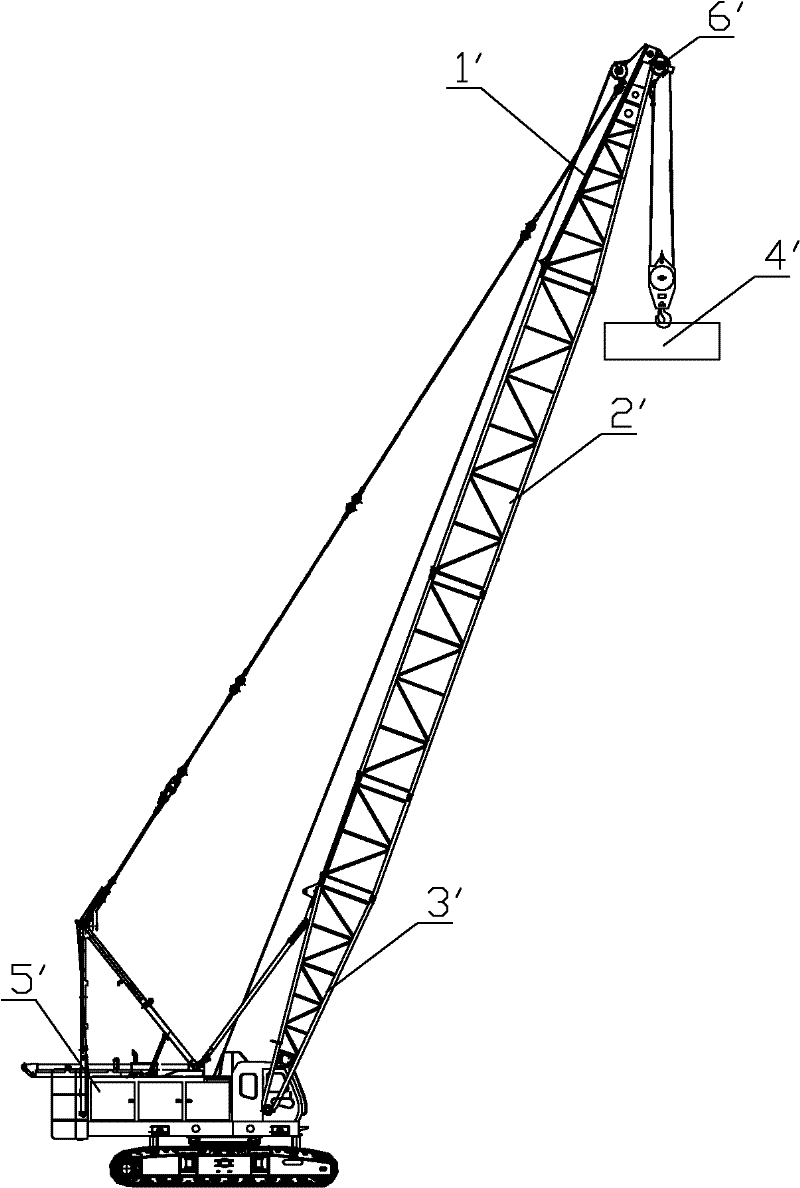

Dynamic compaction machine and arm rack device thereof

A technology of dynamic tamping machine and jib, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve the problems of reducing the 4' effective working height of the rammer, difficulty in fully utilizing the space, and low working efficiency of the dynamic tamping machine. , to avoid motion interference, increase safety, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core purpose of the present invention is to provide an arm support device of a dynamic compaction machine, which can effectively improve the working efficiency of the dynamic compaction machine. In addition, another core of the present invention is to provide a dynamic compaction machine including the above-mentioned boom device.

[0031] Without loss of generality, the present invention takes the boom device installed on a dynamic compaction machine with the car body of a crawler crane as the chassis as an example. It should be understood that the boom device of the present invention can also be arranged on other types of car bodies middle.

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

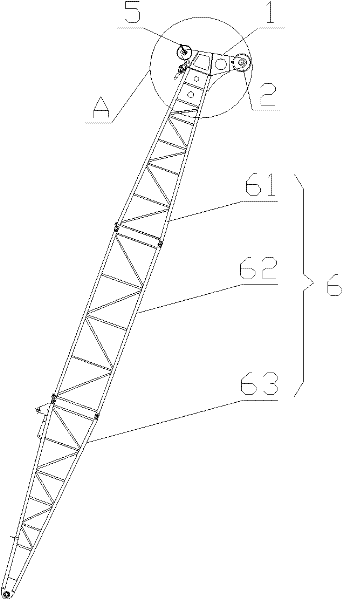

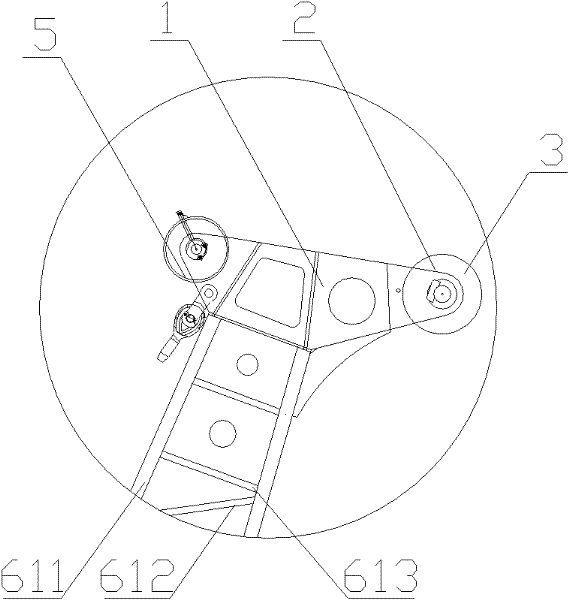

[0033] Please refer to figure 2 and image 3 , figure 2 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com