Forcibly spread frame for a rail vehicle and rail vehicle with such a frame

A technology of frame and vehicle, applied in the field of frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

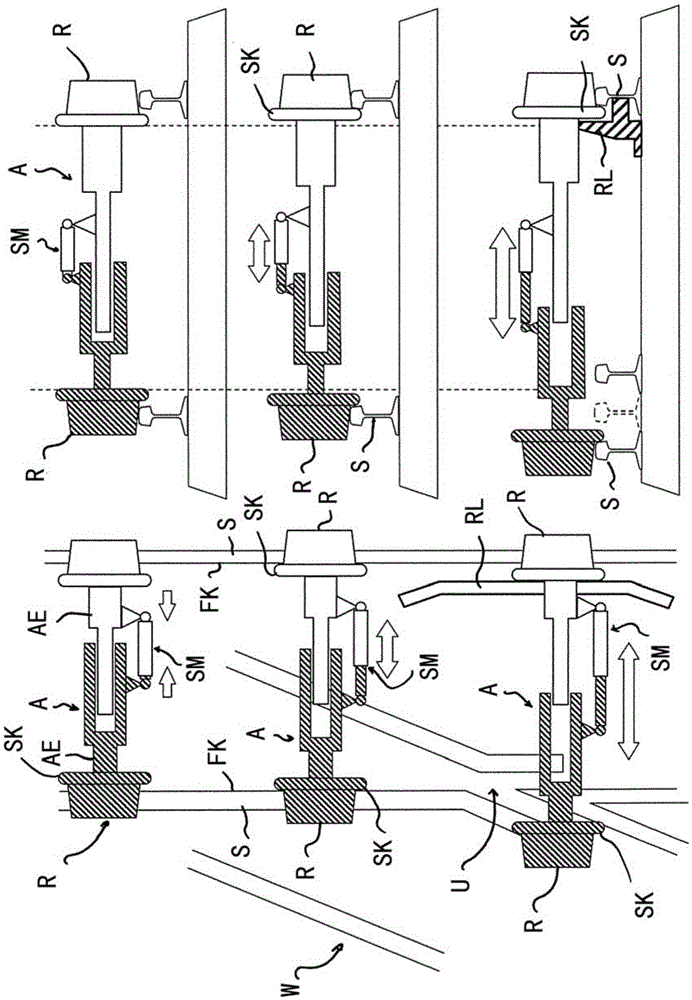

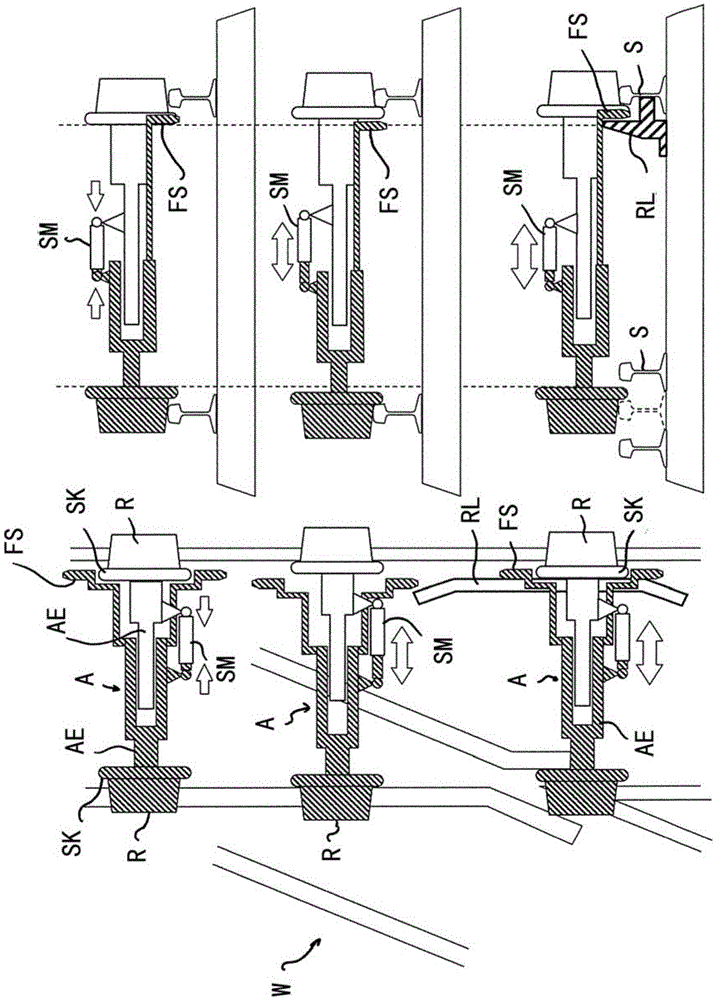

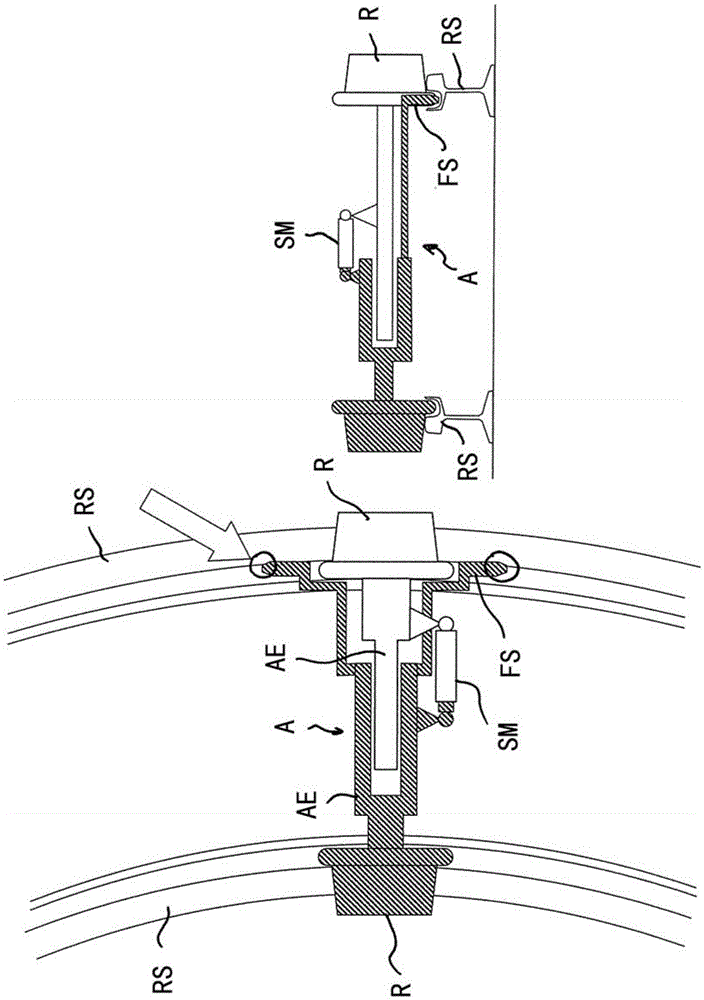

[0089] To describe the problem involved according to the invention, figure 1 The case of a rail vehicle frame passing through a switch is shown schematically, with three axles A extending in each case. The left side of the figure is a schematic top view, and the right side of the figure shows a front view of each axis A respectively corresponding to the axes A shown in the left top view. The extended shafts A are formed in two parts by two shaft elements AE which are relatively movable in the longitudinal direction of each shaft A. The stretch SM (Spreizmittel) engages the two shaft elements AE, and like the middle of the described shaft A shown especially in the figures, the two shaft elements AE press against each other in a way that the rim of the wheel R SK( ) is pressed against the rail edge (Fahrkanten) FK of the rail S, so that the axle A and the frame connected to it are aligned in a fixed orientation of the rail S without lateral play. refer to in figure 1 Axis A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com