Midline deviation rectifying method for sedimentary offset ballastless track

A ballastless track and centerline technology, applied in tracks, track laying, track maintenance, etc., can solve the problems of low construction control accuracy, low construction efficiency, and high requirements for curtain setting, so as to reduce the difficulty and cost of rectification operations and reduce reaction forces. Device settings, easy and quick work effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

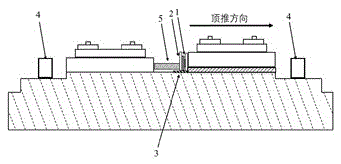

[0020] Embodiment 1: The embodiment of the present invention provides a method for rectifying and repairing the center line of the settled ballastless track in the straight section of the high-speed railway subgrade. The method includes the following contents:

[0021] (1) The grouting lifting material used is foamed polyurethane rapid hardening material, the working time is 6s, the compressive strength reaches 90% of the design strength in 1h, and the ratio of shear strength to compressive strength of the material is 0.02;

[0022] (2) Before construction, check the alignment data of the ballastless track in the section to be corrected, number each rail platform, establish a measurement control network, and determine the amount of lift and correction. The center line shifts to the outside of the line in this section, and the design correction amount and design lift amount of the track support platform in the line deviation correction section 1# to 40# are shown in Table 1.

...

Embodiment 2

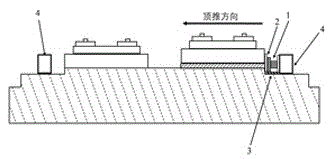

[0037] Embodiment 2: The embodiment of the present invention provides a method for rectifying and repairing the center line of the settled ballastless track in the curved section of the high-speed railway subgrade. The method includes the following contents:

[0038] (1) The grouting lifting material used is sulfoaluminate rapid hardening material, the working time is 200s, the compressive strength reaches 55% of the design strength in 1h, and the ratio of material shear strength to compressive strength is 0.5;

[0039] (2) Before construction, check the alignment data of the ballastless track in the section to be corrected, number each rail platform, establish a measurement control network, and determine the amount of lift and correction. The center line shifts to the inner side of the line in this section, and the designed deviation correction amount and design lift amount of the track support platform in the line deviation correction section 1# to 40# are shown in Table 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com