Flanging and punching die

A punching and die technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing processes, unable to flange and complete side punching at the same time, saving processes and avoiding motion interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

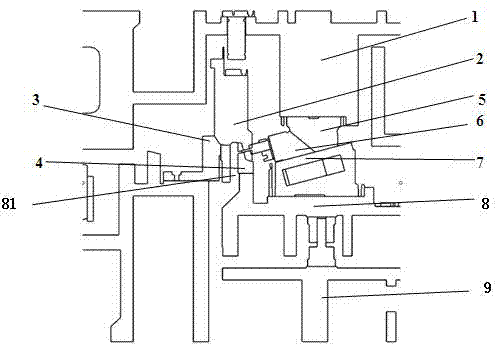

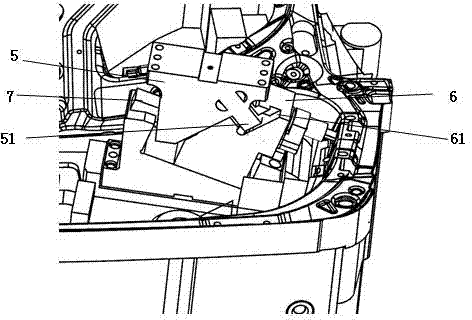

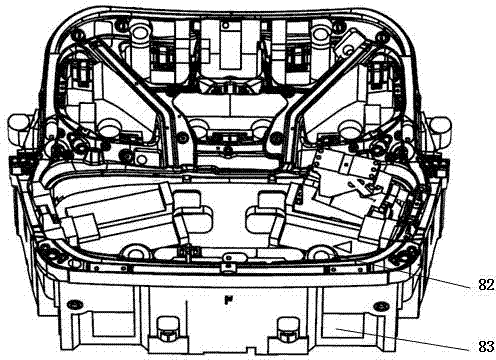

[0016] Figure 1 to Figure 3 The reference numerals in the figure are: upper mold base 1; upper mold pressing core 2; upper flanging knife block 3; lower mold side punching die insert 4; Forced retraction hook 51; side punching wedge 6; side punching wedge forced retraction groove 61; side punching wedge guide post 7; lower mold pressing core 8; punching waste sliding channel 81; guide plate 82; guide Hole 83; Lower mold base 9.

[0017] Such as Figure 1 to Figure 3 As shown, a flanging punching die includes an upper mold base 1 and a lower mold base 9, the upper mold base 1 is connected with an upper mold pressing material core 2, and the lower mold base 9 is connected with a lower mold pressing material core 8, The upper mold base 1 is connected with an upper mold side punching driving block 5, and the upper mold side punching driving blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com