High-temperature chain oil composition

A technology of high temperature chain and ester oil, applied in the field of lubricating oil, which can solve the problems of high volatility and low flash point of polyether

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

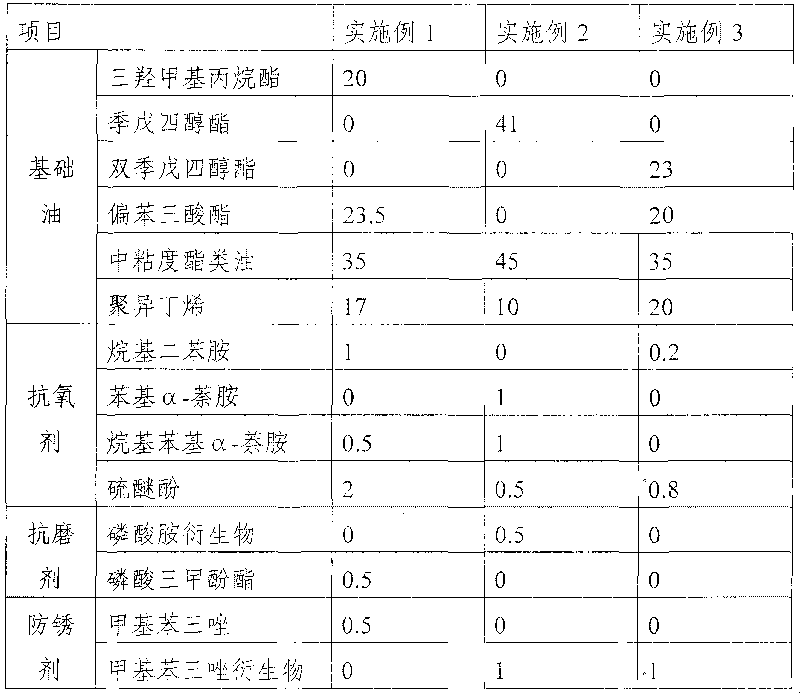

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0018] The production process of product of the present invention is example with 100kg test product, and production process is as follows:

[0019] Add about 30kg of low-viscosity ester oil base oil into the blending kettle, heat and stir to 100-120°C, add antioxidant and keep stirring for 30 minutes until the antioxidant is completely dissolved; add medium-viscosity ester oil and polyisobutylene, keep stirring 30 minutes until the solution is homogeneous and transparent; add the remaining amount of low-viscosity ester oil, add other additives at 80-90°C, and stir for 1 hour until the rust inhibitor and anti-wear agent are evenly dispersed. Filter the finished product with a 100-mesh stainless steel strainer.

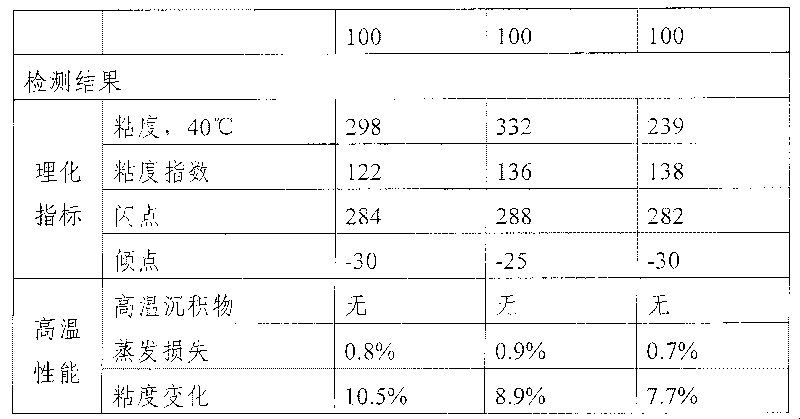

[0020] The physical and chemical indicators of the finished product are tested by the following methods: GB / T265 petroleum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com