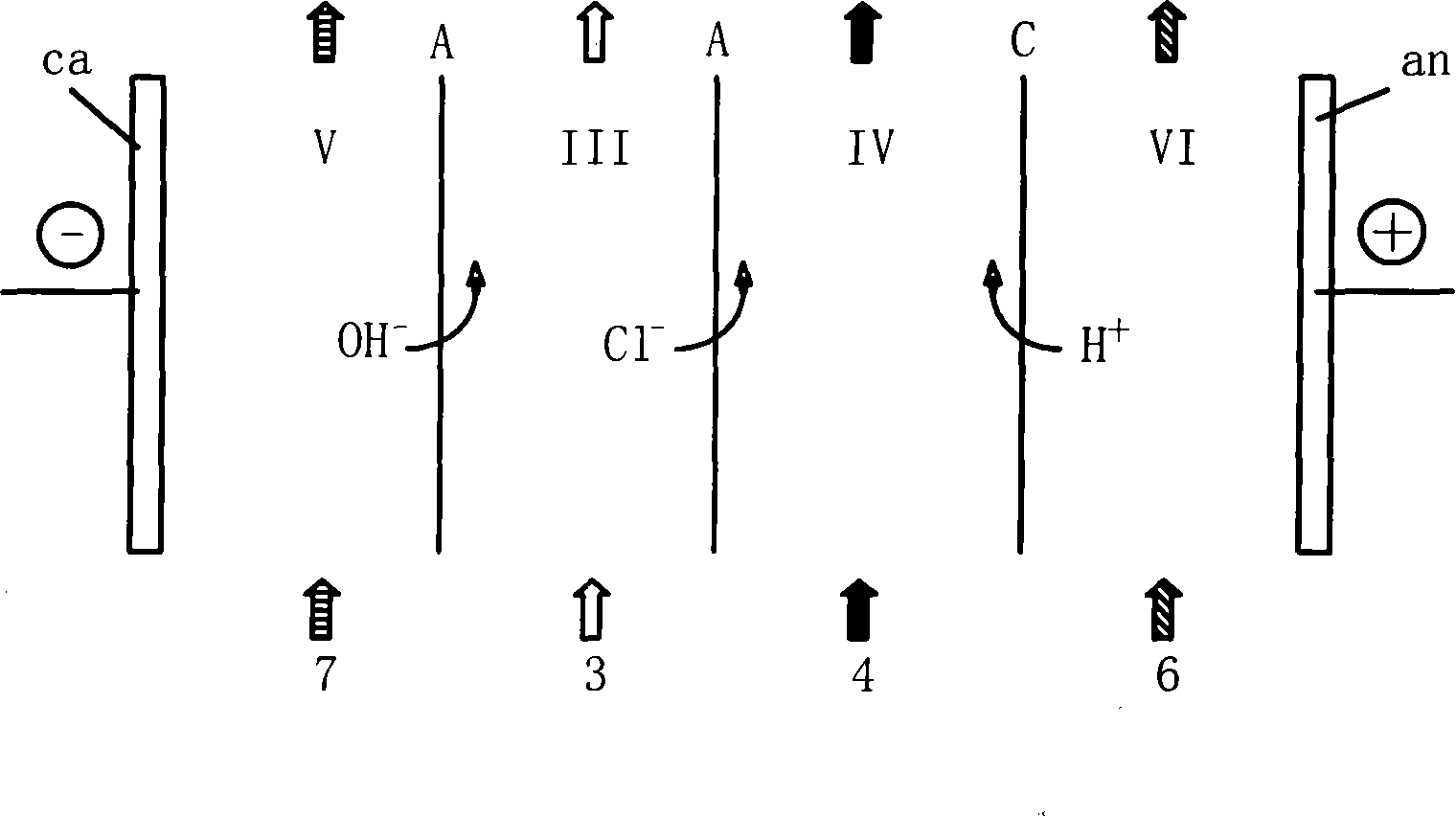

[0073] 1000ml glyphosate mother liquor enters such as Figure 4The dilute electrodialysis device shown is composed of cathode chamber V-cation exchange membrane C-dilute chamber III-anion exchange membrane A-concentrated chamber IV-cation exchange membrane C-anode chamber VI and cathode ca and anode an on both sides In chamber III, 1500ml of hydrochloric acid solution with a concentration of about 0.3mol / L enters concentrated chamber IV, the anolyte is 1mol / L sulfuric acid solution, and the catholyte is 1mol / L sodium hydroxide solution. 2 Electrodialysis at a high current density for 110 hours until the pH of the solution in the dilute chamber is about 2.3. It is 2.30mol / L hydrochloric acid that recovery to 3000ml concentration is 2.30mol / L in the concentration room, the recovery rate of hydrochloric acid is about 92.2%, and the average current efficiency is 32.1%. The catholyte was allowed to stand for stratification, and 220ml of triethylamine in the upper layer was separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com