Method for measuring soil water content on site

A soil water content, field technology, applied in measuring devices, by removing certain components, weighing, instruments, etc., can solve the problems of inconsistent drying time control scale, long time consumption, damage to the ring knife, etc., to avoid soil moisture Loss, avoid instrument detection method, avoid the effect of vibration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

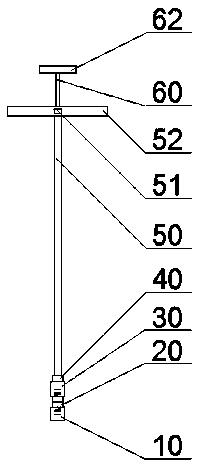

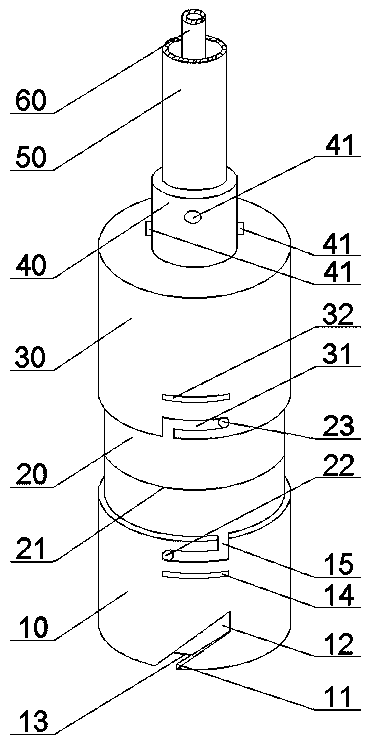

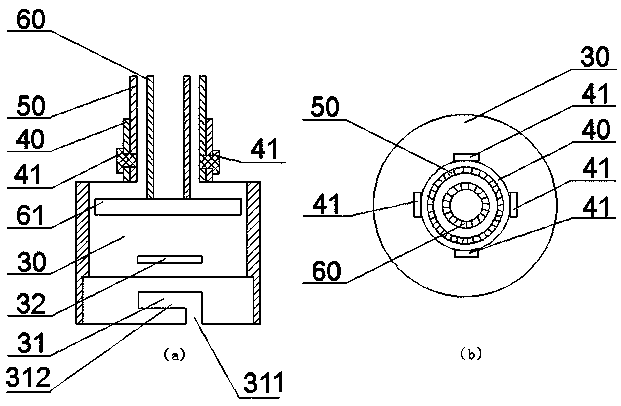

[0046] see figure 1 , figure 2 , image 3 , the present invention adopts special-purpose earth-absorbing equipment for drilling standard volume undisturbed soil to obtain soil without destroying the state of the soil as much as possible. Wherein, the drill bit 10 and the ring cutter 20 are both cylindrical. In the figure, the drill bit 10 is connected to the bottom of the ring cutter 20, and the ring cutter 20 is connected to the bottom of the positioning seat 30, and the positioning seat 30 is connected to the scale rod 50. The scale rod 50 has Scale can indicate the depth of the ring cutter 20 drilling into the soil. The top of the positioning seat 30 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com