Nylon composite material with low fuel oil permeability rate used for fuel oil tank and preparation method thereof

A nylon composite material, fuel permeability technology, used in gasoline drums, transportation and packaging, bicycle accessories, etc., can solve the problems of difficult and unsatisfactory fuel permeability, and achieve excellent gasoline barrier performance and good blow molding performance. , the effect of large market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

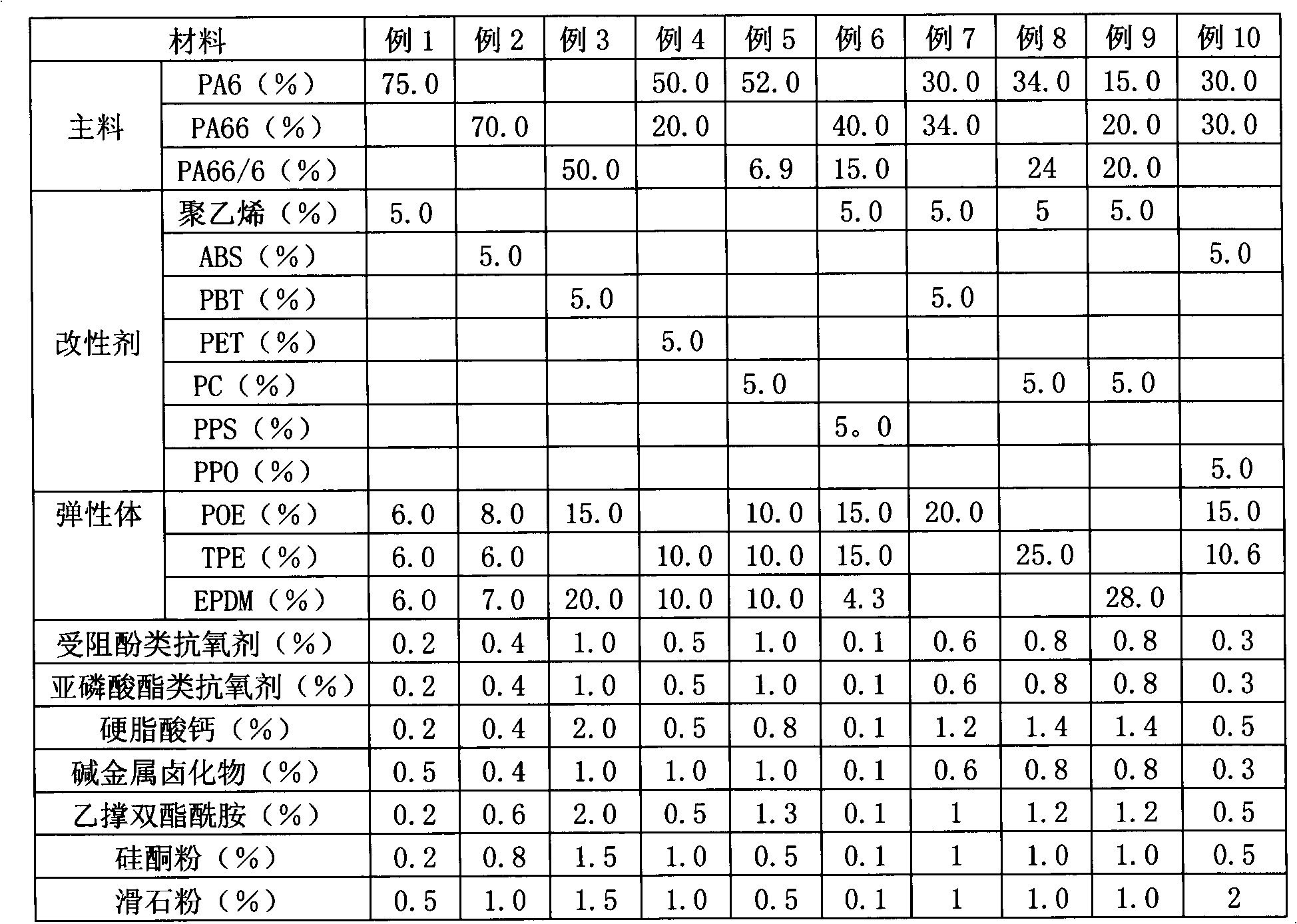

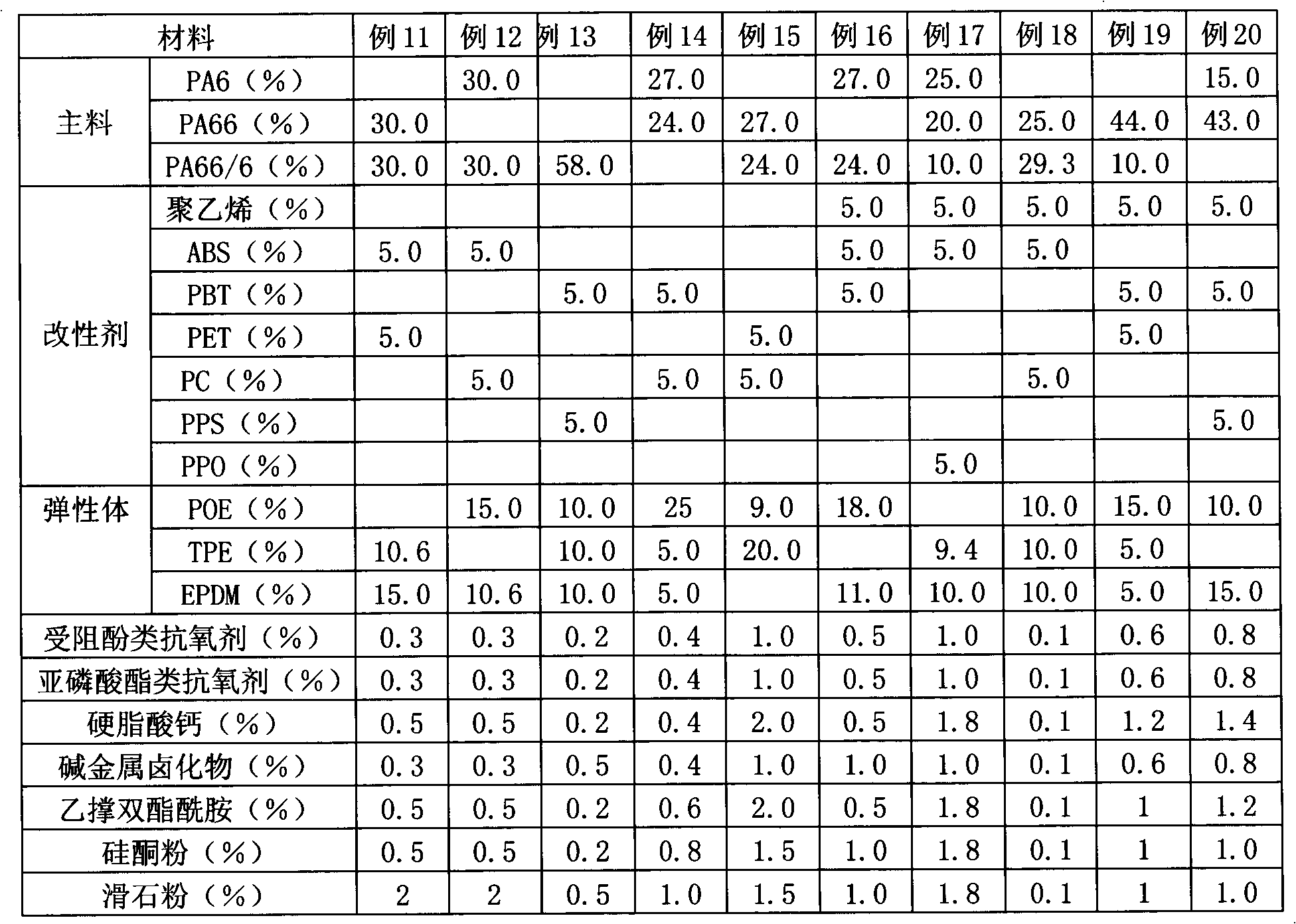

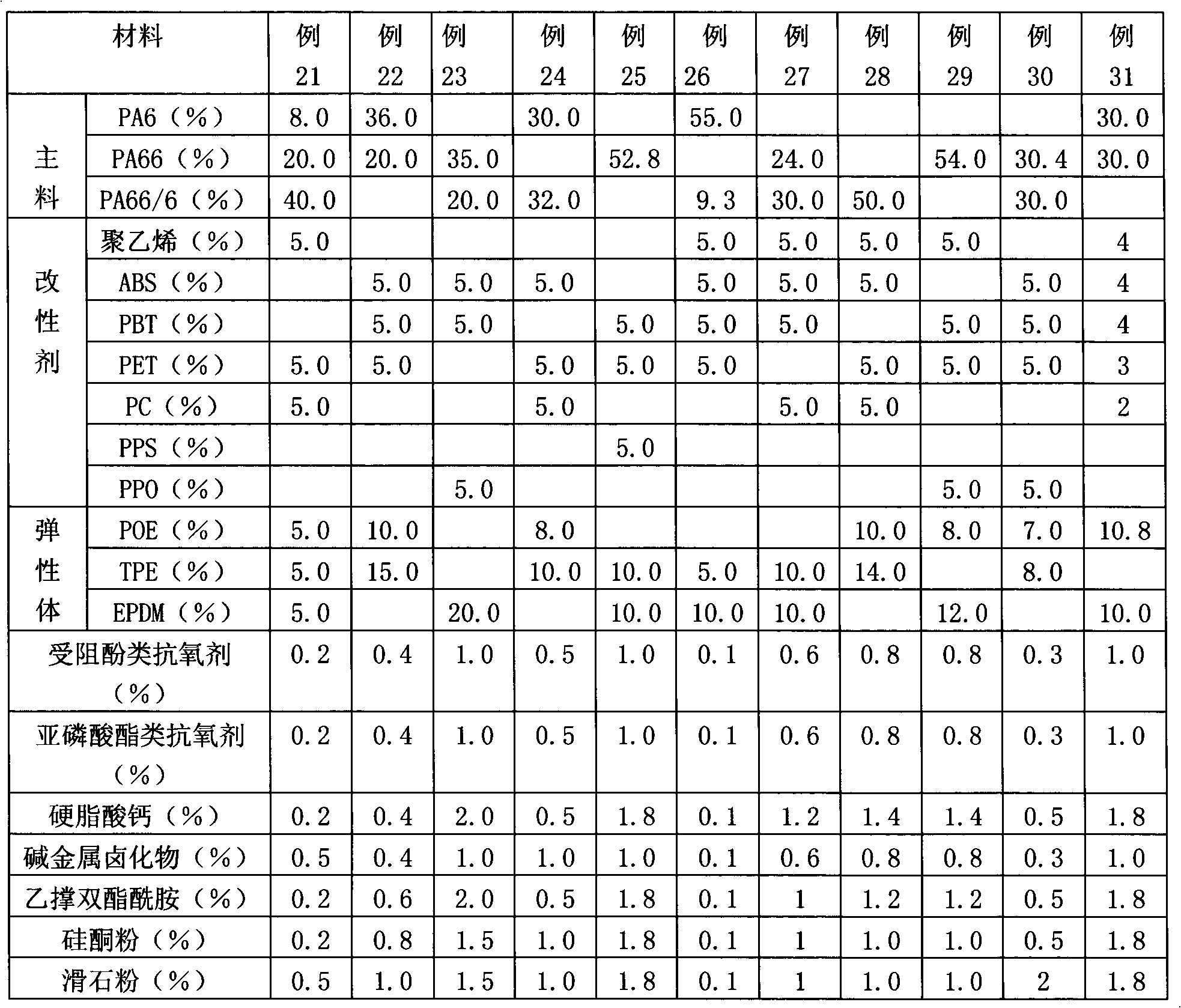

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

[0038]With the continuous improvement of environmental protection and safety requirements in various countries, countries around the world have continuously revised the evaporative emission indicators of vehicle fuel systems, and the requirements for the seepage resistance of plastic fuel tanks have become more and more stringent. For example, in Europe, the average fuel loss per fuel tank (40°C, 56 days) has been reduced from no more than 20 grams / 24 hours to 2 grams / 24 hours. "GB 20998-2007 Emission Limits and Measurement Methods of Fuel Evaporative Pollutants from Motorcycles and Mopeds" also puts forward a requirement of 2 g / 24 hours for vehicle emissions. In addition, the low-temperature impact resistance performance index required by vehicle gasoline fuel tank materials is very high. Although th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com