Cake surface sesame scattering machine

A technology of sesame machine and sesame, which is applied in the fields of dough processing, baking, food science, etc., to achieve the effect of being conducive to cleaning, quick and even distribution of sesame seeds, and less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

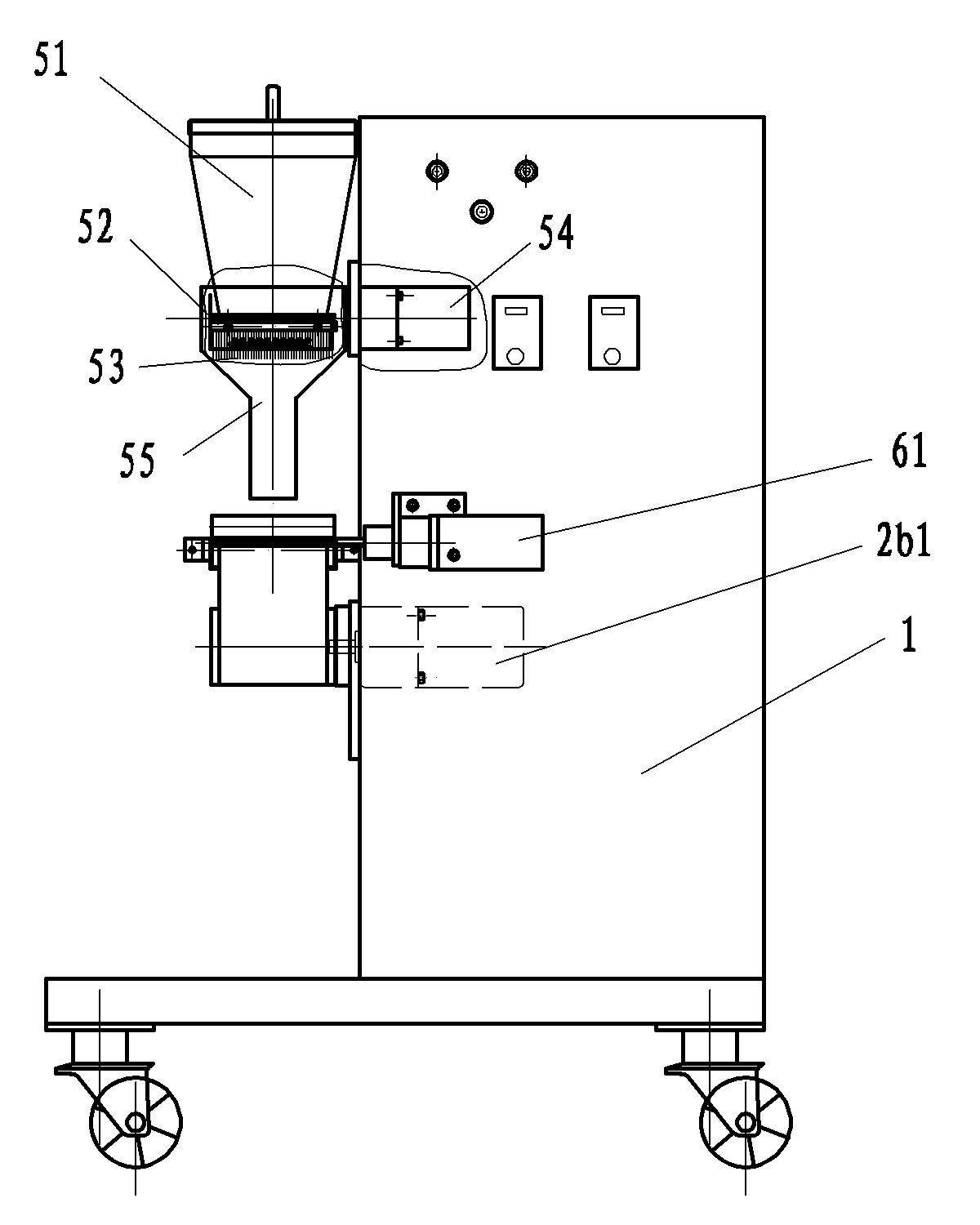

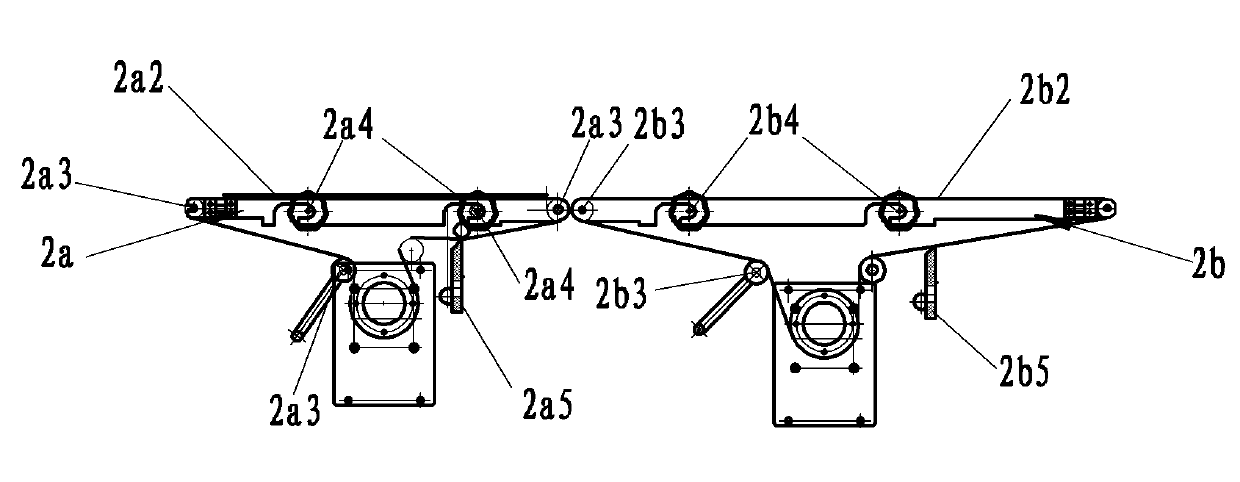

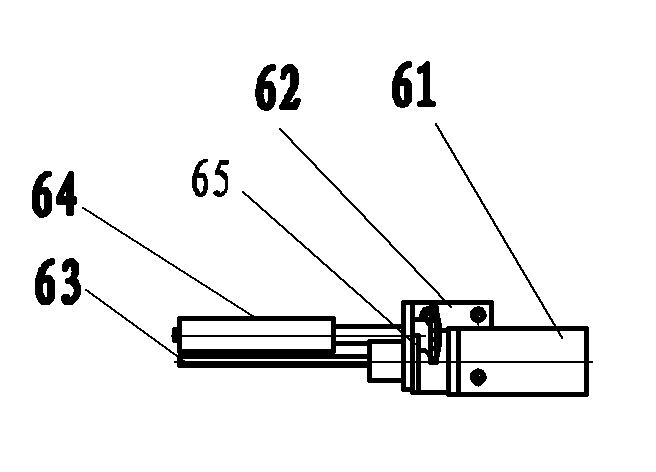

[0023] Such as figure 1 to Figure 11 As shown in , the cake surface sprinkler of the present invention comprises a body 1, a cake importing and conveying mechanism 2, a cake surface spraying mechanism 3, a slurry mist suction mechanism 4, a cake surface spreading sesame mechanism 5, and a cake pressing mechanism. Mechanism 6, the cake importing conveying mechanism 2 is formed by docking the conveying mechanism 2a of the cake spraying section and the conveying mechanism 2b of the cake spreading sesame. Roller 2a4, 2b4, scraper 2a5, 2b5 constitute, cake surface spraying slurry mechanism 3 is made of slurry storage tank 31, slurry delivery pipe 32, nozzle 33, slurry mist suction mechanism 4 is composed of slurry mist suction pipe 41, filter 42, vacuum pump 43. The slurry mist cover 44 is formed. The cake surface sprinkler mechanism 5 is composed of a sesame storage hopper 51, a sesame distributor 52, a brush 53, a motor 54, and a sesame bucket 55. The cake sugar spraying secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com