Low-power radial welding bogie

A bogie, low power technology, applied in the direction of the bogie, the device for the lateral relative movement between the chassis and the bogie, the railway braking system, etc., can solve the problem of large vertical stiffness, large unsprung mass, heavy weight, etc. problem, to achieve the effect of reducing the wheel-rail force, reducing the unsprung mass, and reducing weight and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

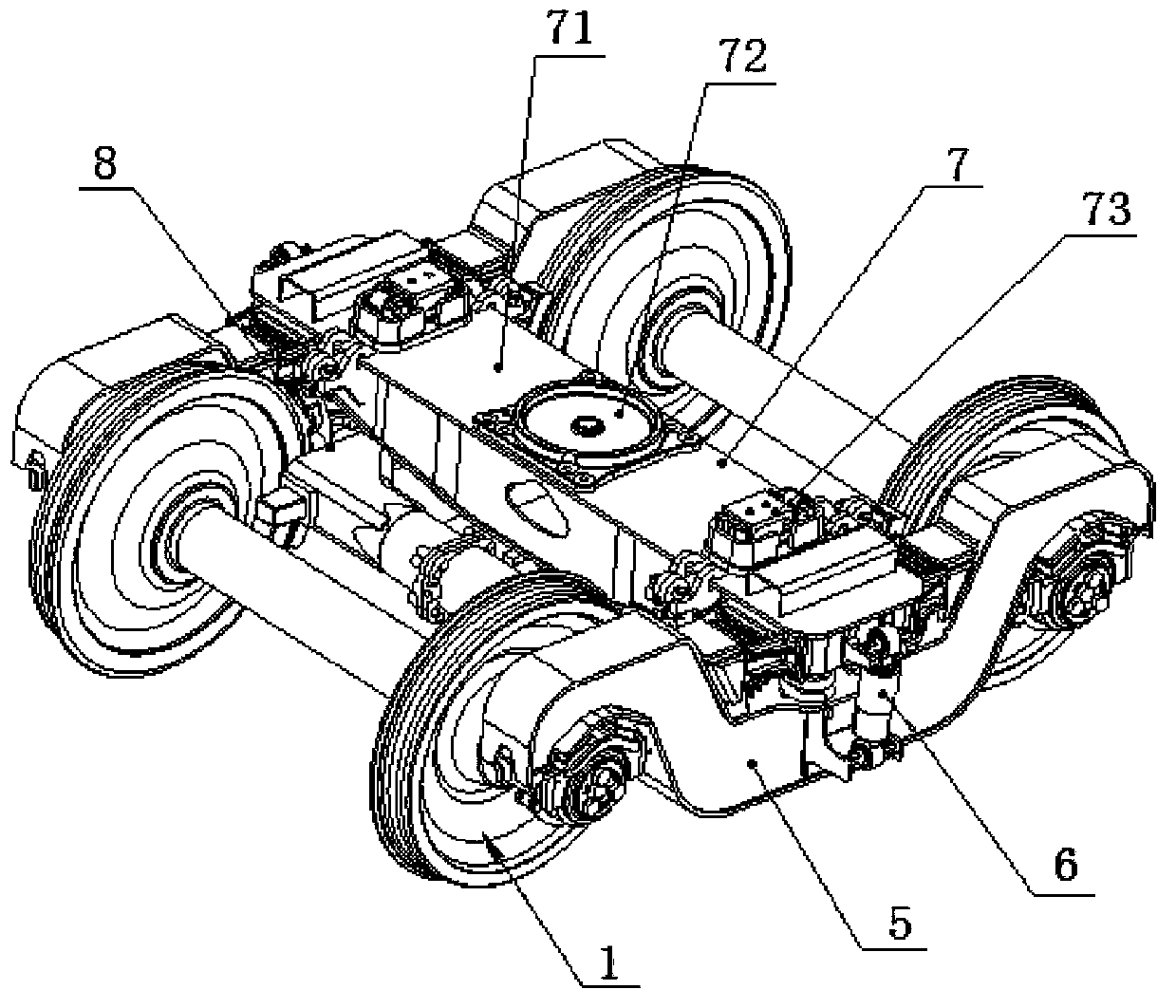

[0042] figure 1 Shown is the structural representation of the present invention.

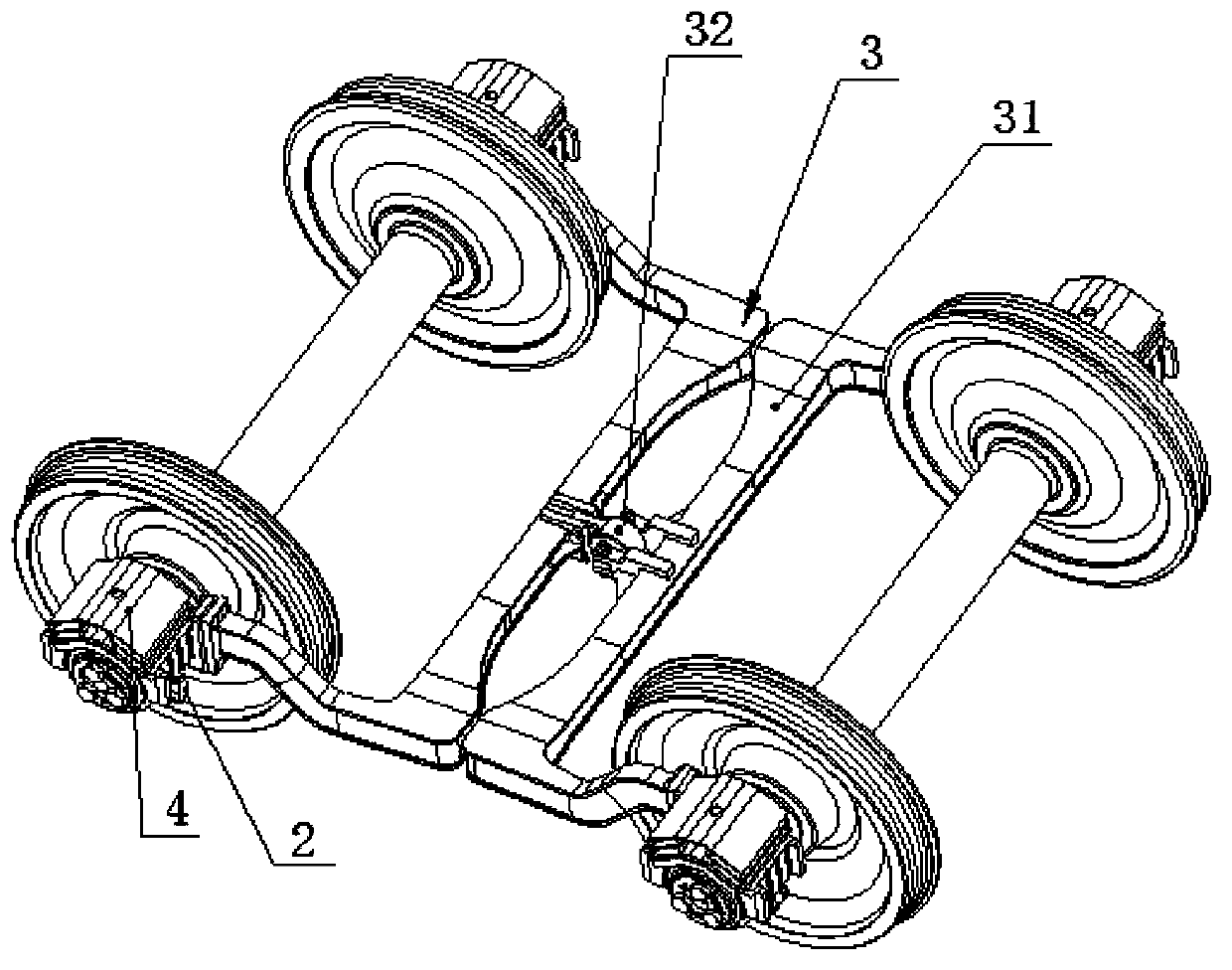

[0043]The present invention adopts a welding three-piece structure, including two wheel sets 1, four bearing saddles 2, a wheel set connection device 3, four primary rubber stacks 4, a side beam 5, and two secondary suspension systems 6, a crossbeam composition 7, a foundation braking device 8 .

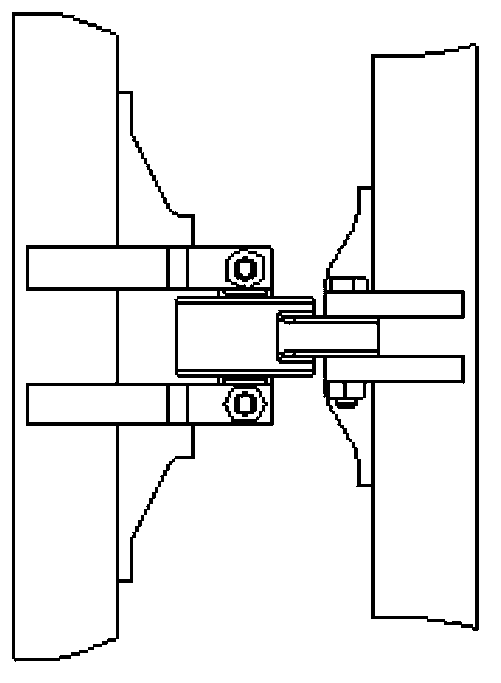

[0044] The side beam 5 is a U-shaped welded structure as a whole, and its two ends are respectively connected to the wheel set 1 through a series of rubber piles 4 and bearing saddles 2; The rubber pile 4 is arranged on the bearing saddle 2 .

[0045] The beam assembly 7 includes a beam 71 , a lower center plate 72 and a side bearing 73 .

[0046] The crossbeam 71 is an integral welded structure, on which a lower center plate 72 and side bearings 73 are arranged, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com