Method for comprehensively recovering anode materials of waste lithium ion batteries

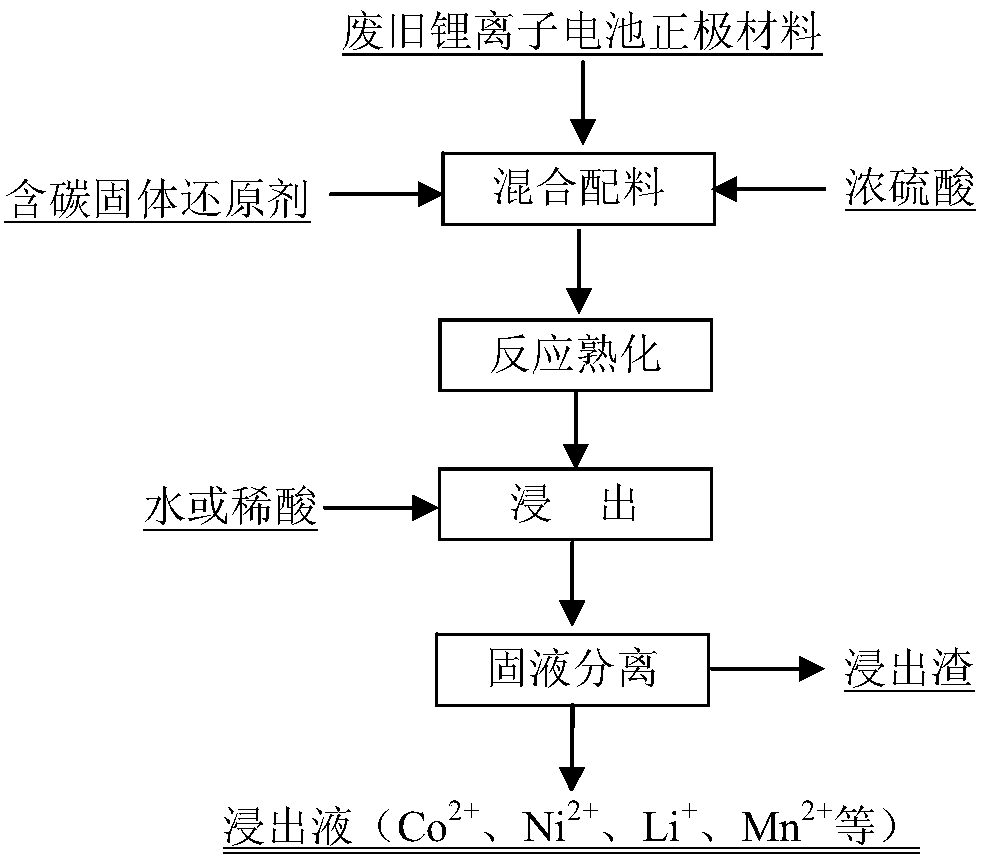

A lithium-ion battery and cathode material technology, which is applied in the field of comprehensive recovery of useful elements in waste lithium-ion battery cathode materials, can solve the problems of high equipment requirements, increased energy consumption and cost, and achieve reduced energy consumption, fast response, and reduced costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Get 100g of ternary battery cathode powder containing 10.63% cobalt, 6.50% lithium, 28.30% nickel, 11.75% manganese, and 3.75% iron, and mix it evenly with concentrated sulfuric acid with a mass concentration of 98% and anthracite coal powder with a fixed carbon content of 75%. The amount of concentrated sulfuric acid added is the total molar ratio of sulfuric acid to all metal elements in the positive electrode material 2:1, and the amount of anthracite powder added is the total molar ratio of the total carbon in the coal powder to all metal elements in the positive electrode material 1:2; After the material was stirred evenly, it was reacted and matured at 300°C for 2 hours, and the obtained matured material was soaked in water for 1 hour at 95°C and a liquid-solid ratio of 5:1mL / g. The composition is charcoal leaching residue, the leaching rate of cobalt is 99%, the leaching rate of lithium is 99%, the leaching rate of nickel is 98%, the leaching rate of manganese is ...

Embodiment 2

[0032] Take 100g of positive electrode powder containing 51.78% cobalt, 6.14% lithium, and 8.30% aluminum, and mix it evenly with concentrated sulfuric acid with a mass concentration of 98% and anthracite powder with a fixed carbon content of 75%. The total molar ratio of all metal elements is 2:1, and the amount of anthracite powder added is the total molar ratio of the total carbon in the coal powder to the total molar ratio of all metal elements in the positive electrode material; after the mixture is stirred evenly, it is reacted and matured at 250°C for 2 Hours, the obtained clinker was immersed in water for 1 hour at 95°C and a liquid-solid ratio of 8:1mL / g, and the solid-liquid separation obtained a solution containing cobalt, nickel, and lithium ions. The leaching solution was further purified and separated to recover nickel, cobalt, and lithium.

Embodiment 3

[0034] Take 100g of ternary battery positive electrode powder containing 4.95% cobalt, 2.99% lithium, 12.39% nickel, 17.01% manganese, 1.53% iron, and 15% moisture, and combine it with concentrated sulfuric acid with a mass concentration of 98% and coke with a fixed carbon content of 85%. Mix the powder evenly, wherein the added amount of concentrated sulfuric acid is the total molar ratio of sulfuric acid to all metal elements in the positive electrode material 2:1, and the added amount of coke powder is the total molar ratio of the total carbon in the coke powder to all metal elements in the positive electrode material 1 : 1; after the mixed material was stirred evenly, it was reacted and matured at 250°C for 2 hours, and the obtained cured material was soaked in water for 1 hour at 95°C and a liquid-solid ratio of 6:1mL / g, and the solid-liquid separation obtained the compound containing cobalt, nickel, manganese, and lithium ions. The solution, the leaching solution is furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com