Variable displacement swash plate type compressor

A variable and swash plate technology, applied in the direction of liquid variable displacement machinery, mechanical equipment, machine/engine, etc., can solve problems such as reduction, compression reaction force increase, and deterioration of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

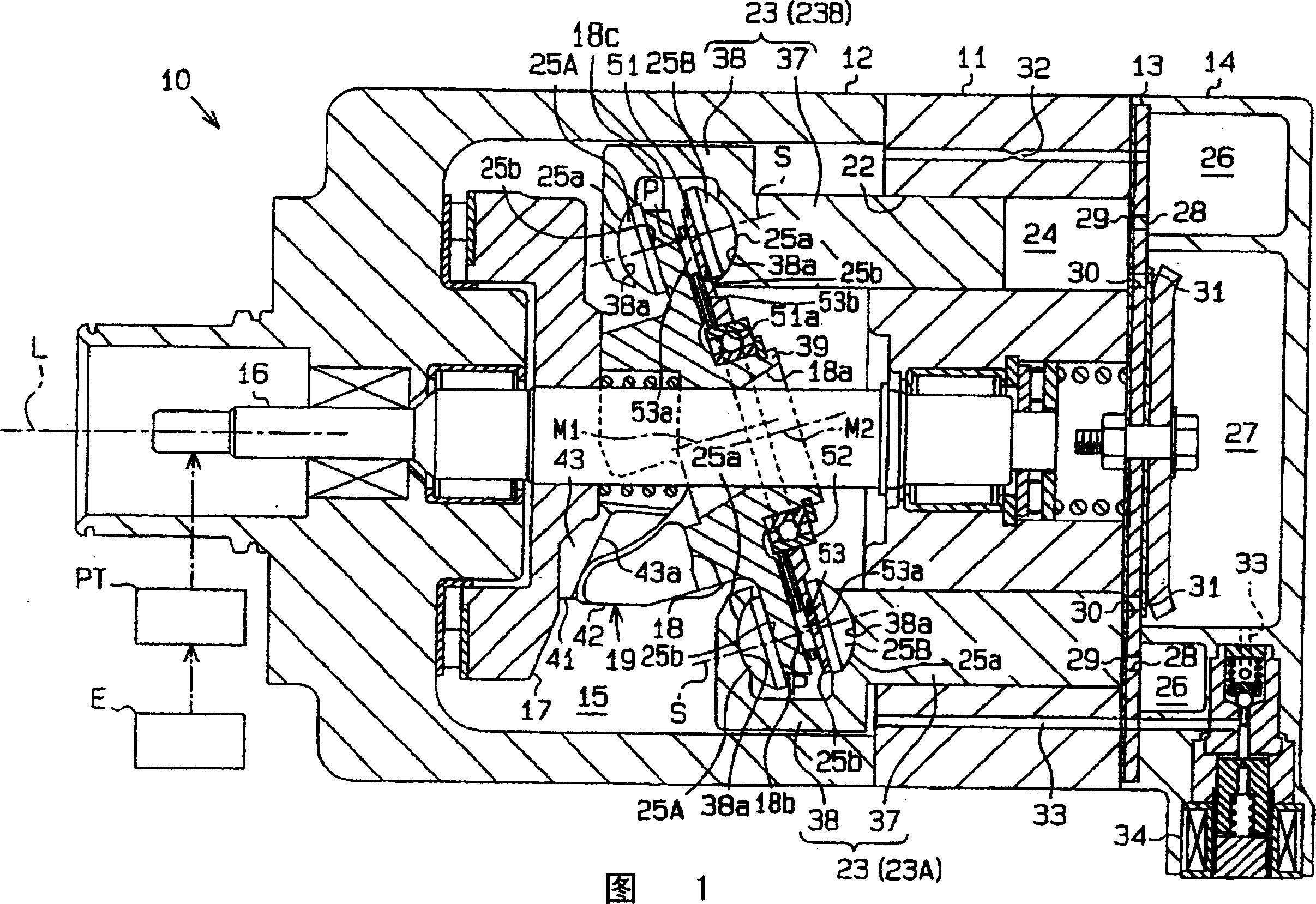

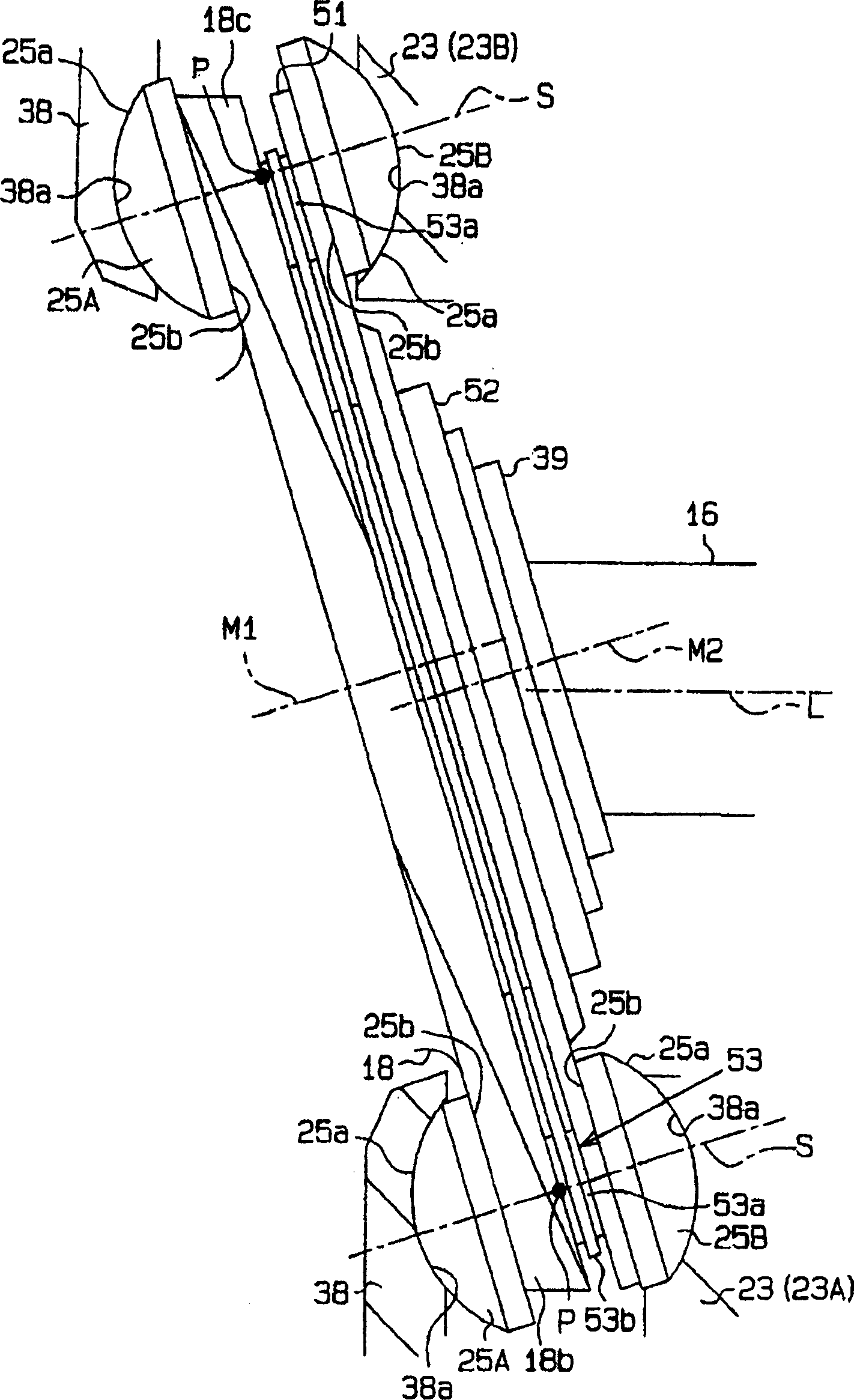

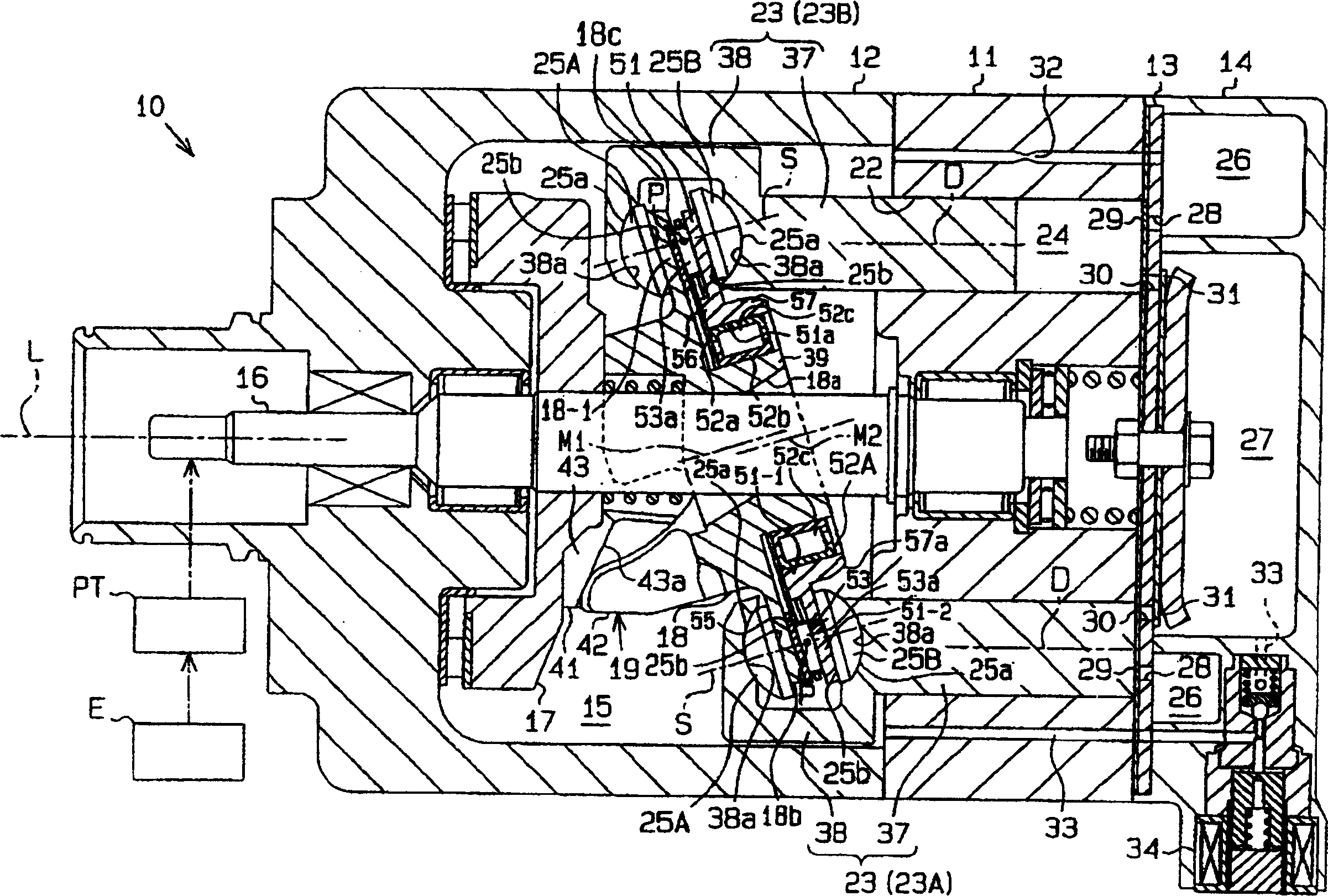

[0037] Next, first to fourth embodiments in which the present invention is embodied as a capacity-variable swash plate compressor constituting a refrigeration circuit of a vehicle air conditioner will be described.

[0038] For the first embodiment, referring to Fig. 1 and figure 2 Be explained. FIG. 1 shows a longitudinal sectional view of a variable capacity swash plate compressor (hereinafter referred to as compressor 10). In FIG. 1 , the left side is the front of the compressor 10 , and the right side is the rear side of the compressor.

[0039] As shown in FIG. 1 , the casing of the compressor 10 is equipped with: a cylinder block 11 , a front casing 12 fixed to the front end of the cylinder block 11 , and a rear end of the cylinder block 11 via a valve and port forming body 13 . ground fixed rear case 14.

[0040] In the casing of the compressor 10 , a crank chamber 15 is defined between the cylinder block 11 and the front casing 12 . A drive shaft 16 is rotatably d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com