Rail track tie

a track tie and rail technology, applied in the field of rail track tie, can solve the problems of unsatisfactory attenuation of mechanical vibration when a train passes over such a track system as presently known, and achieve the effect of limiting fatigue and stress, and improving vibration attenuation performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

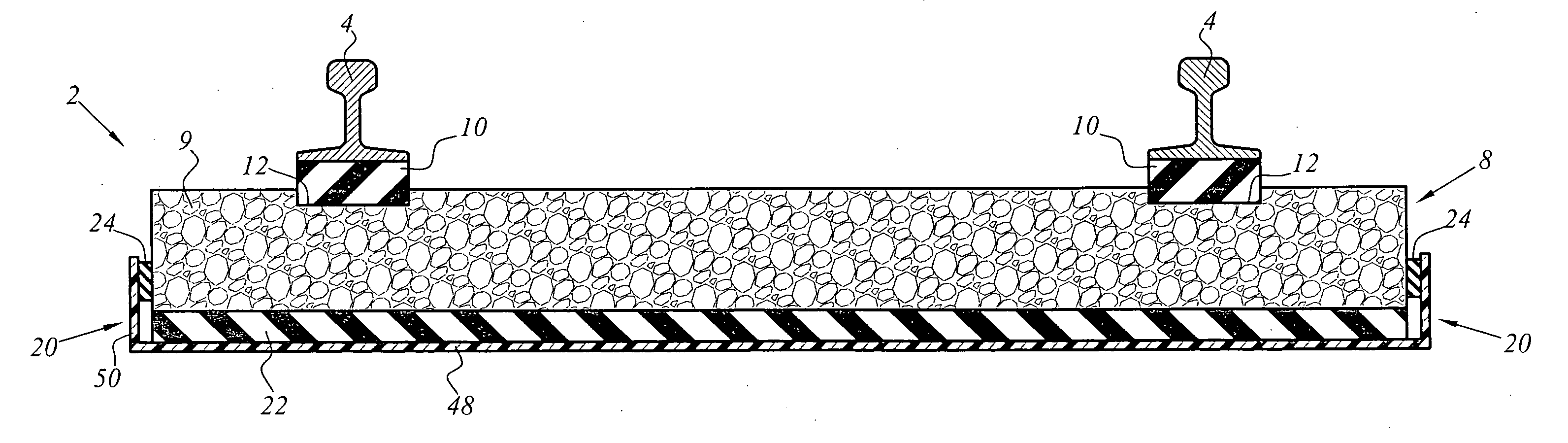

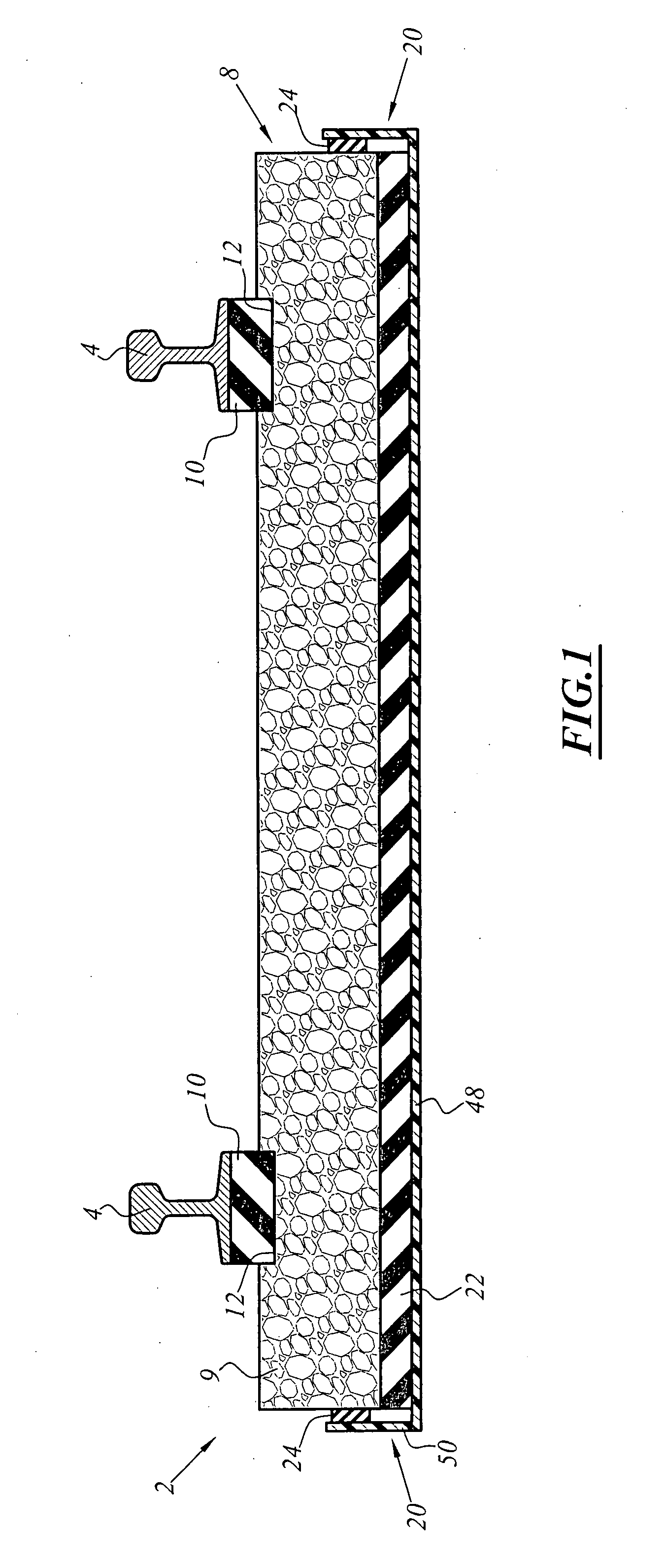

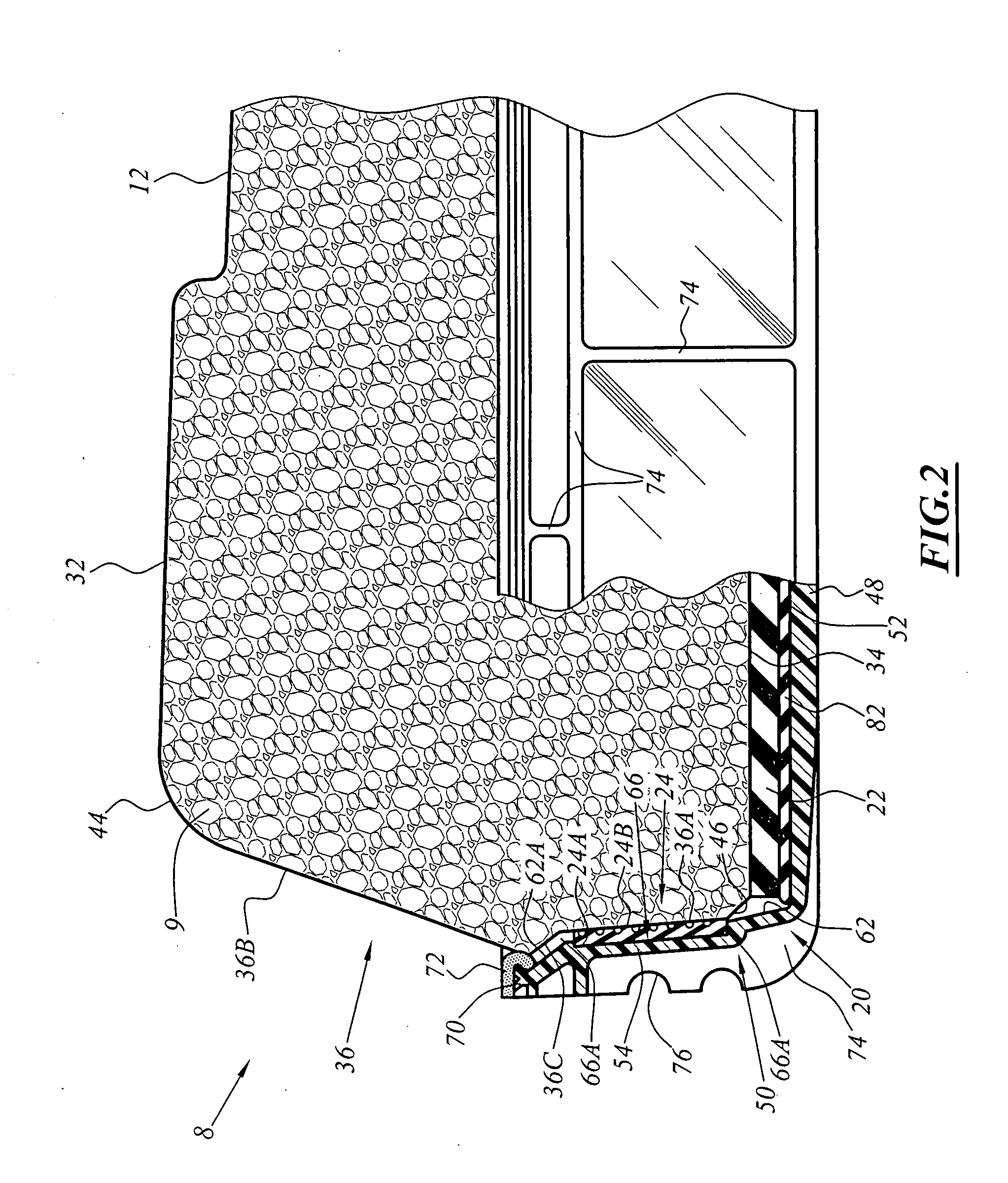

[0030] A segment 2 of rail track in the invention is shown diagrammatically in FIG. 1. The segment 2 comprises two longitudinal rails 4 fastened on a tie 8. The tie 8 comprises a single rigid concrete block 9 and two resilient bearing elements 10 disposed between each rail 4 and the block 9.

[0031] By convention, the longitudinal rails 4 define a reference for the longitudinal direction.

[0032] The resilient bearing elements 10 are substantially in the form of rectangular parallelepipeds. In the example shown in FIG. 1, their width is substantially equal to the width of the base of the rail 4, and their length is substantially equal to the width of the block 9.

[0033] The resilient bearing elements 10 are received in respective recesses 12 in the block 9. The profile of each recess 12 in cross-section is substantially rectangular. The width and the length of each recess 12 in the example shown in FIG. 1 are substantially equal to the width and the length respectively of a resilient b...

second embodiment

[0085] In a second embodiment shown in FIG. 6, the tie 108 comprises two rigid blocks 109 interconnected by a spacer 184. Insofar as the two-block tie 108 is very similar to the single-block tie 8, the same references are used in FIG. 6 as the references used in FIGS. 1 to 4, but with the addition of 100.

[0086] The length of the covers 120 is adapted to receive the blocks 109. The same applies to the transverse pads 126 and the resilient soleplates 122. FIGS. 2 and 3 which show a single-block tie 8 are also entirely applicable for illustrating a tie 108.

[0087] The main difference between the single-block tie 8 and the two-block tie 108 lies in the presence of a spacer 184 penetrating into the two blocks 109.

[0088] The reduction in the dynamic stiffness k2 of the resilient soleplates 122 and / or the increase in the weight of the blocks 109 generate a large longitudinal bending movement.

[0089] Thus, the spacer 184 is of a shape adapted to obtain a second moment of area that is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com