Separating method and equipment of low-carbon olefins beneficial to product recovery

A technology for recovery of low-carbon olefins and products, which is applied in the purification/separation of hydrocarbons, adsorption purification/separation, chemical instruments and methods, etc., and can solve the problems of driving, parking inconvenience, significant cooling cycle energy consumption, and increased separation energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

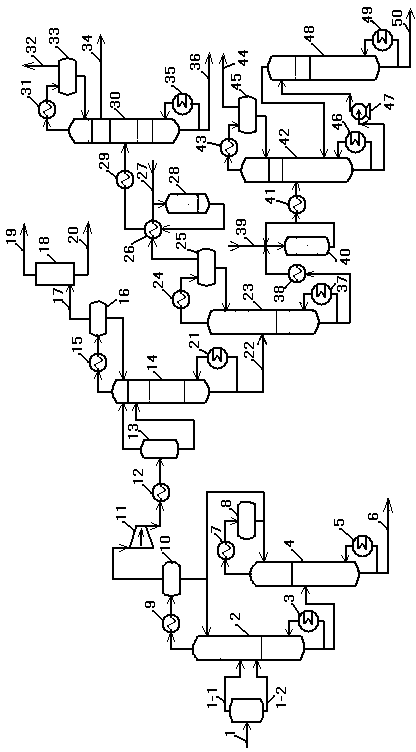

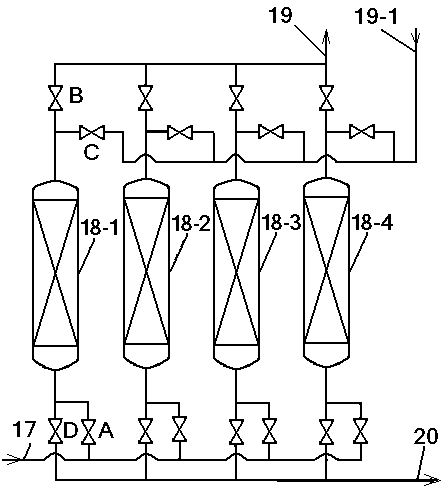

[0077] Such as figure 1 and figure 2 As shown, a low-carbon olefin separation method that is beneficial to product recovery, oxygenates are catalytically converted to produce a mixed gas of low-carbon olefins, and after the oxygenates and water are removed during pretreatment, in addition to ethylene and propylene, there is also Including one or more of hydrogen, oxygen, nitrogen, carbon monoxide, carbon dioxide, methane, ethane, acetylene, propane, cyclopropane, propyne and propadiene. The mixed material is compressed and heat-exchanged as a low-carbon olefin stream 1, which is divided into two phases of vapor and liquid, wherein the vapor phase passes through the pipeline 1-1, and the liquid phase enters the high-pressure depropanizer 2 through the pipeline 1-2, and the high-pressure depropanizer The tower bottom reboiler 3 is heated by steam so that the tower bottom product 6 enters the low-pressure depropanizer 4 for separation of C3 and C4. The butane tower system is ...

Embodiment 2

[0090] The difference between Example 2 and Example 1 is that the numerical parameters involved are: the operating pressure at the top of the high-pressure depropanizer is 1.8MPa, and the bottom temperature of the high-pressure depropanizer is 100°C; The operating pressure at the top of the tower is 0.5MPa, and the temperature at the bottom of the low-pressure depropanizer is 100°C; the operating pressure at the top of the demethanizer is 3.5MPa; the temperature at the top of the demethanizer is -45°C; the temperature at the top of the demethanizer is -45°C; The temperature at the bottom of the tower is -5°C, and the tower kettle is heated by circulating water; the pressure swing adsorbent is modified activated carbon loaded with copper, the adsorption pressure is 3.5MPa, and the adsorption temperature is -5°C; the deethanizer The operating pressure at the top of the tower is 2.0MPa; the temperature of the bottom of the deethanizer tower is 20°C; the operating pressure at the t...

Embodiment 3

[0092] The difference between embodiment 3 and embodiment 1 is that the numerical parameters involved are: the operating pressure at the top of the high-pressure depropanizer is 3.8MPa, and the temperature at the bottom of the high-pressure depropanizer is 20°C; The operating pressure at the top of the tower is 1.5MPa, and the temperature at the bottom of the low-pressure depropanizer is 20°C; the operating pressure at the top of the demethanizer is 4.0MPa; the temperature at the top of the demethanizer is -43°C; the temperature at the top of the demethanizer is -43°C; The temperature at the bottom of the tower is 45°C, and the tower kettle is heated by circulating water; the pressure swing adsorbent is modified activated carbon loaded with copper, the adsorption pressure is 3.0MPa, and the adsorption temperature is 50°C; the top of the deethanizer is The operating pressure is 3.3MPa, and the temperature of the deethanizer tower is 100°C; the operating pressure at the top of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com