A cold-shear shearing device and shearing process for finish-rolled rebar

A technology of precision-rolled rebar and shearing device, which is applied in the field of rebar, can solve the problems of easy bending, unsmooth feeding, and long time consumption, and achieve the effects of ensuring feeding, reducing arrangement time, and improving support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

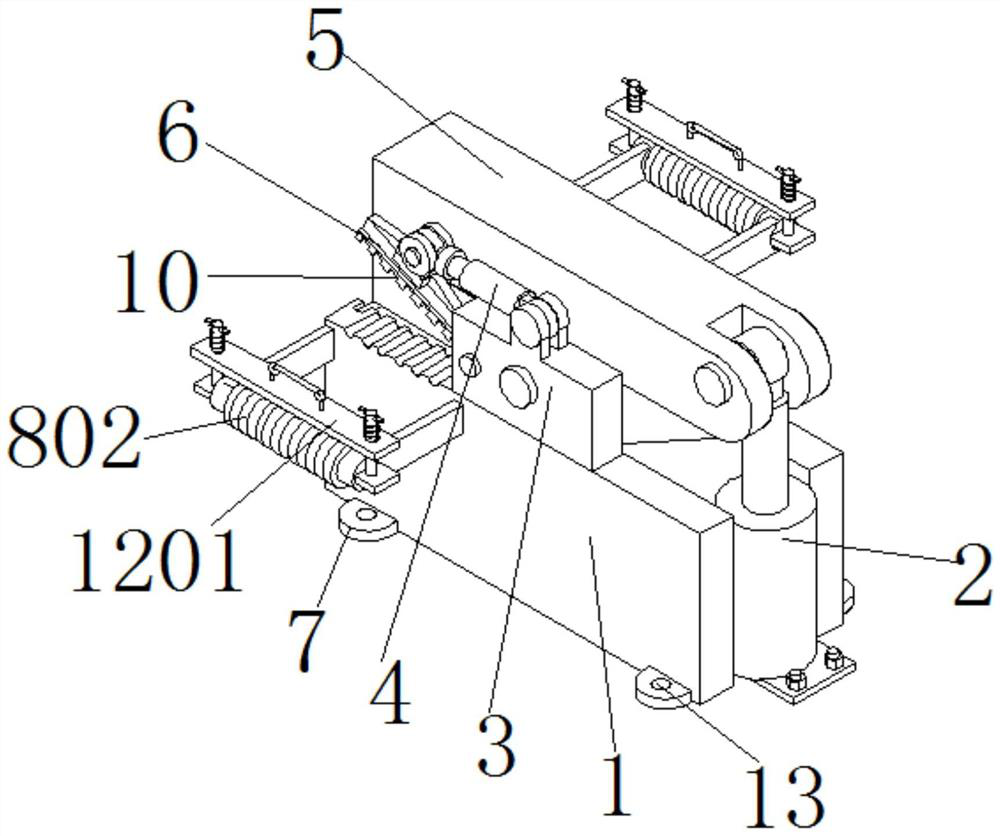

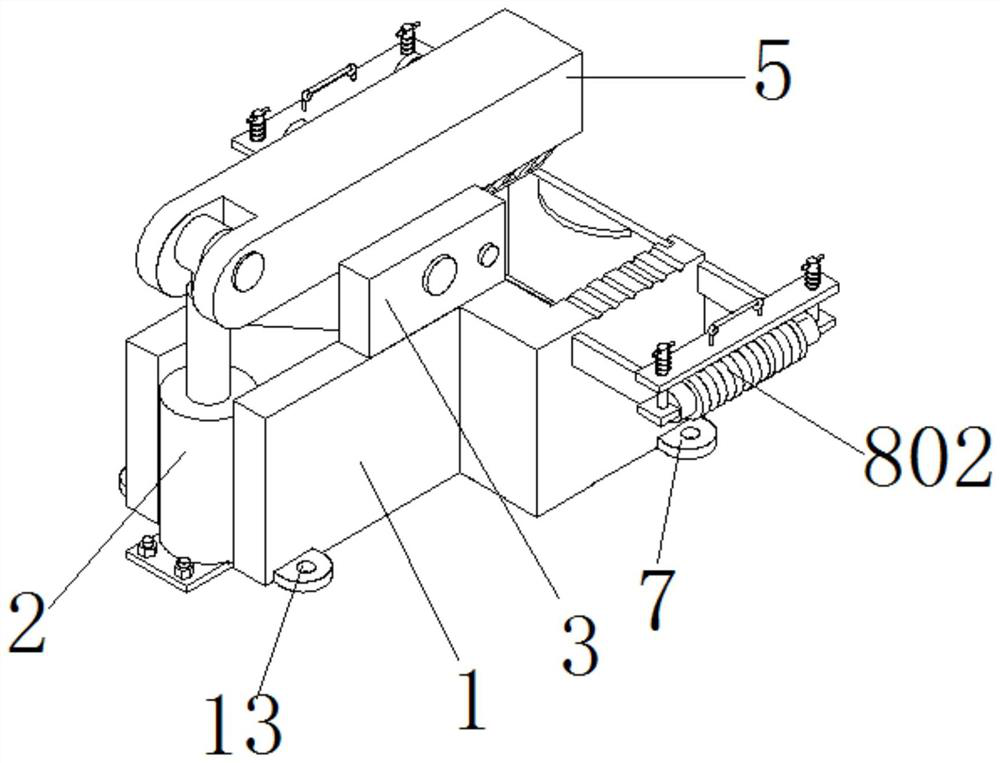

[0042] Embodiment 1 has introduced a kind of finish-rolled rebar cold shear shearing device and shearing process, as Figure 1-3 As shown, it includes a base 1, an electric telescopic rod one 2, a support seat 3, an electric telescopic rod two 4, a shear knife 5 and a fixed arm 6, and the shearing device also includes a fixed foot 7, an auxiliary support assembly 8 and a rebar Storage component 9;

[0043] There is a pair of bases 1, and a support base 3 is fixedly connected to the central position of the upper surface of a pair of bases 1, and the shearing knife 5 is connected to a pair of support bases 3 in rotation, and the support base 3 Rotationally connected to the middle position of the shearing knife 5; one end of the shearing knife 5 is rotationally connected to the top of the electric telescopic rod-2, and the bottom end of the electric telescopic rod-2 is fixedly connected to the ground through a connecting plate and bolts On: the upper surface of the support base ...

Embodiment 2

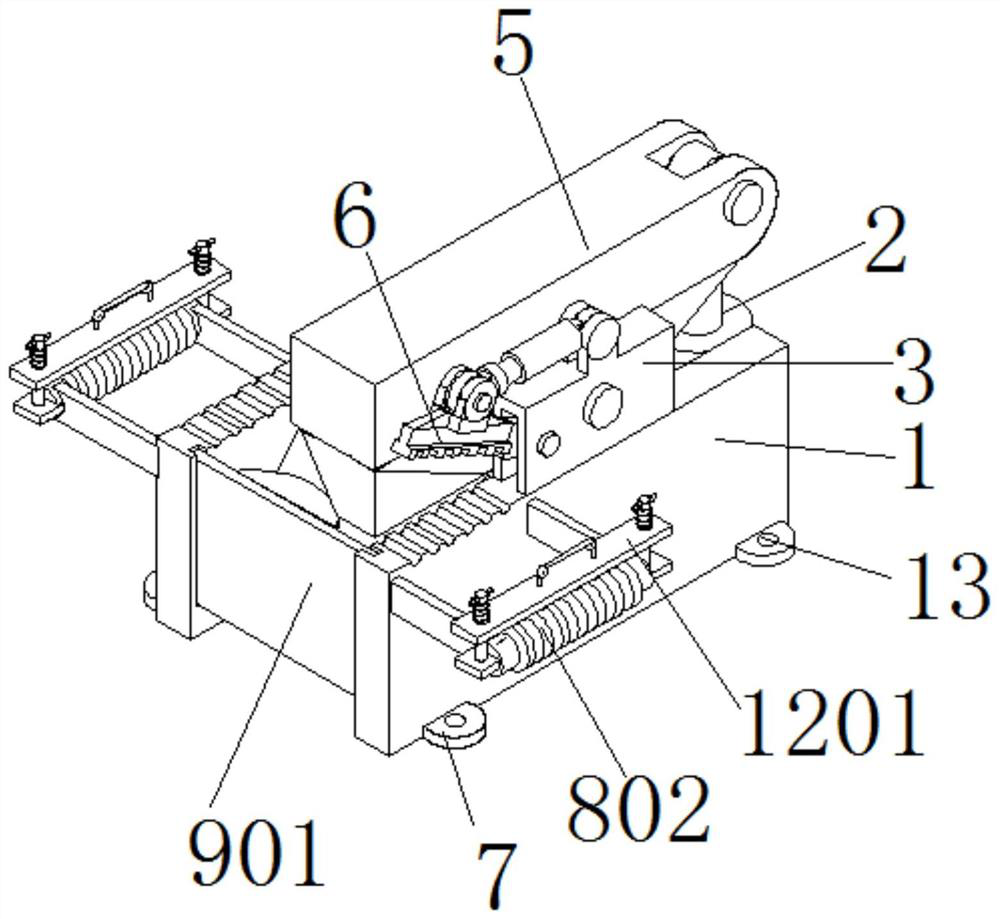

[0054] Embodiment 2 is an improvement on the basis of Embodiment 1, as Figure 7-8 As shown, wherein, a pair of the bases 1 are equipped with a threaded steel storage assembly 9, and the threaded steel storage assembly 9 includes a collection slope 901 and a baffle 902, and the two sides of the collection slope 901 are respectively fixedly connected to On the side of a base 1; a pair of inner sides of the base 1 are provided with a vertical chute 903, and the chute 903 extends vertically downward from the upper surface of the base 1 to the collection swash plate 901. The two sides of the baffle plate 902 are respectively snapped into a chute 903 and the baffle plate 902 can slide freely in the vertical direction along the chute 903; The top surface of the baffle plate 902 is in close contact with;

[0055] In this embodiment, the present invention can collect the cut threaded steel waste by setting the collecting inclined plate and the baffle plate 902. The baffle plate 902 i...

Embodiment 3

[0062] Embodiment 3 is an improvement on the basis of Embodiment 2, as Figure 9-10 As shown, the lower surface of the limiting plate 1201 is fixedly connected with several limiting protruding blocks 17 , and each of the limiting protruding blocks 17 is located directly above a limiting groove 3 16 .

[0063] In this embodiment, the lower surface of the limiting plate 1201 is fixedly connected with a number of limiting protruding blocks 17 and the limiting protruding blocks 17 are in one-to-one correspondence with the limiting groove three 16. The threaded steel is fixed, so that the threaded steel is stably engaged in the third limiting groove 16.

[0064] Embodiment 3 provides a shearing process for finishing-rolled rebar cold shear shearing device shearing finish-rolled rebar, and the shearing process includes the following steps:

[0065] Step 1, conveying the rebar to the auxiliary support roller 802 through the conveyor belt;

[0066] Step 2, the rebars are evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com