Nylon 6/graphene nanometer composite material with high thermal conductivity and preparation method thereof

A nano-composite material, graphene technology, applied in the field of high thermal conductivity nylon 6/graphene nano-composite material and its preparation, can solve the problems of reducing the performance of nylon 6 polymer material, low thermal conductivity, etc., and achieve good mechanical properties, The effect of high thermal conductivity and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

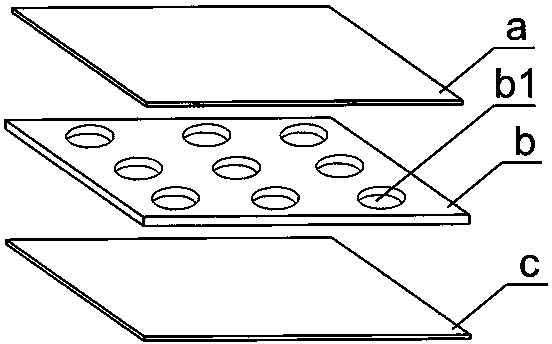

[0028] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

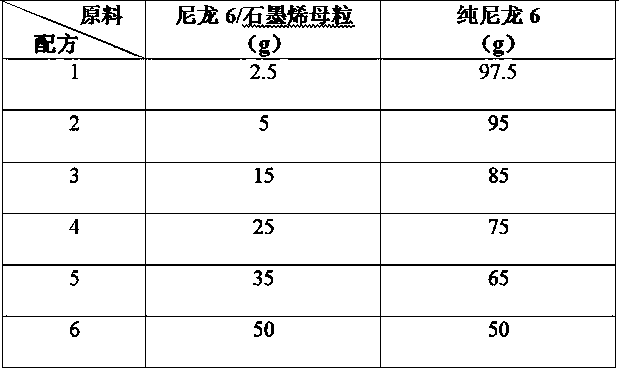

[0029] A kind of preparation method of high thermal conductivity nylon 6 / graphene nanocomposite material, comprises the steps:

[0030] Preparation of graphene oxide:

[0031] Take a 1000 ml three-neck bottle with 10 parts by weight of natural flake graphite and place it in an ice bath, add 400 parts by weight of 98% concentrated sulfuric acid dropwise, slowly add 30 parts by weight of potassium permanganate under continuous stirring, and prevent the temperature of the mixture from exceeding 20 °C , for 2 hours. The ice bath was removed, and the mixture was kept in a water bath at 35°C for 2 hours. Dilute the mixed solution with 600 parts by weight of deionized water, and keep the temperature of the mixed solution not higher than 90° C. for 15 minutes. Then dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com