Unit brake

a unit brake and brake mechanism technology, applied in the direction of brake arrangement with braking member, braking system, braking components, etc., can solve the problems of adverse effects and cannot be exchanged, and achieve the effect of maintaining the bearing performance of the clutch mechanism and preventing unintentional relaxation of the brake for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

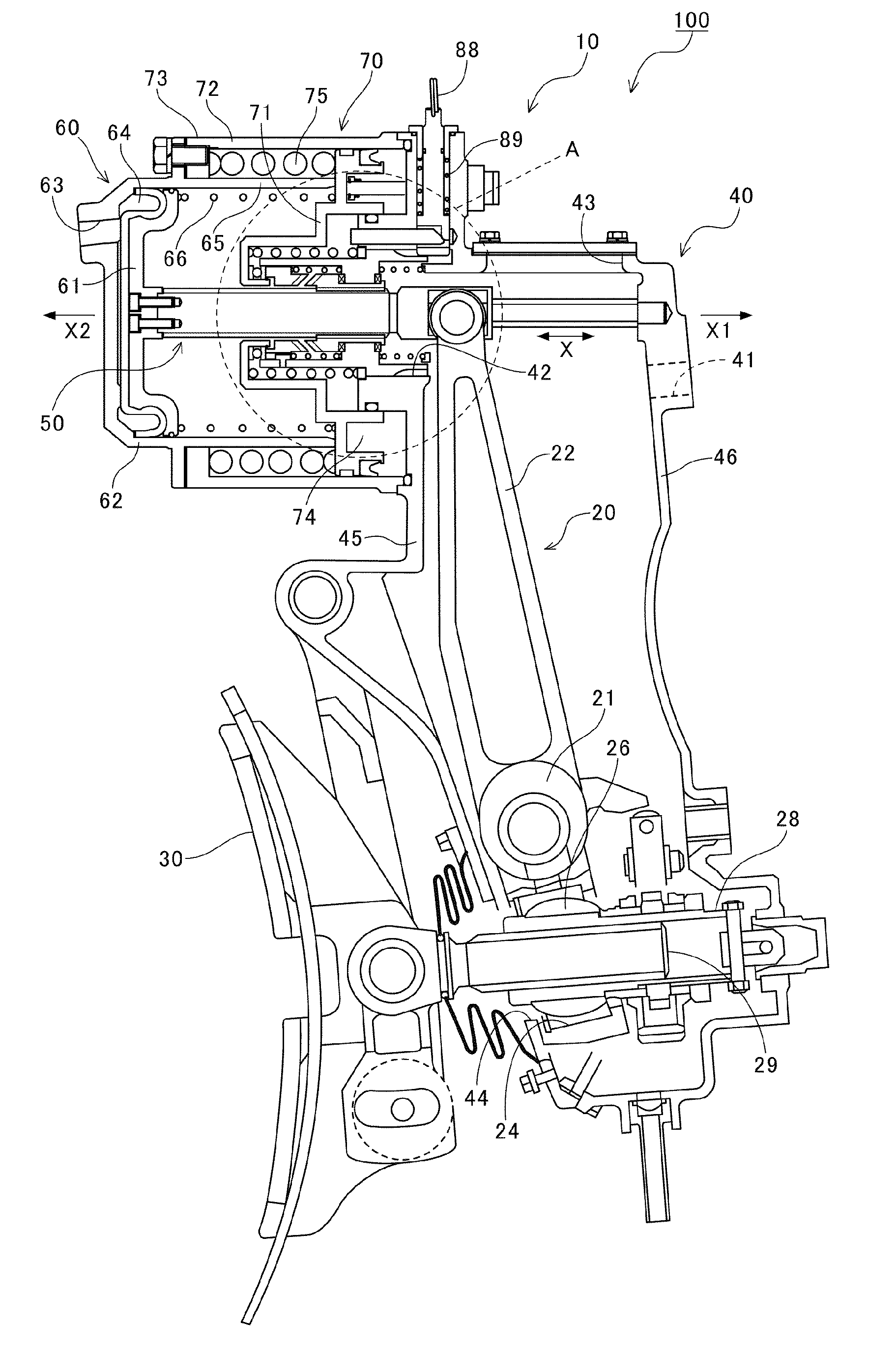

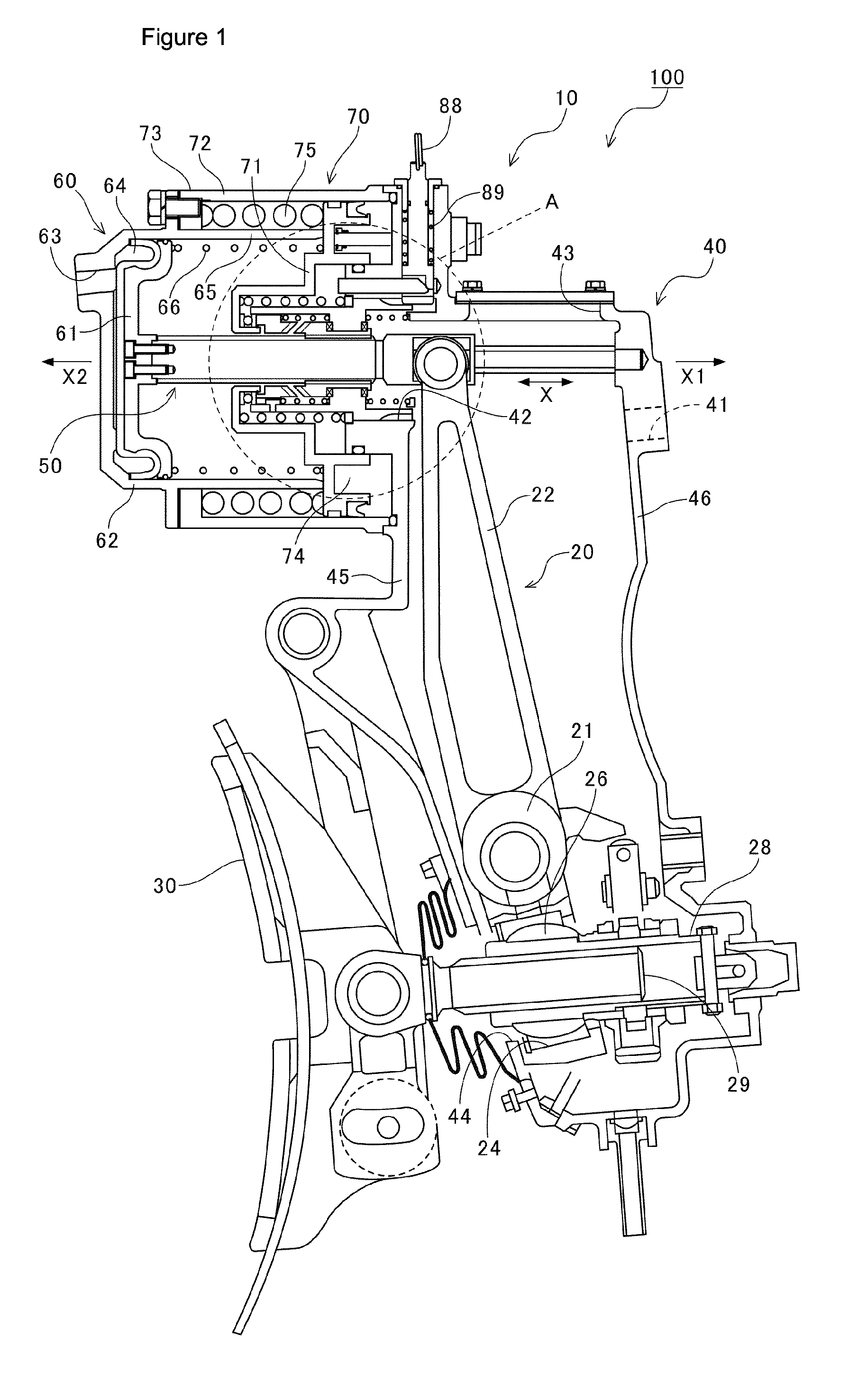

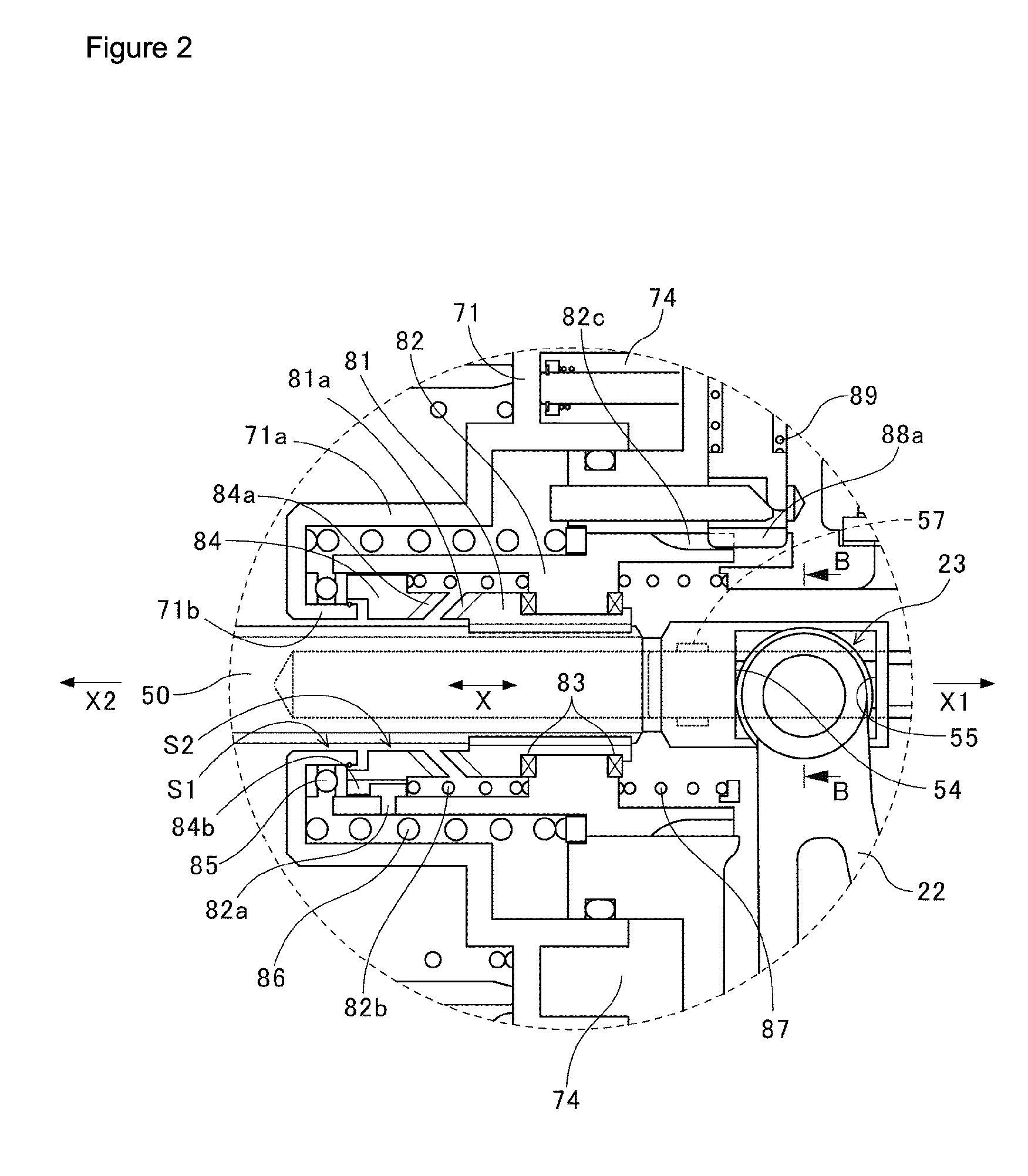

[0043]Here follows a description of the unit brake related to the Embodiment of this Invention, with reference to the illustrations.

[0044]100>

[0045]The unit brake 100 related to the Embodiment of this Invention is configured as a railroad car brake device. This unit brake 100 is equipped mainly with a cylinder device 10 for generating force, a brake lever 20 enabling swivel motion versus the movement of the cylinder device 10, a brake shoe receptacle 30 that can be moved forward and back by the swivel motion of the brake lever 20, and on which is mounted a brake shoe not shown in the illustration, a casing 40 that is formed in a hollow shape, and with an interior that enables communication with the atmosphere. In this casing 40, a connection hole 41 is formed, and a bolt not shown in the illustration inserted into this connection hole 41 is set so that the casing 40 can be fixed to a vehicle carriage.

[0046]20>

[0047]The brake lever 20 is housed in the casing 40. This brake lever 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com