Vehicle lamp

A technology for lamps and vehicles, which is applied to headlights, vehicle parts, lighting and heating equipment, etc., and can solve the problems of limited number of semiconductor light-emitting elements, insufficient road illumination, and inability to use array light sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

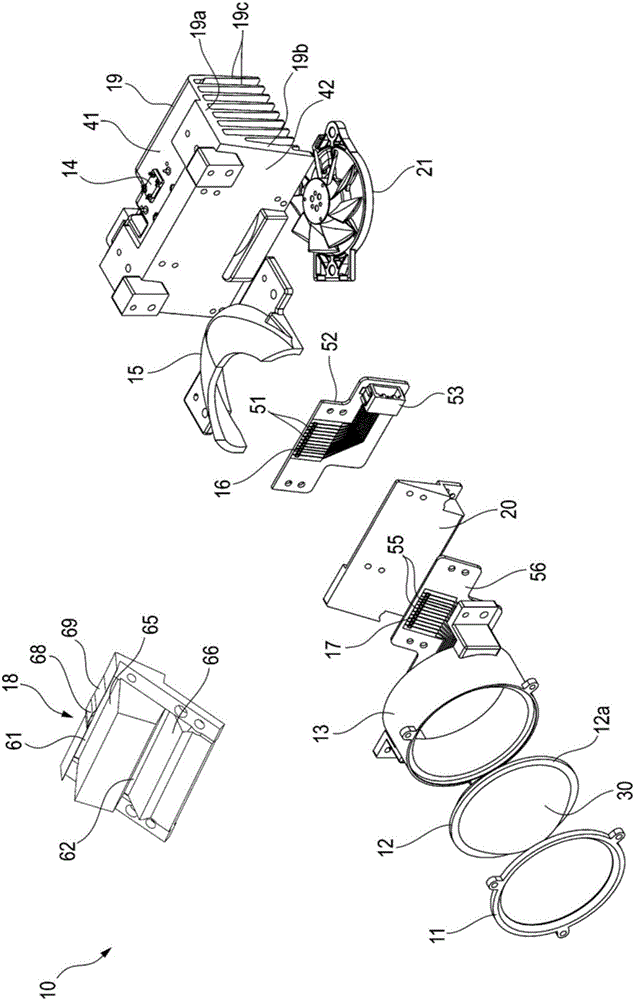

[0329] Such as Figure 12 As shown, in Modification 1, one rigid substrate 70 is provided. The rigid substrate 70 is, for example, a glass epoxy substrate or a paper phenol substrate. The rigid substrate 70 is fixed and attached to the second surface 42 which is an inclined surface of the base member 19 . On this rigid substrate 70 , the first array light source 16 and the second array light source 17 are mounted vertically at intervals. A connector 71 is provided on one side of the rigid substrate 70 . A connector (not shown) of a power supply line is connected to the connector 71 , and power is supplied from the power supply line to the semiconductor light emitting element 51 of the first array light source 16 and the semiconductor light emitting element 55 of the second array light source 17 .

[0330] According to such a configuration, it is easy to arrange the first array light source 16 and the second array light source 17 at predetermined positions with respect to th...

Deformed example 2

[0332] Such as Figure 13 and Figure 14 As shown, in Modification 2, one flexible substrate 80 is provided. The flexible substrate 80 is, for example, a substrate in which a wiring pattern 82 made of copper foil is formed on a highly flexible base 81 made of a plastic film such as polyimide. The flexible substrate 80 is fixed and mounted on the second surface 42 which is an inclined surface of the base member 19 . On this flexible substrate 80 , the first array light source 16 and the second array light source 17 are mounted vertically at intervals. On one side of the flexible substrate 80 , a lead-out portion 83 extends, and a connector 84 is provided on the lead-out portion 83 . A connector (not shown) of a power supply line is connected to the connector 84 , and power is supplied from the power supply line to the semiconductor light emitting elements 51 of the first array light source 16 and the semiconductor light emitting elements 55 of the second array light source 1...

Deformed example 3

[0337] Such as Figure 15 As shown, in Modification 3, there is a projection lens 90 in which the convex shape of the output surface is divided into upper and lower parts. Specifically, the projection lens 90 has a first lens portion 91 on the upper side and a second lens portion 92 on the lower side, and the first lens portion 91 and the second lens portion 92 are integrated. The first lens part 91 has a first incident surface 91a and a first output surface 91b, and the second lens part 92 has a second incident surface 92a and a second output surface 92b.

[0338] In Modification 3, the light L from the low beam light source 14 and the light LA1 from the first array light source 16 enter the first incident surface 91 a of the first lens portion 91 and are emitted from the first output surface 91 b. In addition, the light LA2 from the second array light source 17 enters the second incident surface 92 a of the second lens unit 92 and exits from the second exit surface 92 b.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com