Biochemical anti-salt anti-high temperature oil displacement viscosity reducer and preparation method thereof

A technology of high temperature resistance and viscosity reducing agent, applied in the field of oil displacement viscosity reducing agent, can solve problems such as difficulties and immature technology, achieve convenient construction, improve crude oil recovery, high temperature resistance and salinity resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a biochemical anti-salt and anti-high temperature oil displacement viscosity reducer, the preparation method comprises the following steps:

[0039] ① Inoculate Pseudomonas aeruginosa ATCC NO.9027 on a solid medium and culture at 37°C for 1 day. The solid medium is agar powder 20g / L, glucose 10g / L, NH 4 Cl2g / L, K 2 HPO 4 3.5g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O0.2g / L, FeSO 4 ·7H 2 O0.1g / L, add water to 1L, pH is 7;

[0040] ②Transfer the single colony of the solid medium obtained in step ① into the seed medium, and shake and culture at 150rpm at 37°C for 2 days to obtain the seed liquid. The seed medium is glucose 10g / L, NH 4 Cl2g / L, K 2 HPO 4 12H 2 O3.5g / L, KH 2 PO 4 0.5g / L, KCl0.5g / L, MgSO 4 ·7H 2 O0.2g / L, FeSO 4 ·7H 2 O0.1g / L, add water to 1L, pH is 7;

[0041] ③Add the seed liquid obtained in step ② into the fermentation medium, and cultivate it at 37°C for 4 days to obtain a microbial fermentation liquid, the glucose 12g / L,...

Embodiment 2

[0045] A preparation method of a biochemical anti-salt and anti-high temperature oil displacement viscosity reducer, the preparation method comprises the following steps:

[0046] ① Inoculate Bacillus subtilis ATCC NO.21332 on a solid medium and culture at 37°C for 1 day. The solid medium is agar powder 20g / L, glucose 10g / L, NH 4 Cl2g / L, K 2 HPO 4 3.5g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O0.2g / L, FeSO 4 ·7H 2 O0.1g / L, add water to 1L, pH is 7;

[0047] ②Transfer the single colony of the solid medium obtained in step ① into the seed medium, and culture it with shaking at 150rpm for 2 days at 37°C to obtain the seed liquid. The seed medium is glucose 12g / L, NH 4 Cl1.5g / L, K 2 HPO 4 12H 2 O3.5g / L, KH 2 PO 4 0.5g / L, KCl0.5g / L, MgSO 4 ·7H 2 O0.2g / L, FeSO 4 ·7H 2 O0.2g / L, add water to 1L, pH is 7.5;

[0048] ③Add the seed liquid obtained in step ② into the fermentation medium, and cultivate it at 37°C for 4 days to obtain a microbial fermentation liquid, the glucose ...

PUM

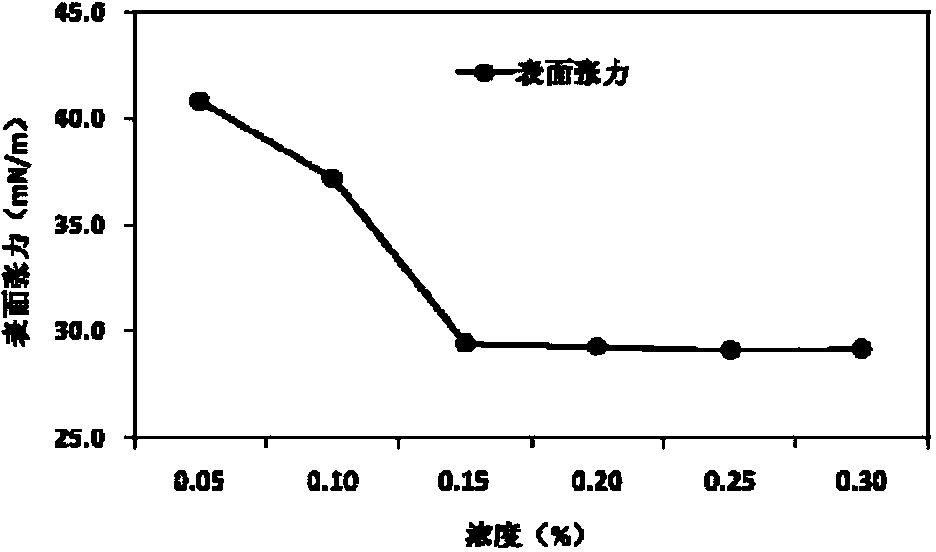

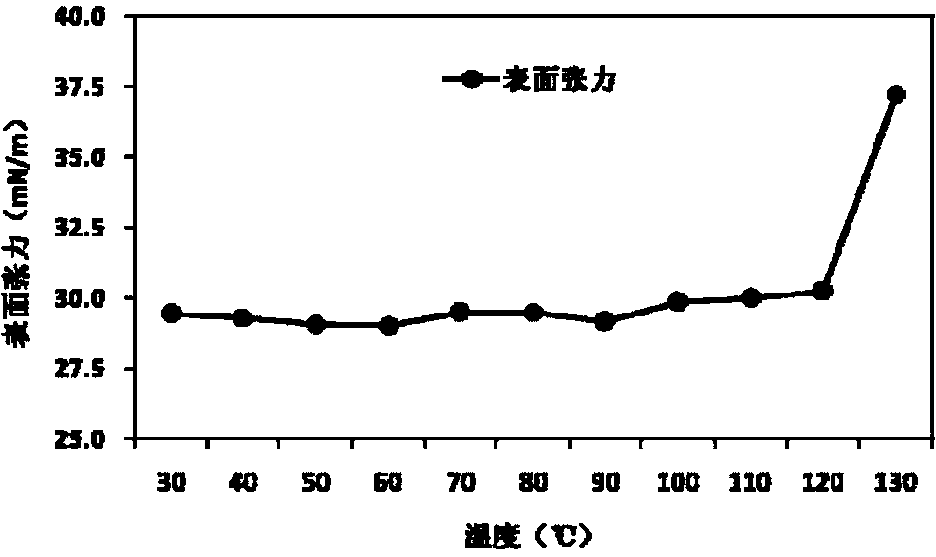

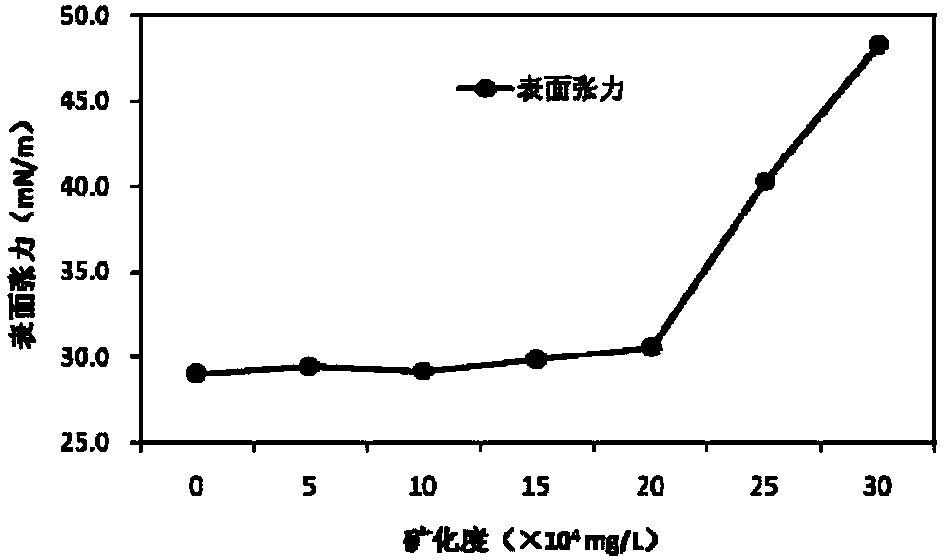

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com