Two-output-shaft motor, motor unit, power simulator, torsion testing device, rotational torsion testing device, tire testing device, linear actuator and vibration device

A dual-axis output and torsion testing technology, which is applied in measuring devices, engine testing, force/torque/power measuring instruments, etc., can solve problems such as leakage operation environment and soil pollution, and achieve higher operating costs, lower operating costs, The effect of power loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

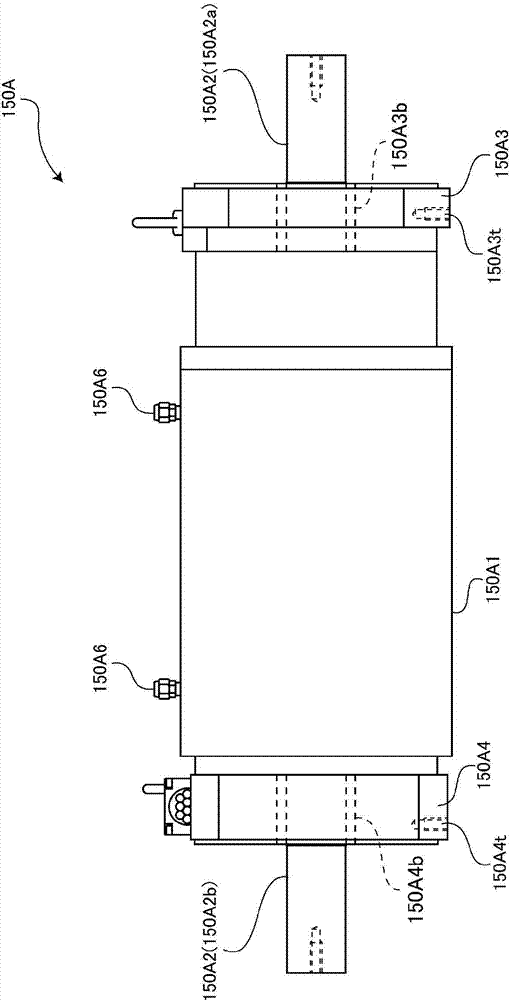

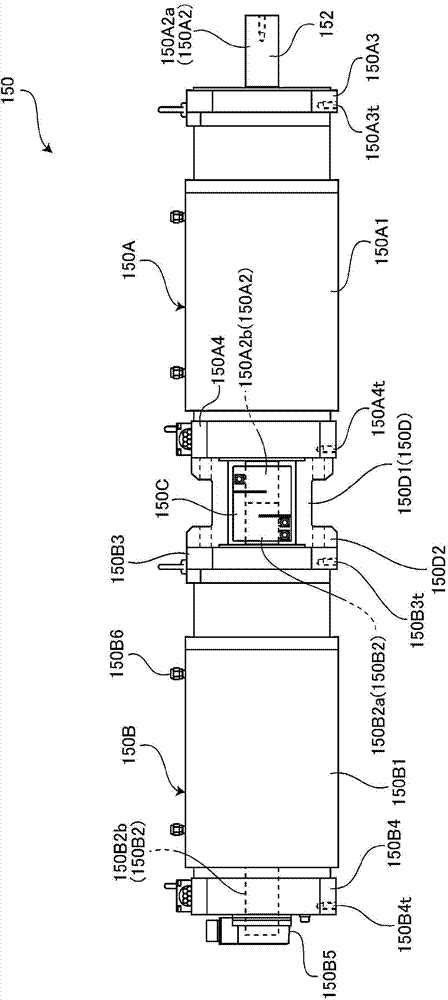

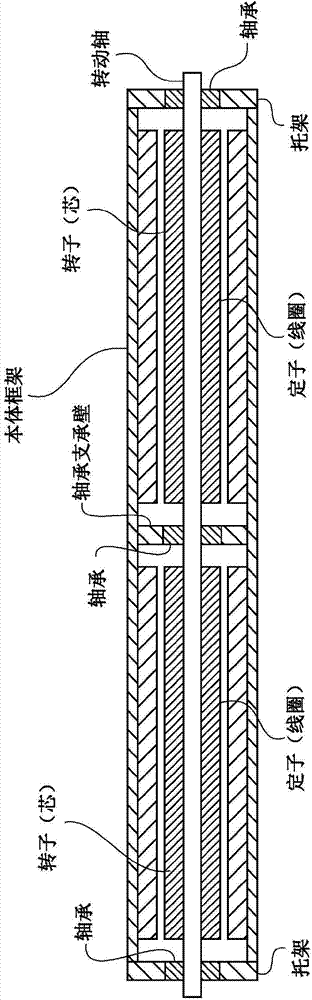

[0079] First, a biaxial output servomotor 150A according to an embodiment of the present invention will be described. figure 1It is a side view of 150 A of two-axis output servo motors. The dual-shaft output servomotor 150A is a high-output (37 kW rated output) ultra-low inertia servomotor provided with two output shafts 150A2a and 150A2b. The dual-axis output servo motor 150A includes a body frame 150A1, a drive shaft 150A2, a first bracket 150A3, and a second bracket 150A4.

[0080] The main body frame 150A1 is a substantially cylindrical frame, and a stator (not shown) having a coil is provided on the inner periphery thereof. A first bracket 150A3 and a second bracket 150A4 are attached to both ends of the body frame 150A1 in the axial direction so as to close the opening of the body frame 150A1 . A motor box is formed by the body frame 150A1, the first bracket 150A3 and the second bracket 150A4. Bearings 150A3b and 150A4b that rotatably support drive shaft 150A2 are pro...

no. 2 approach

[0124] Next, a power cycle rotation torsion test device 1000 according to a second embodiment of the present invention will be described. Rotation and torsion test device 1000 is a device for performing a rotation and torsion test on a propeller shaft for an automobile as a test object T2, and can rotate the propeller shaft to apply a predetermined fixation between the input shaft and the output shaft of the propeller shaft. or variable torque. Figure 11 is a top view of the rotation torsion test device 1000. Figure 12 is a side view of the rotation torsion testing device 1000 ( Figure 11 in the figure on the upper side viewed from the lower side). also, Figure 13 It is a longitudinal sectional view of the vicinity of the load applying part 1100 mentioned later. In addition, the control system of the rotation torsion testing device 1000 has the same Figure 5 The shown first embodiment has the same general configuration.

[0125] like Figure 11 As shown, the rotati...

no. 3 approach

[0134] In the above-mentioned second embodiment, the driving shaft 1212 and the load imparting unit 1100 , the driving shaft 1232 and the driving shaft 1242 arranged in parallel are connected by the driving belts 1192 and 1250 respectively to form a power circulation system. However, the present invention is not limited to this configuration, and a configuration in which power is transmitted using a gear device instead of a drive belt as in the third to seventh embodiments described below is also included in the scope of the present invention.

[0135] Figure 14(a) is a plan view of the torsion testing device according to the third embodiment of the present invention. also, Figure 14 (b) is a side view of the torsion testing device of this embodiment. like Figure 14 As shown, the torsion testing device 100 of this embodiment is configured by fixing a workpiece rotation servo motor 121 , a torque imparting unit 130 , a first gear box 141 , and a second gear box 142 on a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com