Method for preparing zinc oxide hollow spheres

A hollow sphere, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, can solve the problems of energy consumption, little research on the application of hollow spheres, time-consuming synthesis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Zinc acetate, dimethyl sulfoxide and water were used as raw materials to synthesize graded zinc oxide hollow spheres by ultrasonic irradiation. Weigh 1.098g of zinc acetate into a 100ml beaker, add 47.5ml of dimethyl sulfoxide, and then add 2.5ml of water, put the probe of the ultrasonic cell disruptor into the beaker, and adjust its power to 300W, set the ultrasonic The mode is 8s, and the time is 1h. After the ultrasound is finished, the white precipitate is collected by centrifugation, and washed with water and alcohol for 3 times each. Dry at 60°C.

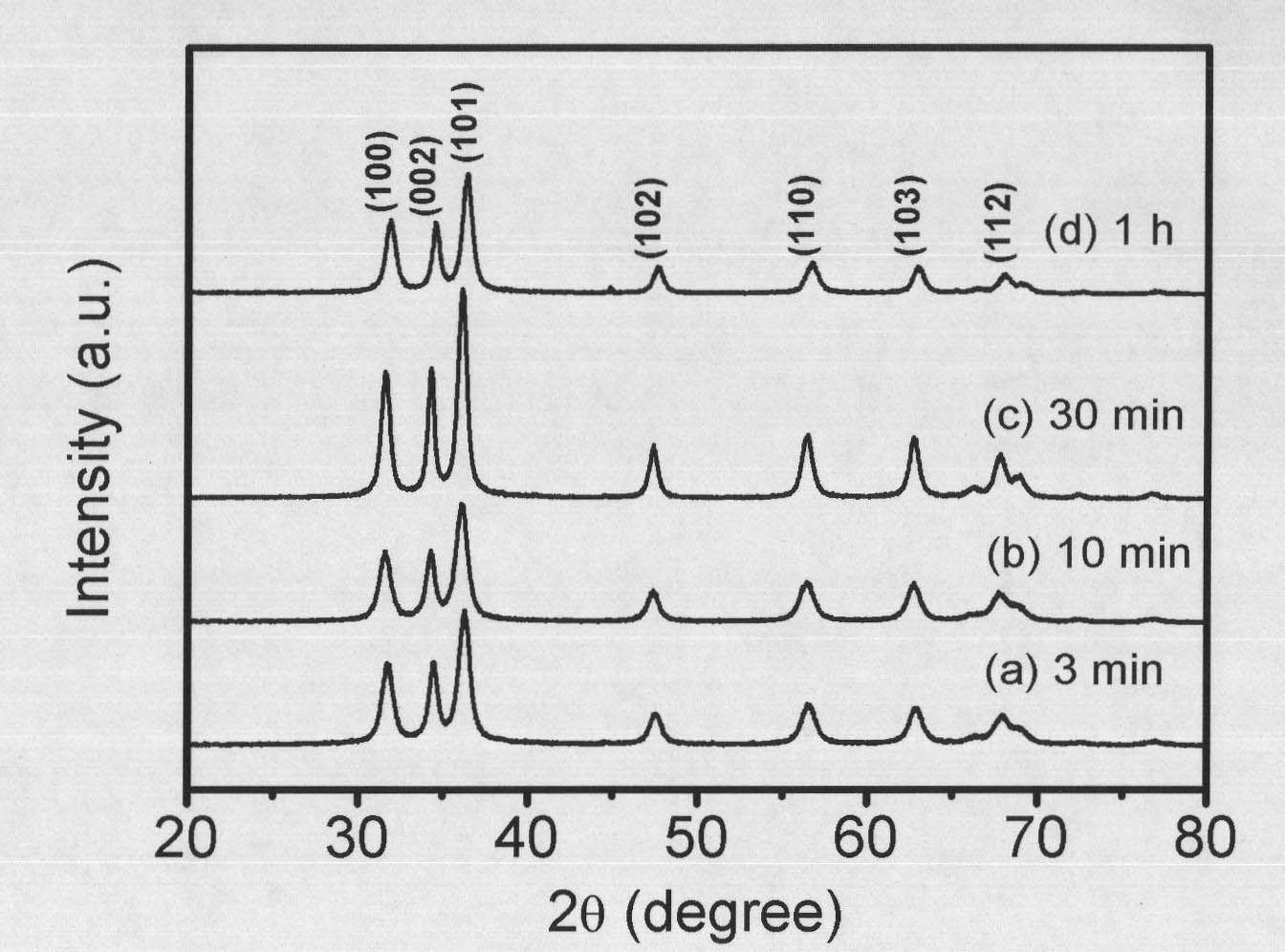

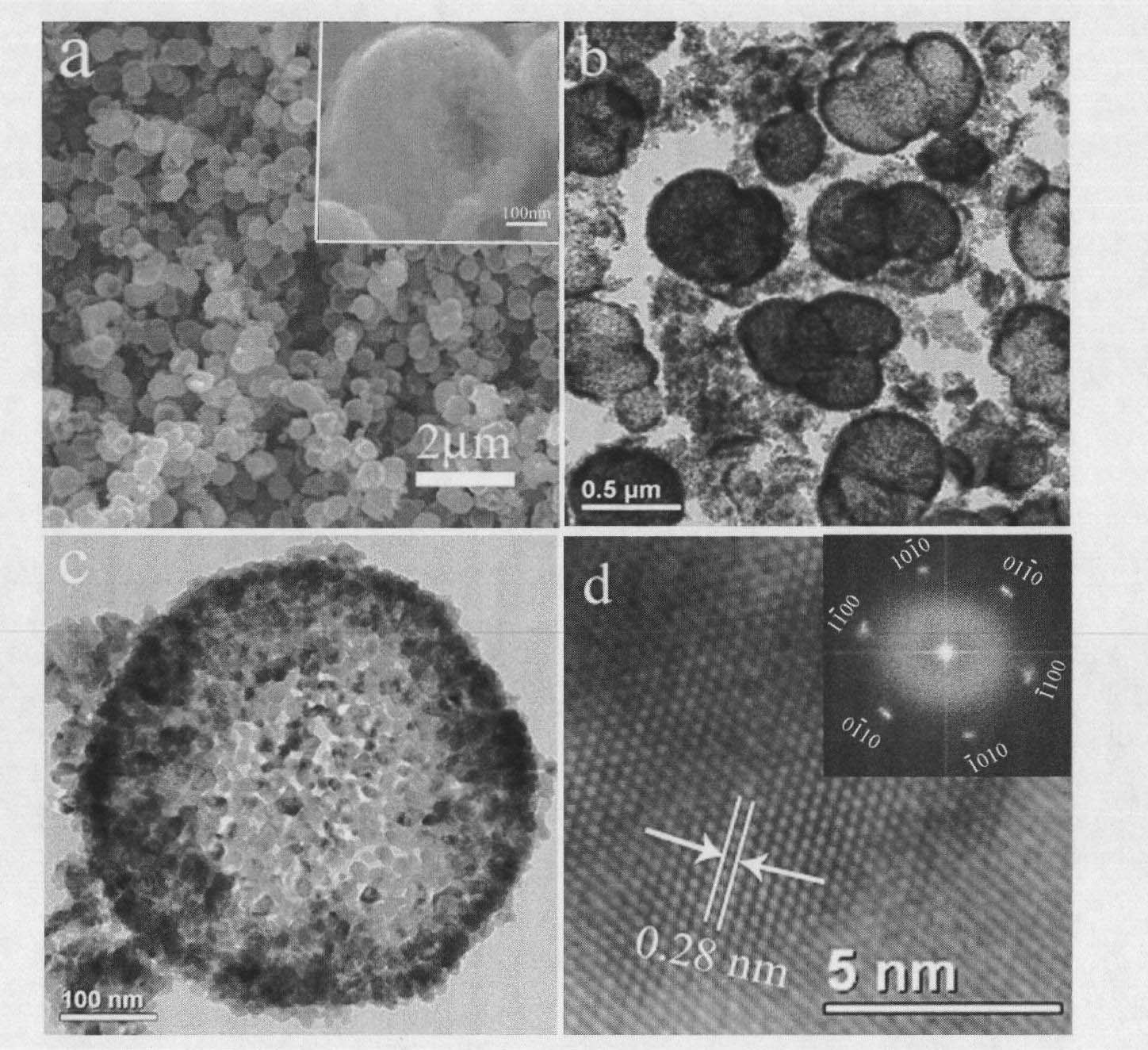

[0027] White powder after drying is directly used for XRD test, judges its crystalline form, the result finds that prepared zinc oxide is a wurtzite structure (see figure 1 ), observe its morphology with a scanning electron microscope, and measure its morphology and crystal structure with a transmission electron microscope ( figure 2 ), found that submicron-sized hierarchical ZnO hollow spheres were composed of nanop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com