Triaxial differential type pipe creeping device

A pipeline crawler, differential technology, applied in the direction of special pipes, pipe components, pipes/pipe joints/pipes, etc., can solve the problems of increasing friction and wear of the input power transmission pair, high cost, complex structure, etc. Transmission efficiency and drag capability, reduced friction and wear, and small power-to-volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below using the accompanying drawings and examples.

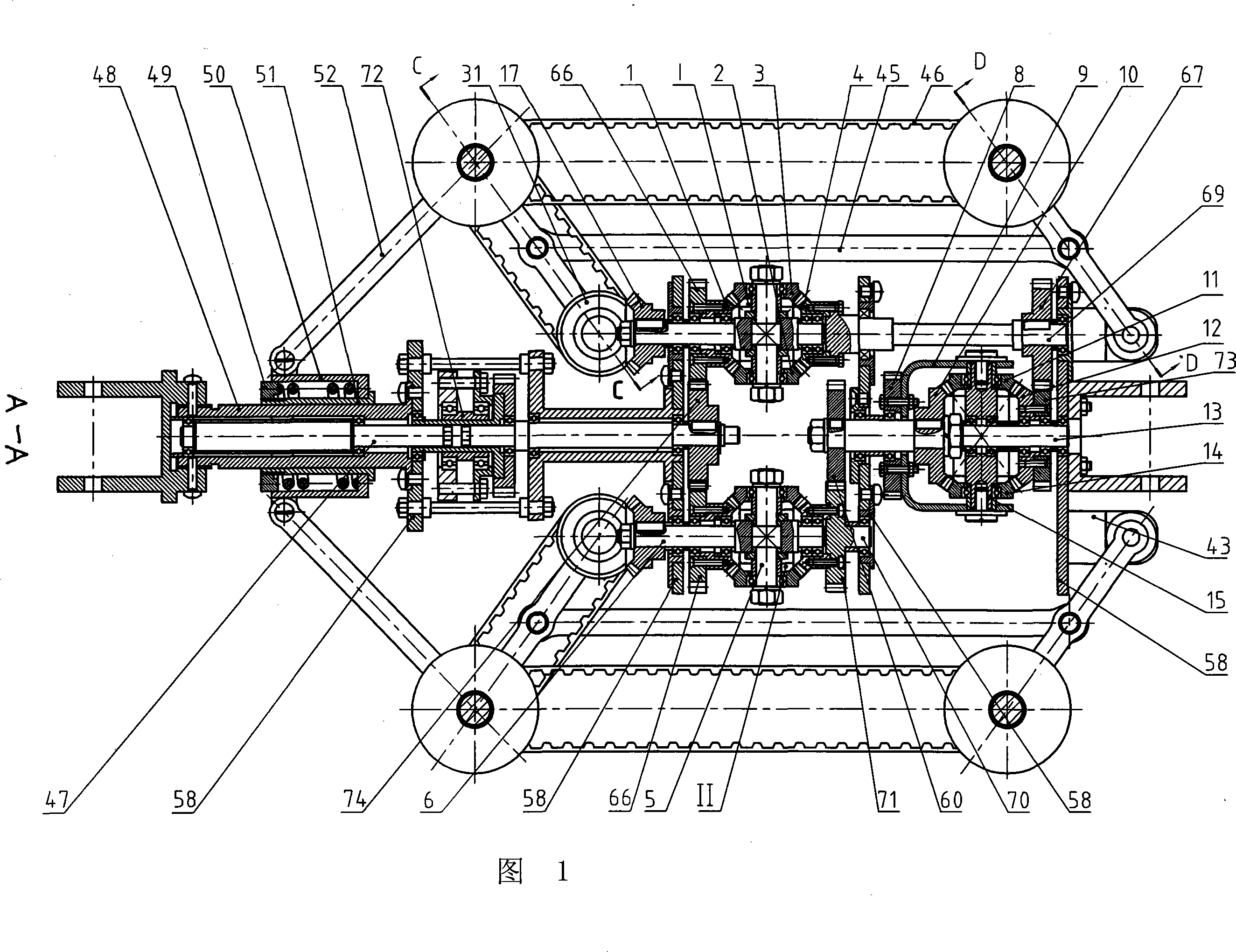

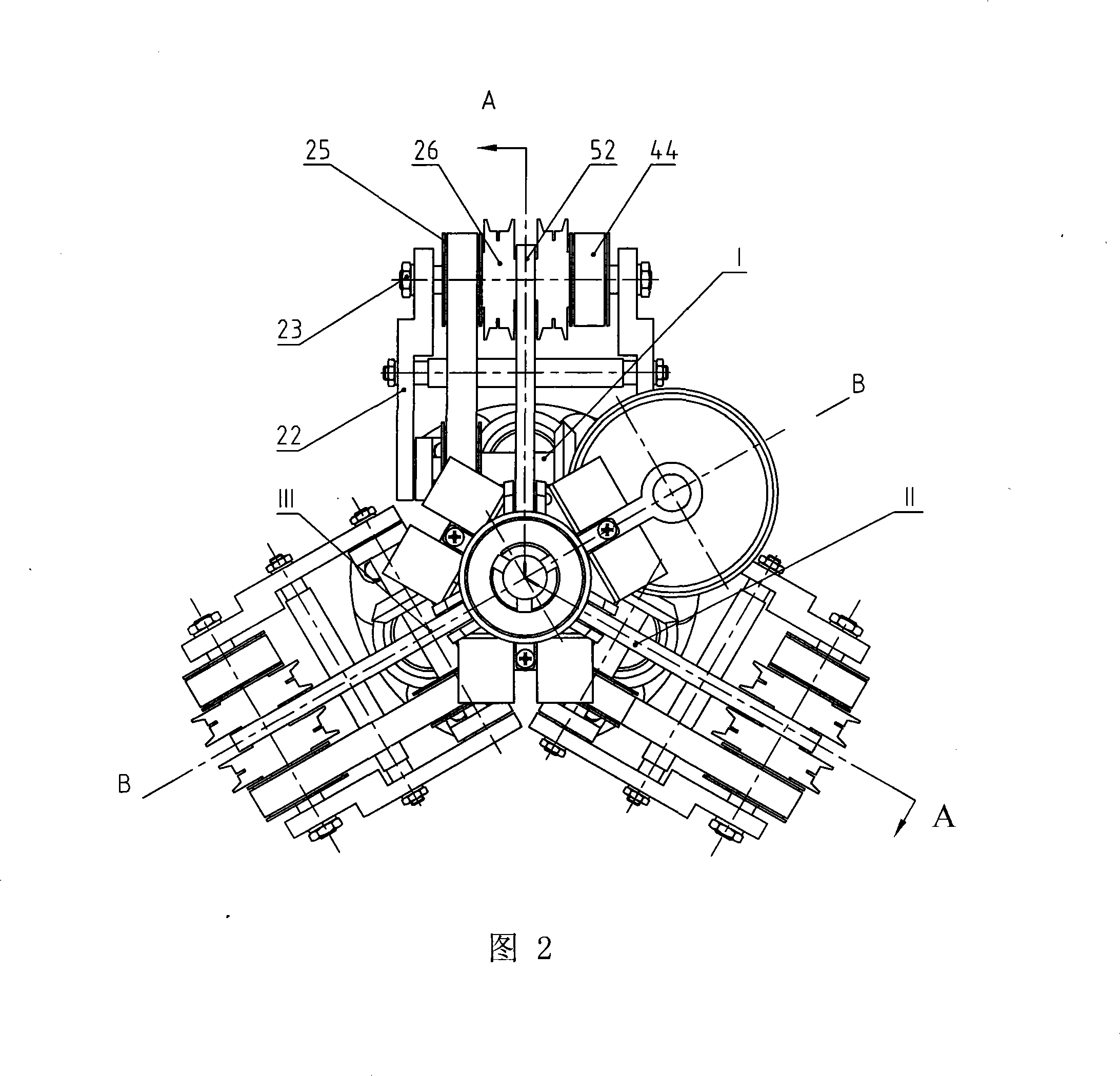

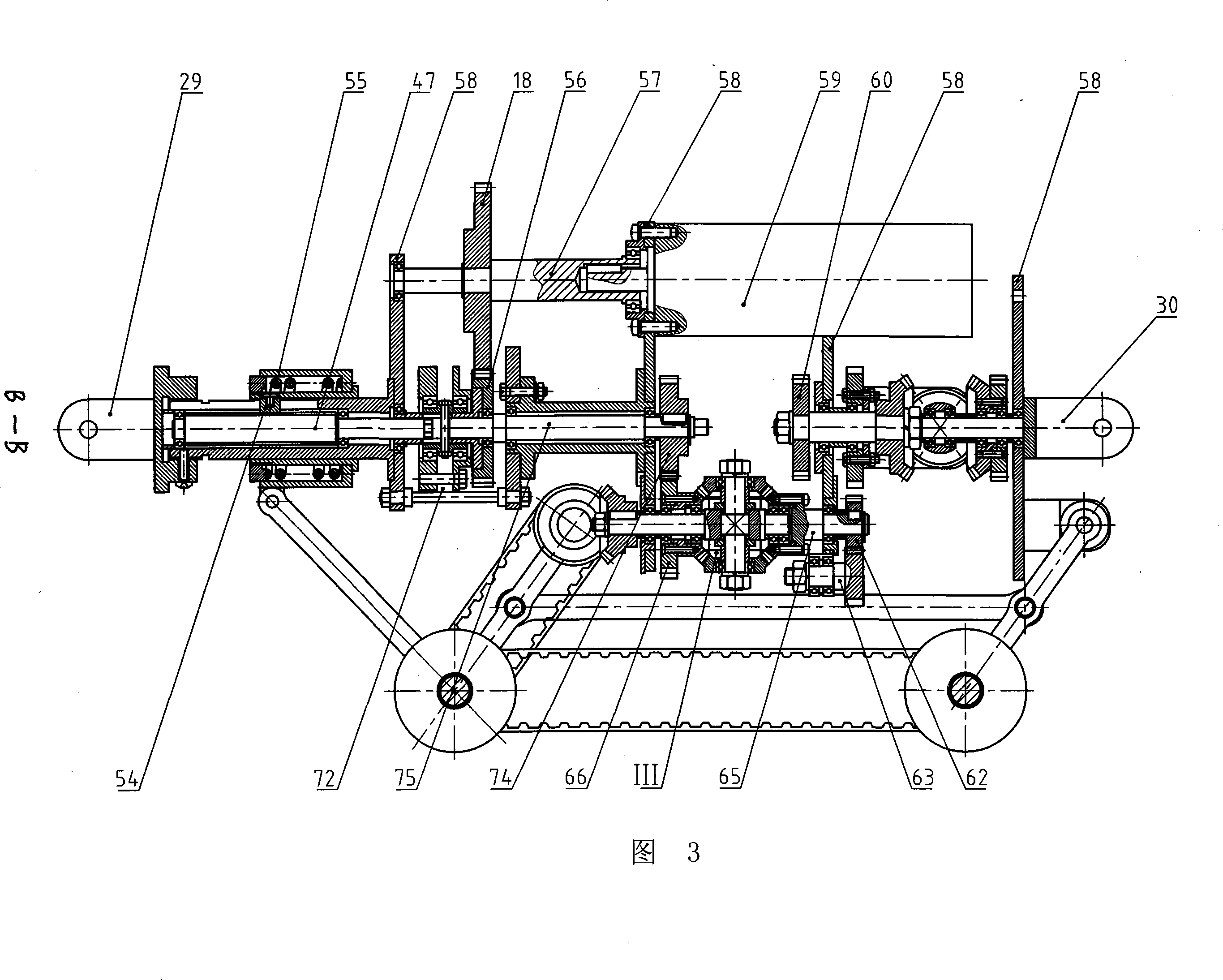

[0018] Referring to Figures 1-3, the three-axis differential pipeline crawler has three differentials I, II, and III with the same structure. The structure of the differential is: a differential cross shaft 6 is mounted on the supporting housing 58, and the first bevel gear 1 and the fourth bevel gear 4 of the differential are mounted on the cross shaft 6 of the differential. The second bevel gear 2 of the differential and the third bevel gear 3 of the differential are housed on the vertical axis 5 of the differential that is intersected by the horizontal axis 6 of the differential, and the first bevel gear 1 and the fourth bevel gear 4 of the differential are respectively It meshes with the second bevel gear 2 of the differential and the third bevel gear 3 of the differential, and a power input gear 66 that is fixedly connected with the first bevel gear 1 of the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com