Substrate processing apparatus

A substrate processing device and processing device technology, applied in transportation and packaging, rain/wind shields, building components, etc., can solve the problem of increasing the amount of liquid medicine or pure water used, the complexity of the composition or control mechanism, and the cost of device manufacturing Improvement and other issues, to achieve the effect of saving space, miniaturizing the device, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

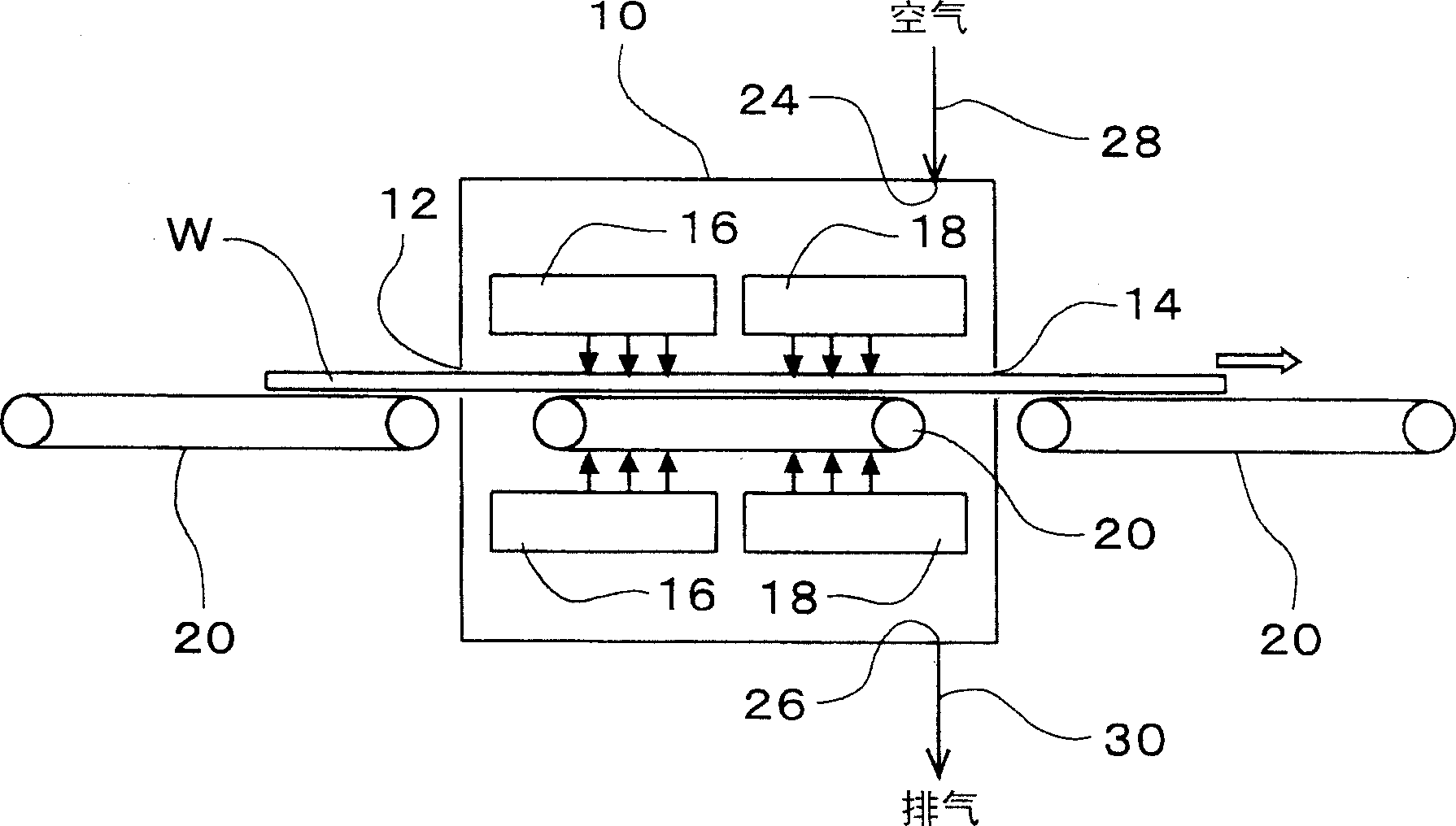

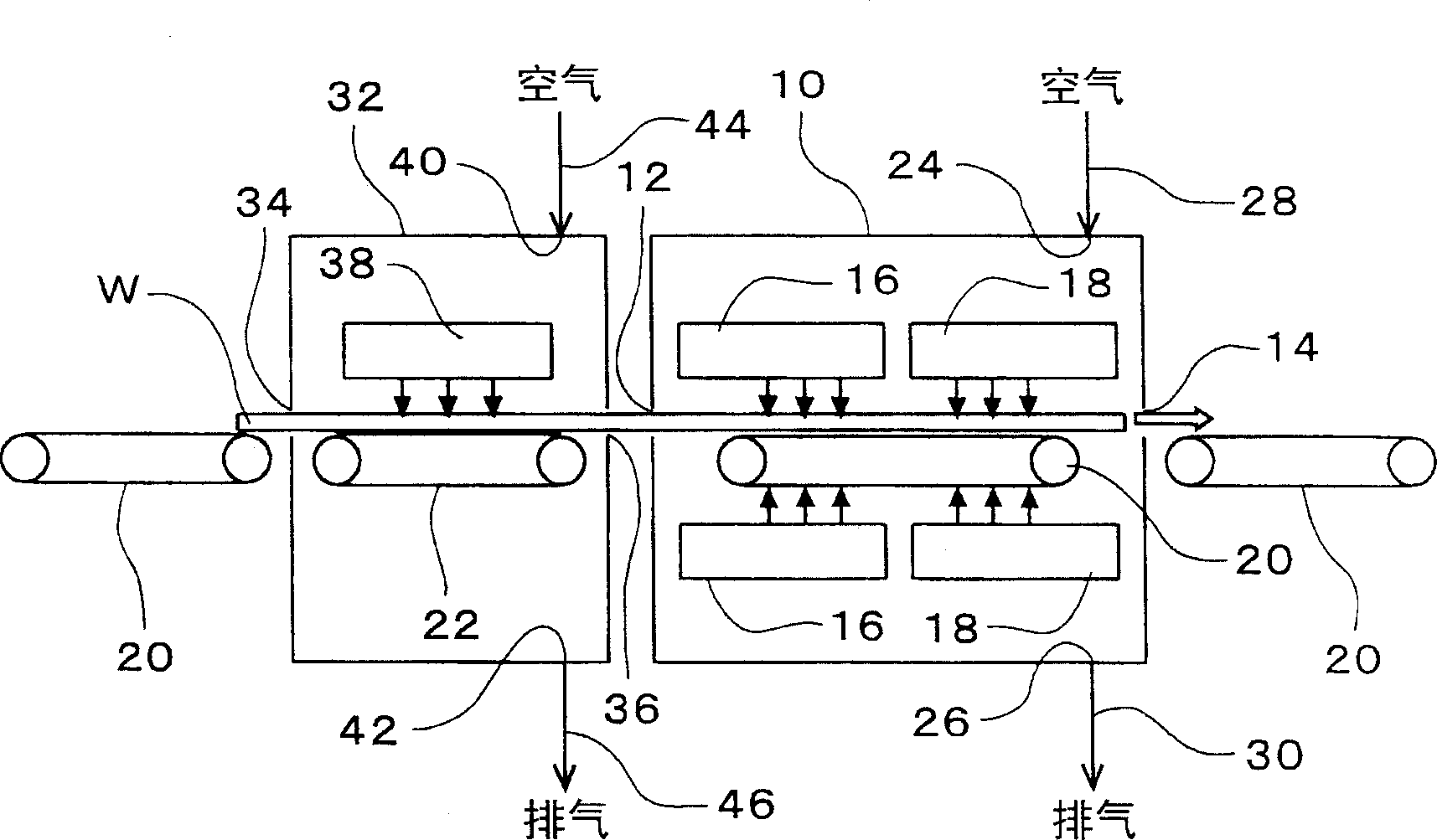

[0031] refer to Figure 1 ~ Figure 1 1 illustrates a preferred embodiment for carrying out the invention.

[0032] figure 1 It is a schematic diagram showing an example of an embodiment of the present invention and a schematic configuration of a substrate processing apparatus.

[0033] This substrate processing apparatus is provided with the airtight processing chamber 10 that has substrate carrying inlet 12 and substrate carrying outlet 14, is equipped with ultrasonic wave · high-pressure jet cleaning · water washing processing part 16 and air knife drying processing part 18 in processing chamber 10, as The substrate W is a processing apparatus for performing predetermined processing. The ultrasonic, high-pressure jet cleaning, and water washing processing unit 16 and the air knife drying processing unit 18 are arranged on the upper side and the lower side of the transport path of the substrate W, respectively. In addition, a roller conveyor 20 is also provided for transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com